Particulate filter carrier of diesel engine

A particulate filter and filter technology, which is applied to machines/engines, mechanical equipment, engine components, etc., can solve problems such as inability to reach diesel engine exhaust emissions, and achieve reasonable distribution of micropore pore size, good capture effect, and increased adsorption time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

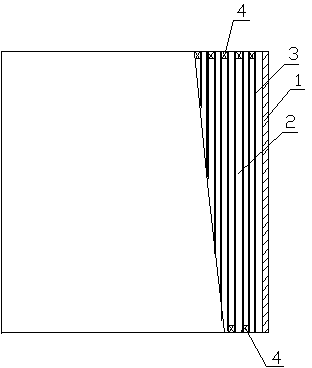

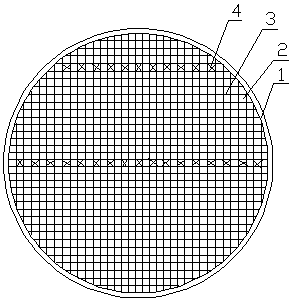

[0024] In Example 1, the diesel particulate filter carrier includes a filter body 1, the filter body is a cylinder, the filter body has honeycomb holes 2 inside, and the surface of the pore walls 3 of the peaks and holes is coated with an active catalyst, The plugs 4 (the shape of the plugs match the honeycomb holes) are alternately pressed into the two ends of the spaced honeycomb holes, and the filter body is made of 87wt% cordierite, 4wt% andalusite, 3wt% silicon carbide and 6wt% The fiber carbon ball mill is mixed, and then 3% of the binder by weight of the above mixture, 2% lubricant and appropriate amount of water are added and prepared according to the following method:

[0025] 1. First process cordierite, andalusite and silicon carbide into powder and sieving.

[0026] 2. According to the above ratio, the processed powders and fiber carbon are dry blended into a dry blend.

[0027] 3. Add bonding agent, lubricant and water to the dry mix to mix and knead to make mud.

[0028...

Embodiment 2

[0033] In Embodiment 2, the diesel particulate filter carrier includes a filter body 1, the filter body is a cylinder, the filter body has honeycomb pores, and the surface of the pore walls 3 of the pits are coated with an active catalyst. The two ends of the spaced honeycomb holes are alternately pressed into plugs 4 (the plug shape matches the honeycomb holes). The filter body is made of 90wt% cordierite, 3wt% andalusite, 3wt% silicon carbide and 4wt% Fibrous carbon ball milling and mixing, adding 3% binder, 2% lubricant and appropriate amount of water from the above mixture, and preparing it as follows:

[0034] 1. First process cordierite, andalusite and silicon carbide into powder and sieving.

[0035] 2. According to the above ratio, the processed powders and fiber carbon are dry blended into a dry blend.

[0036] 3. Add bonding agent, lubricant and water to the dry mix to mix and knead to make mud.

[0037] 4. The stale mud is filtered and extruded into a wet billet.

[0038] 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap