Centrifugal Pitch Wind Turbine

A technology of wind turbines and centrifuges, applied in wind turbines, control of wind turbines, wind power generation, etc., can solve the problems of high rotational speed, damage to birds, and inability to make it bigger, so as to achieve low noise and damage to birds less, strong wind gust resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

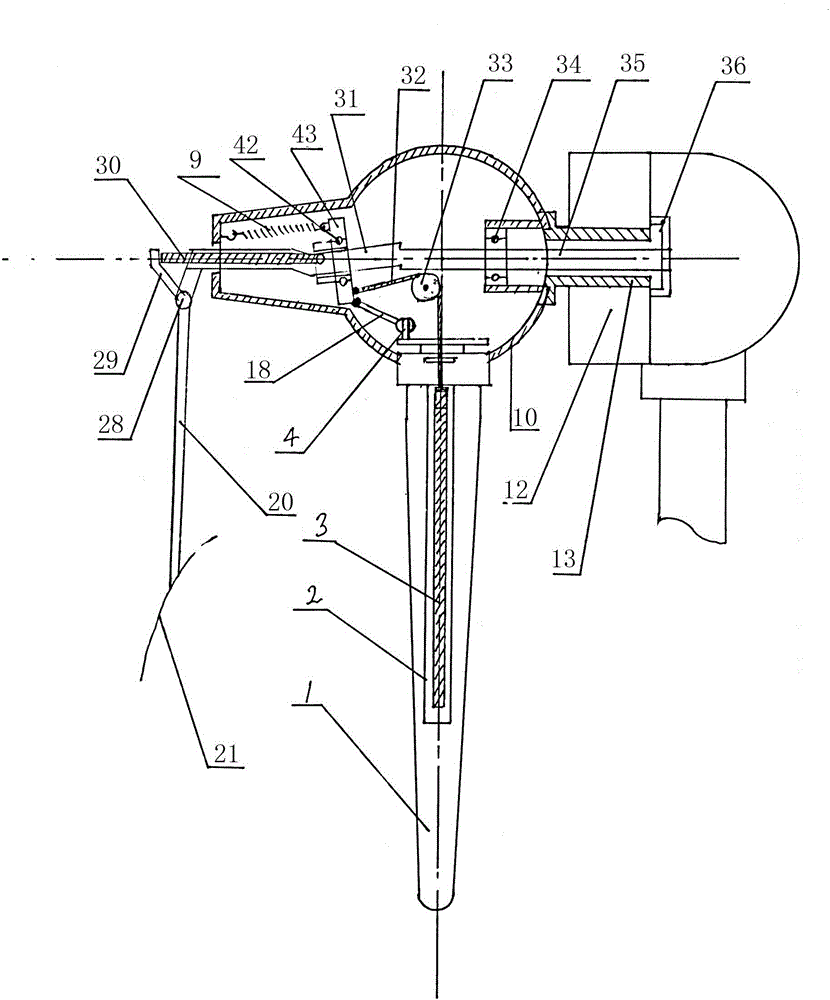

[0018] Such as figure 1 As shown, in the present embodiment, the centrifugal variable pitch wind power generator includes blade 1, generator 12, propeller hub 10, wind speed rudder 21, wind speed rudder stock 20 and wind speed rudder rocker arm 29, wind speed rudder stock 20 and wind speed rudder rocker The arms 29 are connected by the wind speed rudder shaft 28. The centrifugal body sliding sleeve 2 integrated with the blade is arranged in the blade 1. The centrifugal body sliding sleeve is hollow tubular, and a centrifugal body is installed in the centrifugal body sliding sleeve. 3. The centrifugal body 3 slides reciprocally in the centrifugal body sliding sleeve 2, and the centrifugal body is a cylinder. The centrifugal body and the paddle are connected through a wire pulley device.

[0019] The wire pulley device includes a wire rope 32, a fixed pulley 33, a swash plate 43, a pitch connecting rod 18, an eccentric shaft 4, a periodic pitch slide rail 31, a pitch tappet 30 ...

Embodiment 2

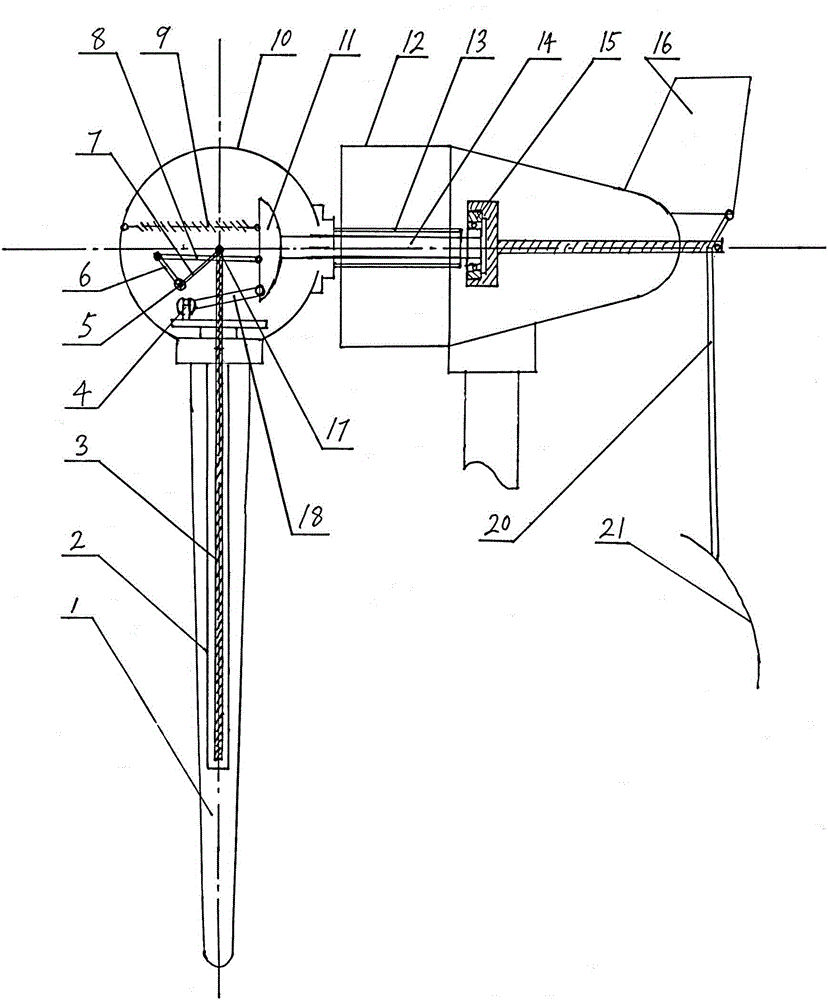

[0021] Such as figure 2 As shown, the centrifugal variable pitch wind power generator in this embodiment includes a blade 1, a generator 12, a generator hollow shaft 13 and a hub 10, and the blade 1 is provided with a centrifugal body slide integrated with the blade. Sleeve 2, the centrifugal body sliding sleeve is hollow tubular, and the centrifugal body 3 is installed in the centrifugal body sliding sleeve. The centrifugal body 3 slides back and forth in the centrifugal body sliding sleeve 2. The centrifugal body is a cylinder. The centrifugal body and the paddle The leaves are connected by a lever rocker device. The lever rocker arm device includes a centrifugal body shaft Xiao 17, a lever 7, a lever shaft 5, a rocker arm 6, a connecting rod 8, a synchronous disc 11, a pitch connecting rod 18, an eccentric shaft 4 and a return tension spring 9, The centrifugal body 3 is movably connected to one end of the lever 7 through the centrifugal body shaft Xiao 17, the rocking arm...

Embodiment 3

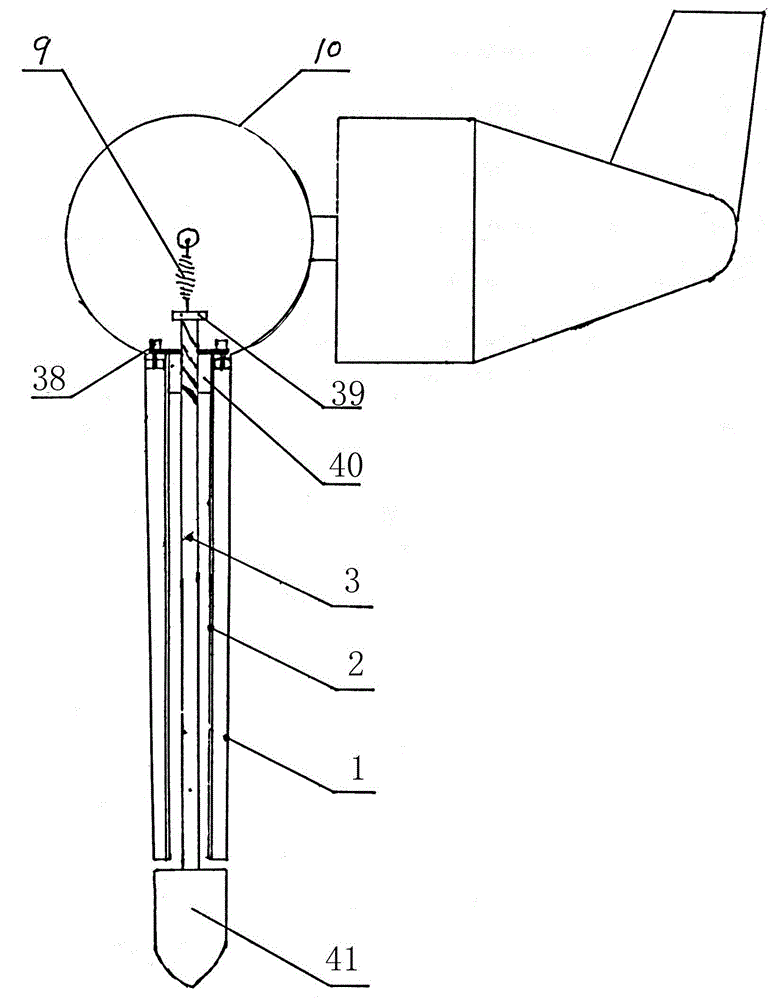

[0024] Such as image 3 As shown, the centrifugal variable pitch wind power generator in this embodiment includes a blade 1 and a hub 10, the blade 1 is provided with a centrifugal body sliding sleeve 2 integrated with the blade, and the centrifugal body sliding sleeve is a hollow tubular Yes, a centrifugal body 3 is installed in the centrifugal body sliding sleeve, and the centrifugal body 3 slides reciprocally in the centrifugal body sliding sleeve 2. The centrifugal body is a cylinder, and the centrifugal body and the paddle are connected by threads. The paddle 1 is fixed on the paddle hub 10 by screws 38, and the paddle 1 is a fixed-pitch blade. A nut 40 is arranged in the blade end, and the centrifugal body 3 is positioned at the middle part of the blade, and one end of the centrifugal body 3 is connected with the blade tip 41, and the other end of the centrifugal body is connected with the spacer 39 after passing through the nut 40, and the centrifugal body and the The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com