Method and apparatus for on-line replacement of annealing kiln drive system

A transmission system and annealing kiln technology, applied in the transmission system field, can solve the problems of long replacement time, long time, and occupation of a lot of labor, and achieve the effects of reducing manpower and labor intensity, improving economic benefits, and shortening replacement time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

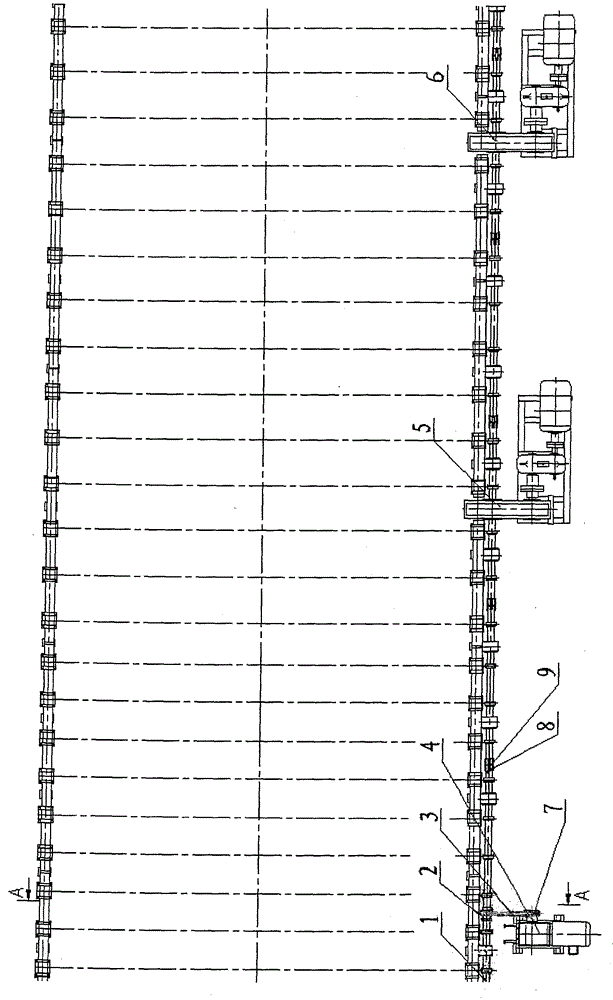

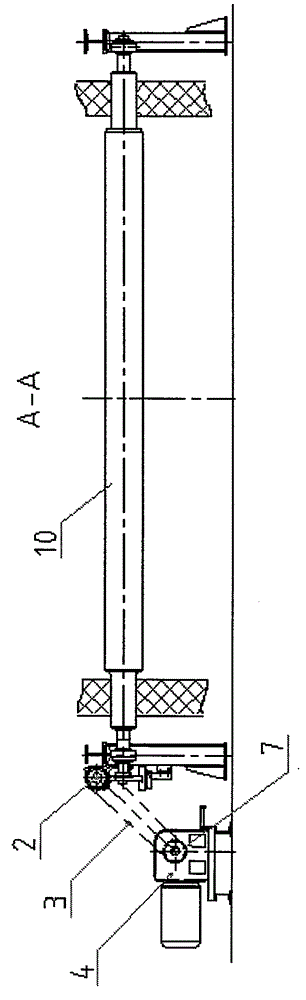

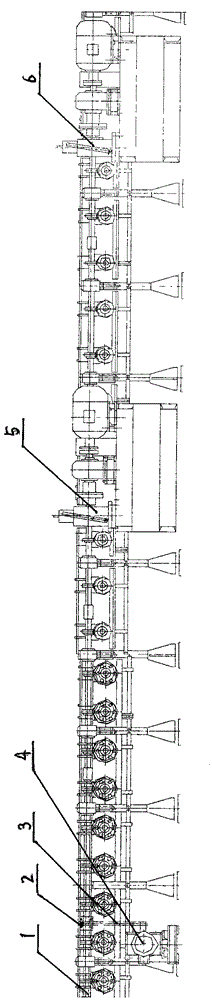

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

[0040] like figure 1 and figure 2 As shown, the transmission system of the annealing kiln includes a main drive device 5, a backup drive device 6, a plurality of conveying rollers 10, and a transmission shaft 1 arranged between the above-mentioned drive device and the conveying rollers 10. When the main drive device 5 fails, the standby drive The device 6 drives the transmission shaft 1 to move, and the original active drive transmission shaft 1 becomes passively driven at this time, so a good opportunity is provided for quickly replacing the faulty main drive device 5 at this time. For this reason, the invention provides a device for online replacement of the transmission system of an annealing kiln. Using this invention, the rapid replacement of the faulty drive device can be realized in this short time. The structure diagram of the invention is as follows image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com