Foam light soil replacing and filling soft foundation construction method suitable for coastal airport reconstruction and extension project

A foam lightweight soil and airport technology, which is applied in infrastructure engineering, construction, soil protection, etc., to achieve the effects of high reliability, convenient and efficient construction, and smooth construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

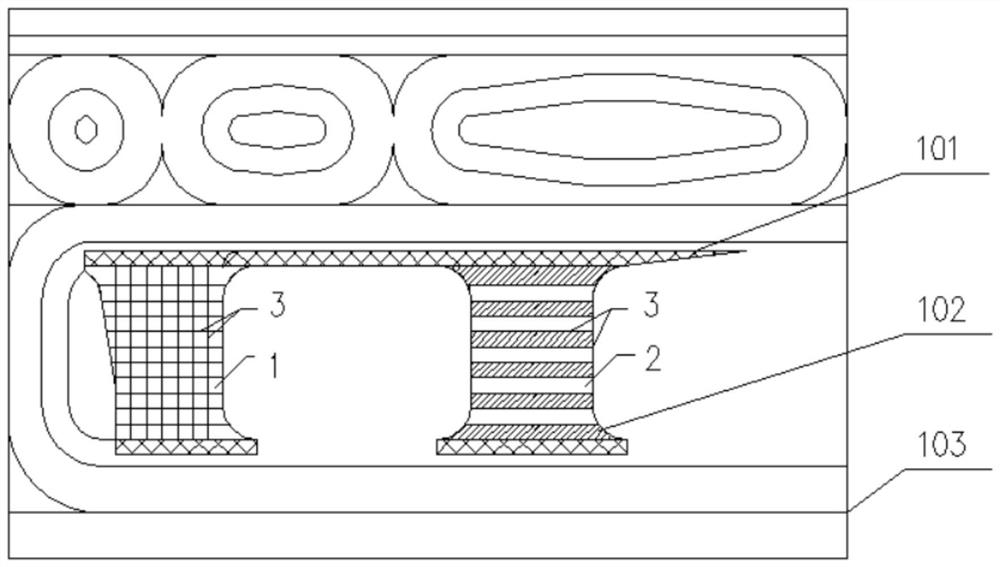

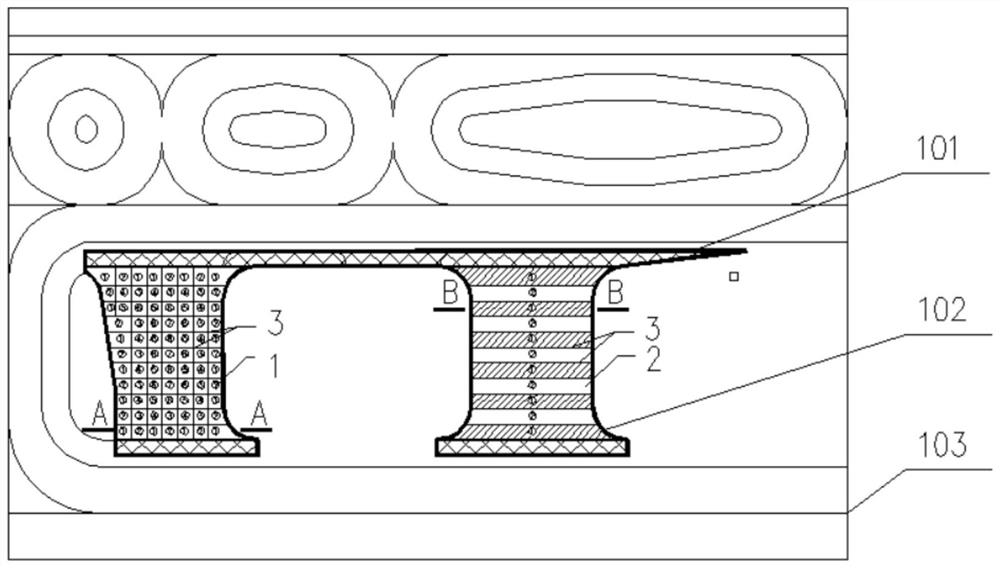

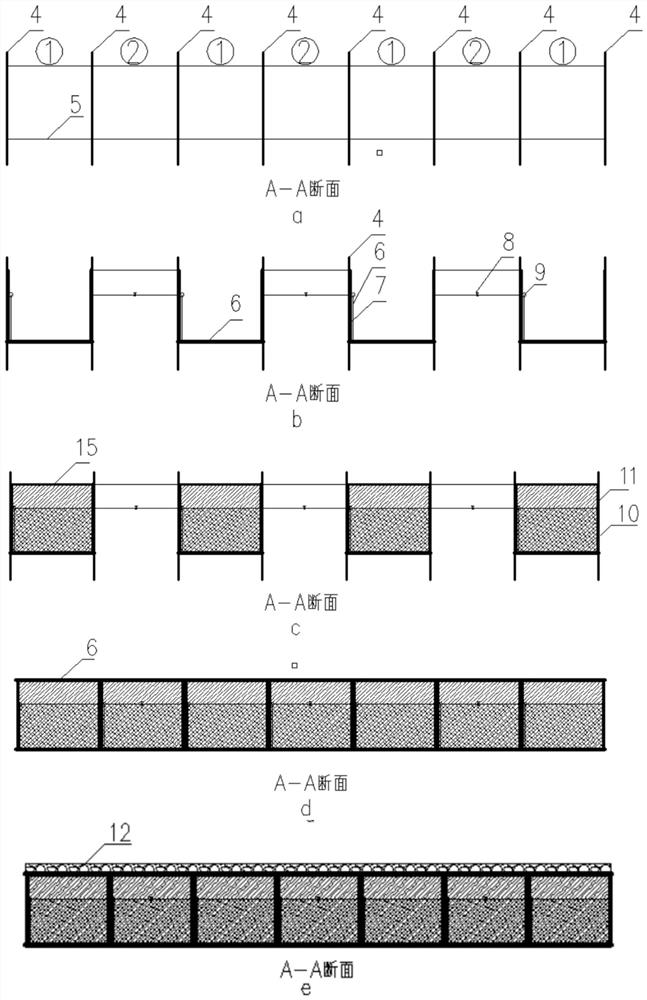

Image

Examples

Embodiment Construction

[0061] The present invention is implemented according to the following steps:

[0062] (1) Carry out measurement and lofting of the area to be treated with soft foundation, and prepare two types of foam light soil with different bulk density above and below water based on the predetermined construction mix ratio; since the groundwater level in the foundation of Linhai Airport is generally high, so , above the groundwater level, use foam light soil above the water, with a bulk density of 7-9kN / m 3 ;Under the groundwater level, underwater foam light soil is used, with a bulk density of 10-12kN / m 3 , and the underwater foam lightweight soil formula contains plasticizers to prevent segregation.

[0063] (2) According to the soil properties, the area 1 with poor soil properties (standard penetration hits <4) within the excavation range is divided into grid-like sub-areas of 10m*10m, and excavation of the foundation pit is carried out by means of jumping grids , the plane excavati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com