Motor vehicle headlamp detector light intensity detection method

A detection method and technology of headlights, which are applied in the direction of testing the alignment of automobile headlights, photometry, and testing optical properties, etc., to achieve the effects of solving brightness loss, high detection accuracy, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

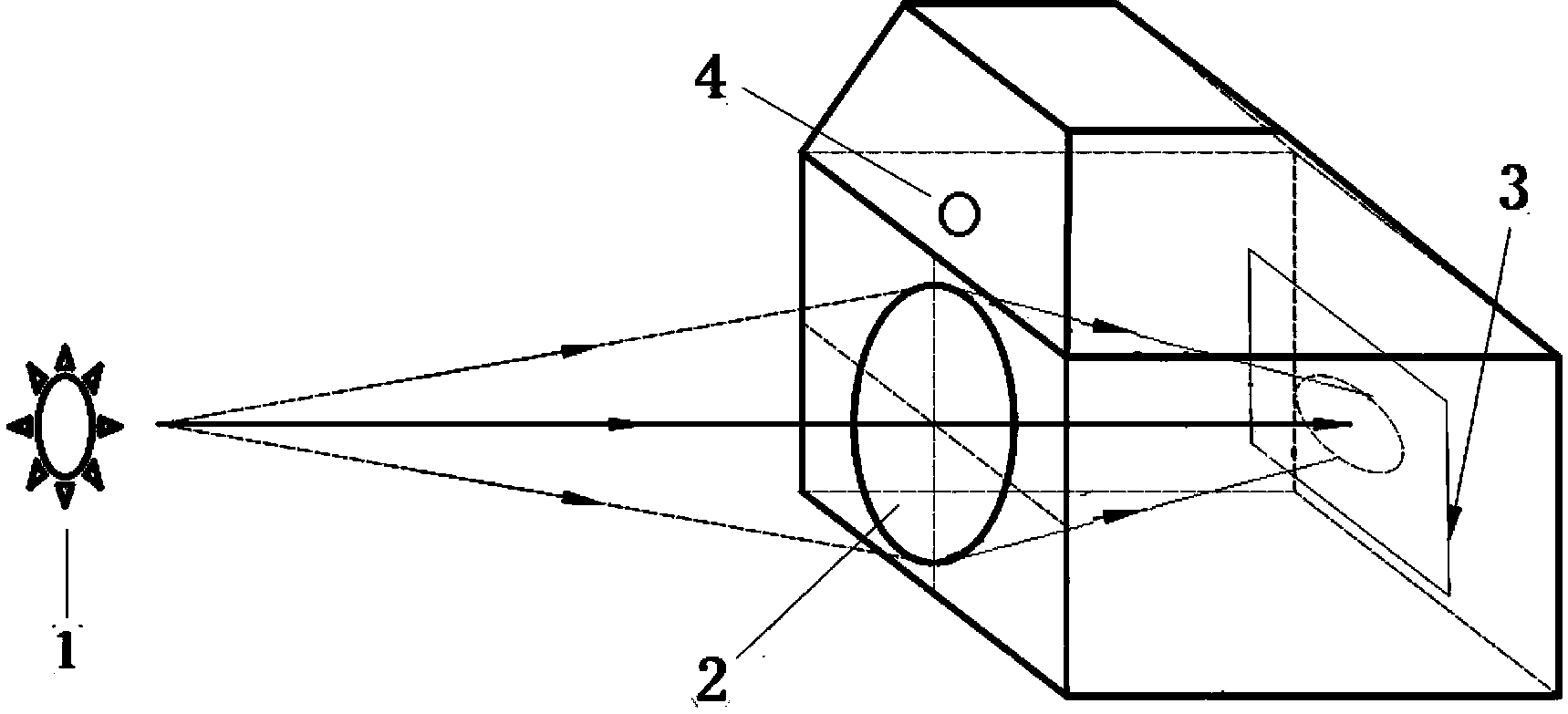

[0037] The light intensity detection method of the motor vehicle headlight detector of the present invention comprises the following steps:

[0038] a. Use the headlamp detector calibrator to calibrate the headlamp detector, set the luminous intensity of the calibrator to a fixed value, and place the optical axis offset angle of the calibrator at different calibration points, Read and record the luminous intensity indication value f(x i ,y i );

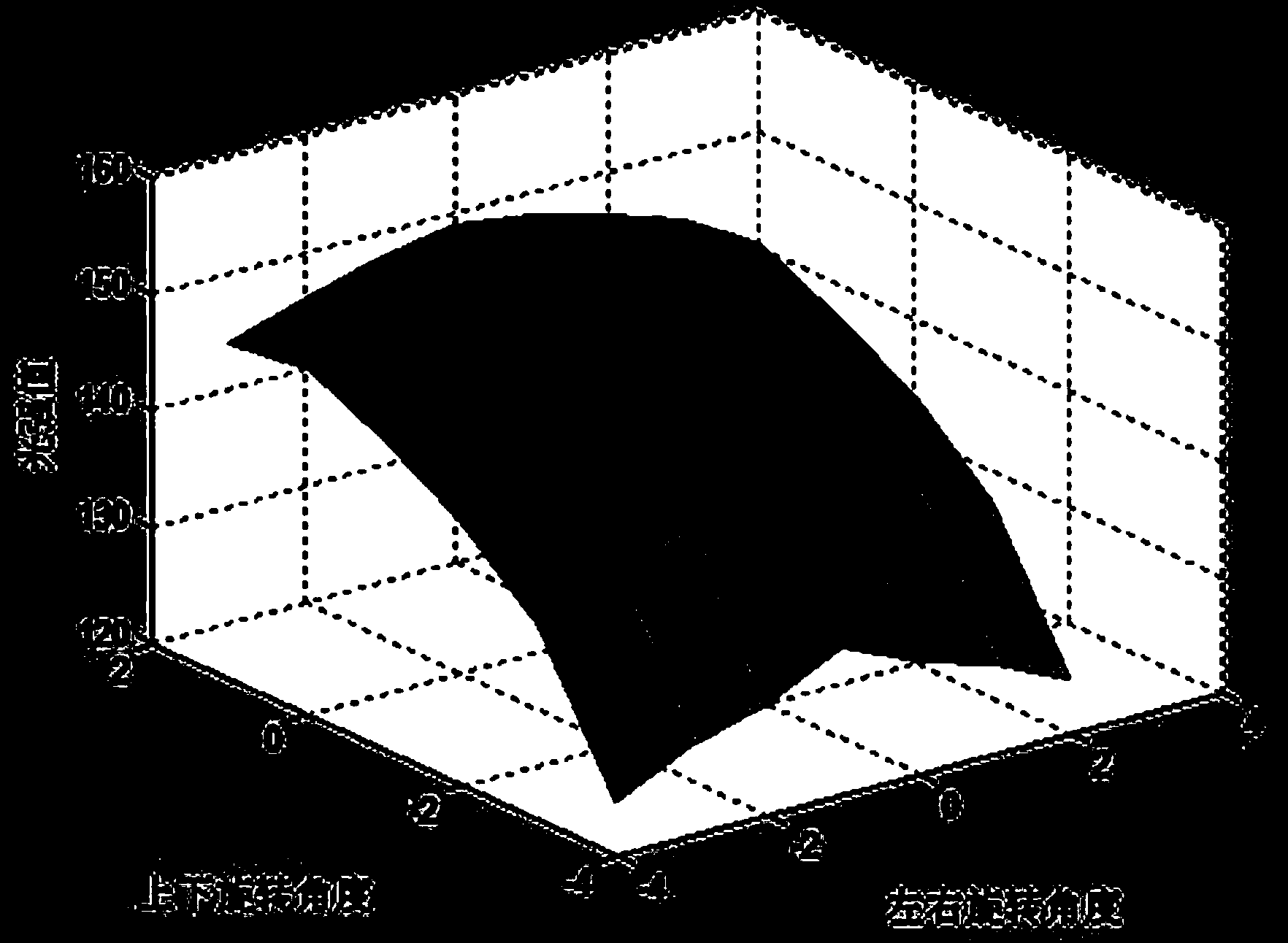

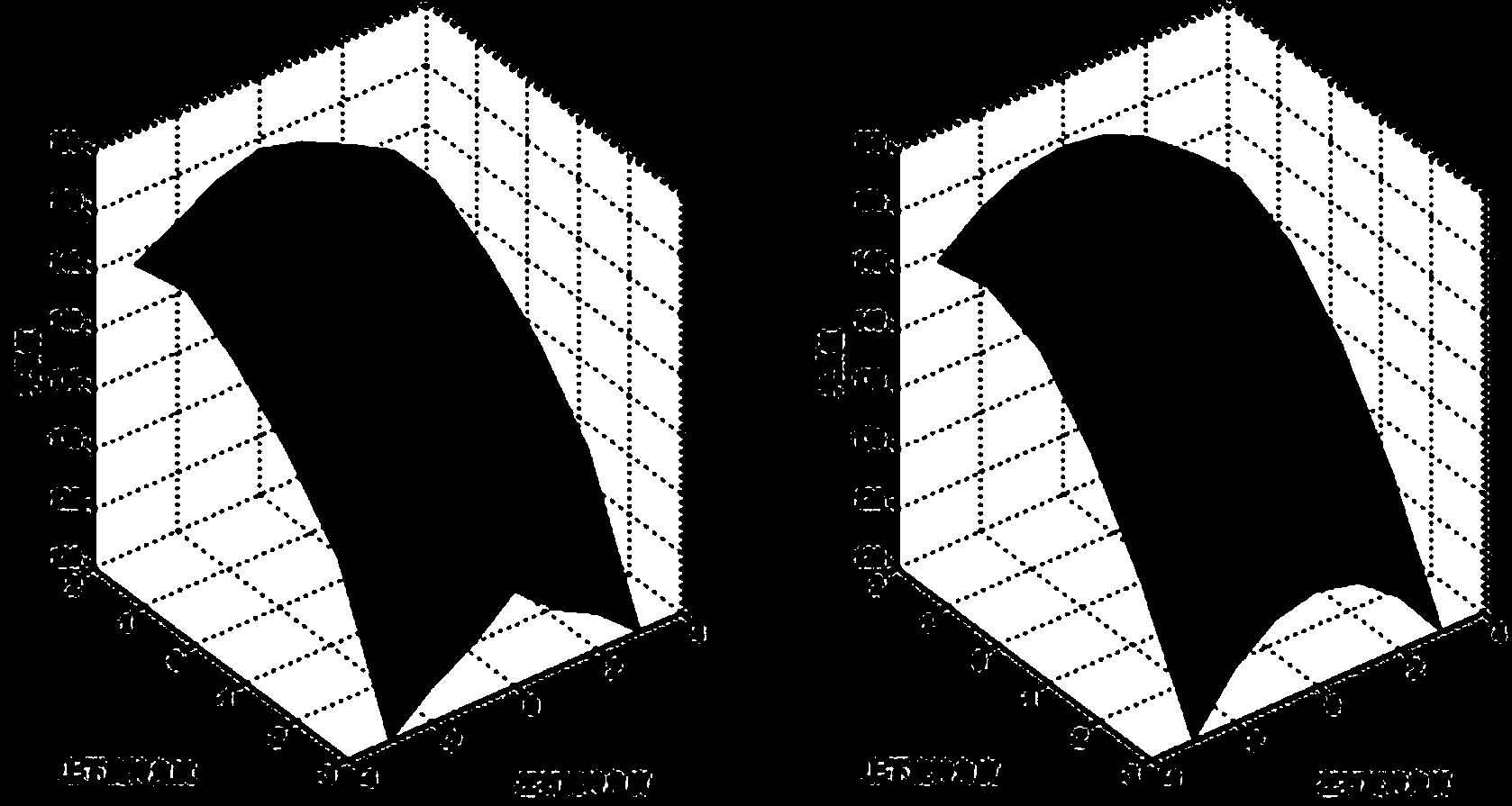

[0039] b. For each luminous intensity value f(x) recorded above i ,y i ) to fit the light intensity surface to obtain the light intensity surface equation;

[0040] c. Using the light intensity surface equation in the above step b, the headlight detector corrects the read luminous intensity indications of the headlight at each offset angle point to obtain the real light intensity value of the headlight.

[0041] Wherein, the verification test points described in the above step a include some reference points as shown in Table 1; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com