Controlling method for coiler bottom layer connection press and polyester fiber coiled in the method

A control method and technology of polyester fibers, which are applied in fiber processing, bundling of newly sprayed filaments, textiles and papermaking, etc. Control, soft feel, increase the effect of the tail rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] For the purpose of full disclosure, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described below are only used to explain the present invention, and are not used to limit the protection scope of the present invention.

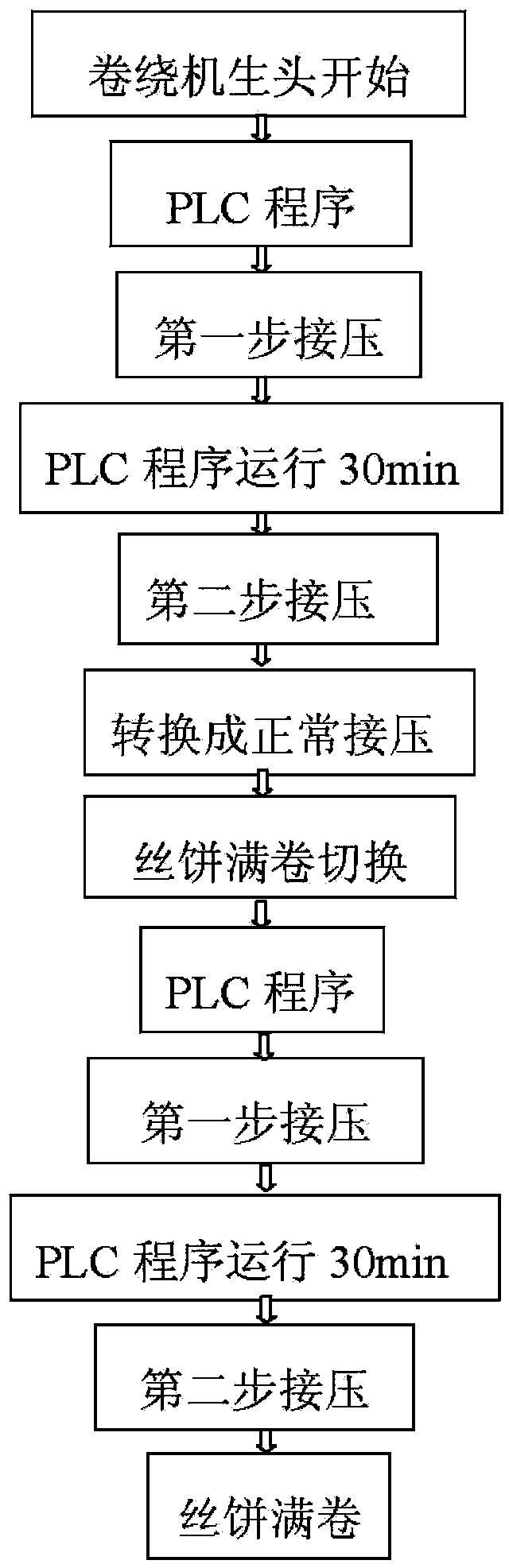

[0026] Such as figure 1 As shown, in the whole packaging process, the bottom layer of the winding machine of the present invention is transformed into a two-step pressure connection, including the following steps:

[0027] (1) The normal threading program of the winding machine remains unchanged, and the PLC program is run to control the first step of pressing when the silk cake is normally wound;

[0028] (2) After completing the first step of crimping in step (1), switch to PLC program control for the second step of crimping, that is, switch to normal winding crimping;

[0029] (3) After the normal winding is full, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com