Embedded slag type structure of heating element electrodes of electromagnetic induction slag smelting furnace

An electromagnetic induction and induction heating technology, which is applied in the direction of electric furnace heating, furnace, furnace components, etc., can solve the problems of low investment and difficulty in guaranteeing the quality of slag cotton, achieve high power factor, solve oxidation burning loss, and have obvious cost advantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

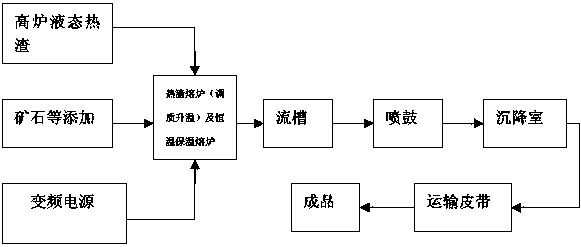

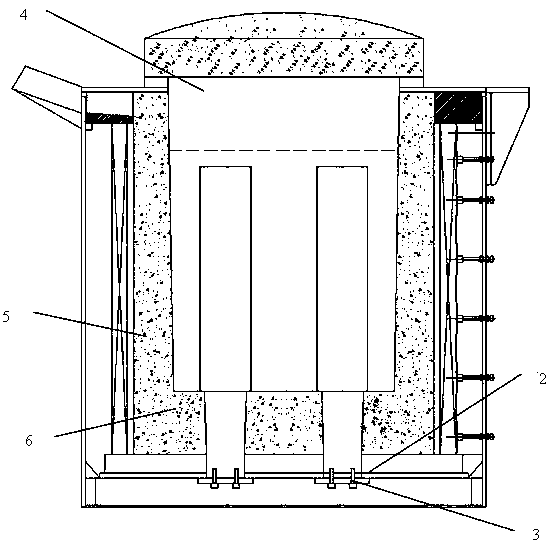

[0036] Embodiment, the melting and tempering hot slag melting furnace consists of a furnace transport trolley, an electromagnetic induction furnace body (3t---60t), a frequency conversion power supply (1000---20000kw), a liftable and rotatable furnace cover, a liftable and rotatable Induction electrode, calculator, PLC control system, etc.;

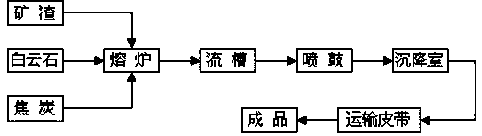

[0037] Short-process mineral wool production, including

[0038] 1) The hot slag of the blast furnace is directly or transferred into the hot slag melting furnace by chartering the car, (the hot slag loading has a remarkable energy-saving effect), and the hot slag of the blast furnace is about 1500 degrees;

[0039] 2) After being loaded into the molten quenched and tempered hot slag furnace, the temperature will drop to about 1200 degrees;

[0040] 3) The temperature is raised to about 1500 degrees through the electromagnetic induction of the melting and tempering hot slag furnace;

[0041] 4) Then add 10% to 20% of quartz stone to 80%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com