Buffer capable of automatically sucking and releasing sliding block

A technology of buffers and first-stage buffers, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of sliding block rebound and piston not working in time, and achieve long life and wide application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

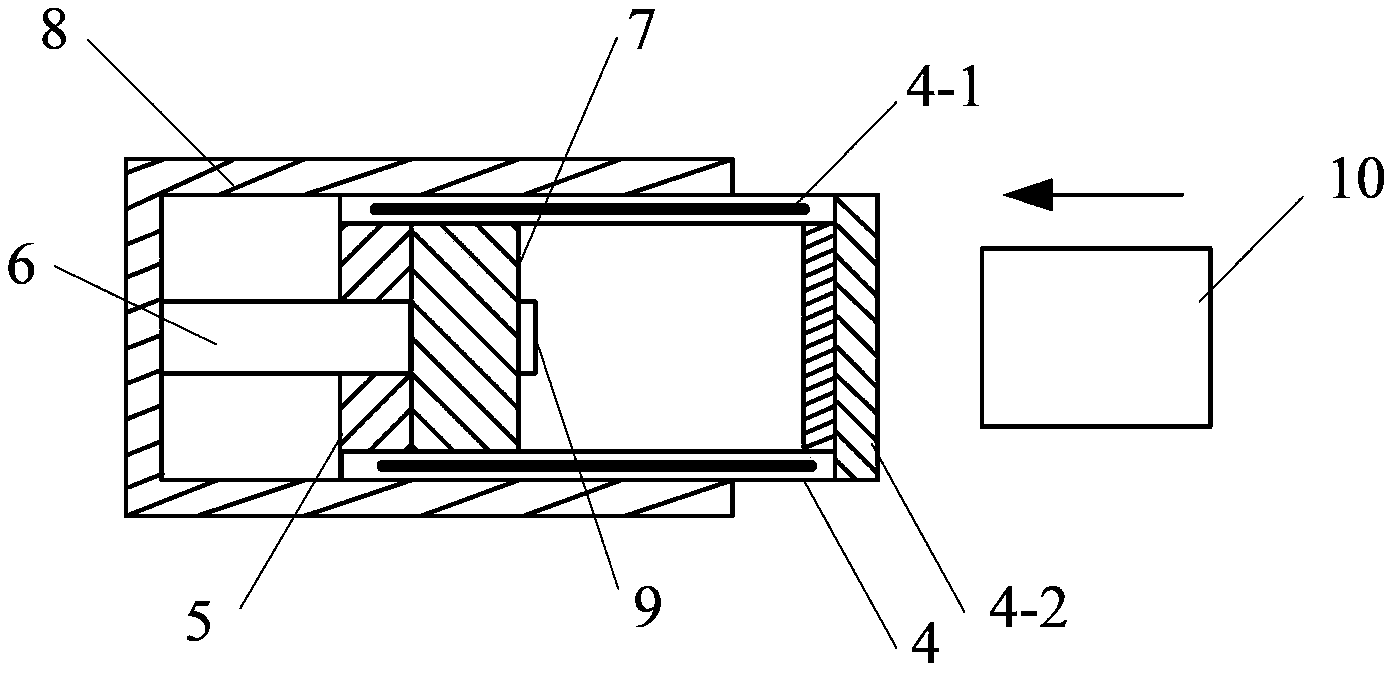

[0020] See figure 1 and Figure 6 , a buffer that automatically attracts and releases a slider, including: a cylinder 4 that is cylindrical and used to fill a buffer medium, and a cylinder cover 5 is sealed at the open end of the cylinder 4, and the cylinder cover In the central through hole of 5, there is a piston rod 6 for sealing activity, and the right end of the piston rod 6 is provided with a piston body assembly 7, and the piston body assembly 7 is suitable for piston movement in the cylinder body 4; during buffering work, The right end face of described cylinder body 4 is used as the contact surface that collides with slide block 10, and the buffer layer 4-2 that is used to buffer slide block 10 impact is laid on this right end face, and this slide block 10 is magnetic slide block; An electromagnetic coil 4-1 is wound around the side wall of the body 4, and a pressure sensor 9 for detecting medium pressure is provided on the right end surface of the piston body assemb...

Embodiment 2

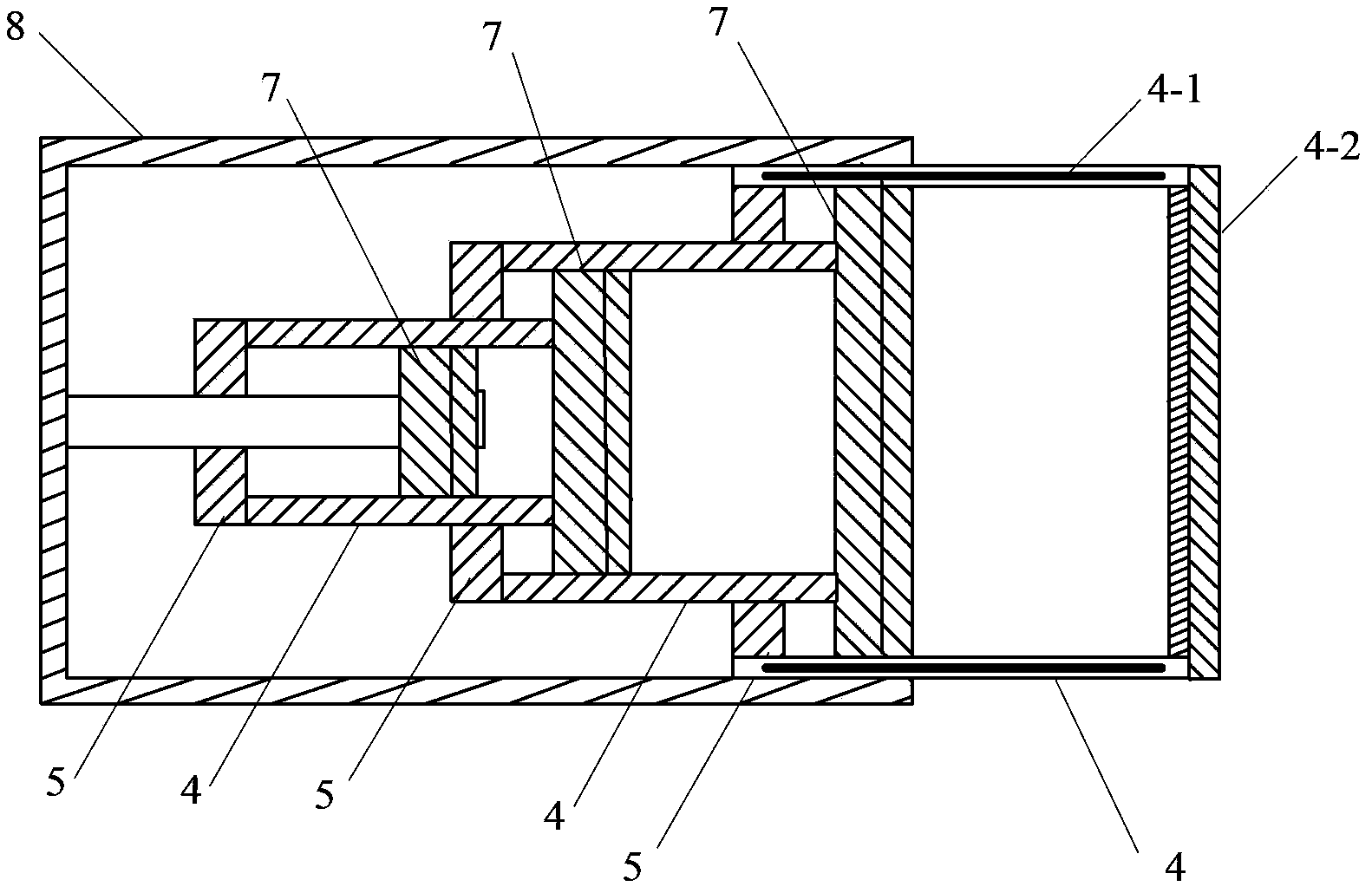

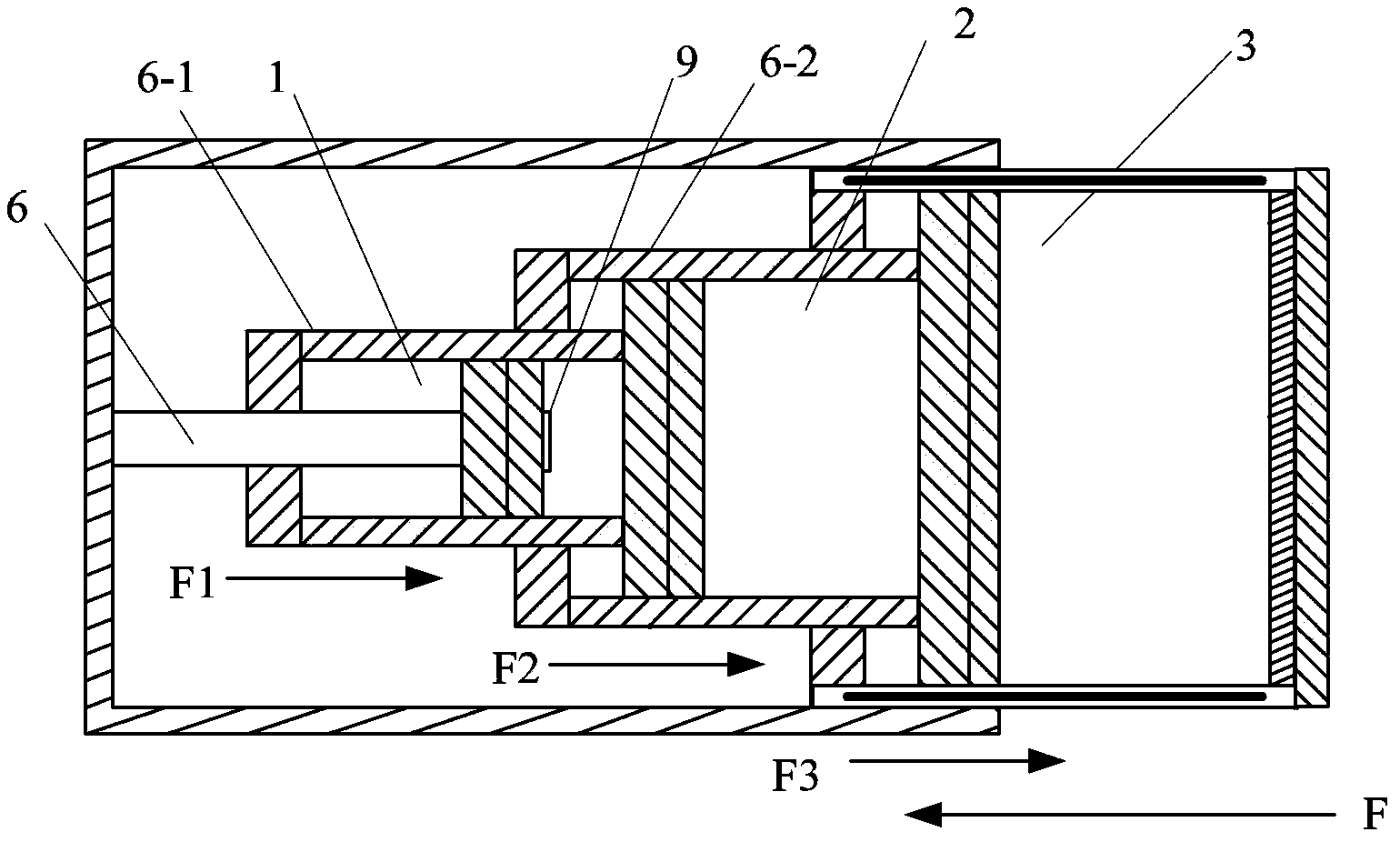

[0026] See figure 2 and image 3 , the buffer is a three-stage buffer, including: a first-stage buffer 1, an intermediate-stage buffer 2 and a final-stage buffer 3; the first-stage buffer 1, the intermediate-stage buffer, and the final-stage buffer 3 are respectively It includes: a cylinder body 4 that is cylindrical and used to fill with a buffer medium. A cylinder head 5 is sealed at the opening end of the cylinder body 4, and a piston rod 6 is sealed and movably fitted in the central through hole of the cylinder head 5. The right end of the piston rod 6 is provided with a piston body assembly 7, the piston body assembly 7 is suitable for piston movement in the cylinder body 4, and is movable and sealed with the inner wall of the cylinder body 4; wherein the first stage The cylinder 4 of the buffer 1 constitutes the piston rod 6-1 of the intermediate buffer 2, and the cylinder 4 of the intermediate buffer 2 constitutes the piston rod 6-2 of the final buffer 3; When workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com