Suspension overturn type tunnel inverted arch formwork trolley and construction method thereof

A formwork trolley and flip-up technology, applied in tunnels, tunnel linings, earth-moving drilling, etc., can solve the problems of high construction cost, difficult installation, affecting traffic, etc., and achieve the effect of simple construction preparation process and reduced preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

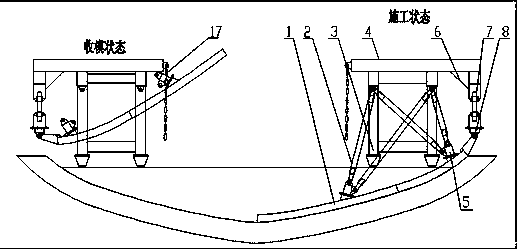

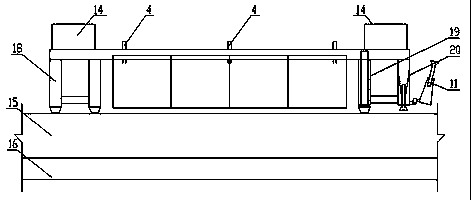

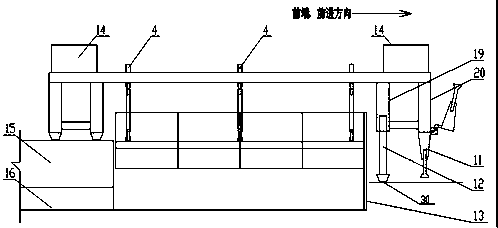

[0044] Below in conjunction with accompanying drawing, the present invention is described in detail.

[0045] A suspended and overturned tunnel inverted arch formwork trolley, which includes an inverted arch formwork 1, and also includes a formwork entry and exit system, a formwork adjustment system, and a walking support frame 3 for supporting the overall weight;

[0046] The entry and exit system of the formwork includes: a chain hoist or an oil cylinder 17, a formwork turning hinge ear beam 8, a formwork connecting beam 5 installed on the inverted arch formwork 1, and the entry and exit system mainly plays a role in the closing state of the present invention. When the mold is retracted, the inverted arch formwork is separated from the filling top surface by a certain height, so that there is room for manual plastering during concrete filling construction;

[0047] The template adjustment system includes: a supporting screw 2, the template connecting beam 5, an adjusting scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com