Construction method of cast-in-site planting concrete revetment

A technology of greening concrete and construction methods, which can be applied to botanical equipment and methods, excavation, coastline protection, etc. It can solve the problems of low flexural strength of concrete blocks, excessively large holes, and not resistant to water erosion, etc., and achieve effective It is beneficial to water and soil protection, beneficial to plant growth, and the effect of reducing high temperature damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be described in detail below in conjunction with specific examples, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention.

[0029] Unless otherwise specified, the technical means used in the examples are conventional means well known to those skilled in the art, and the reagents and products used are also commercially available. The sources, trade names and, where necessary, listing of constituents of reagents used are indicated the first time they appear.

[0030] Embodiments of the invention are:

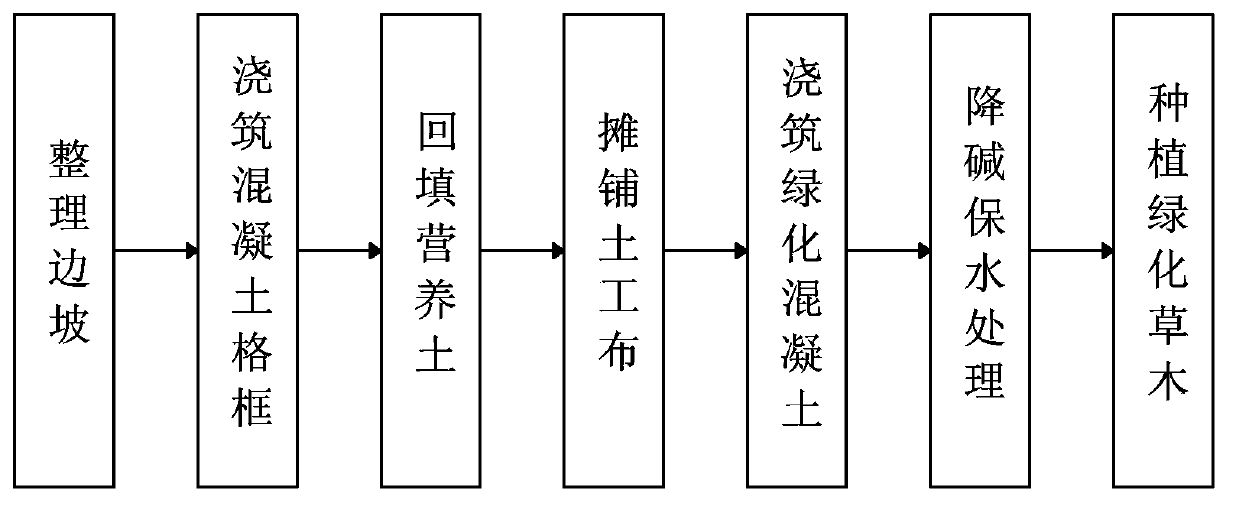

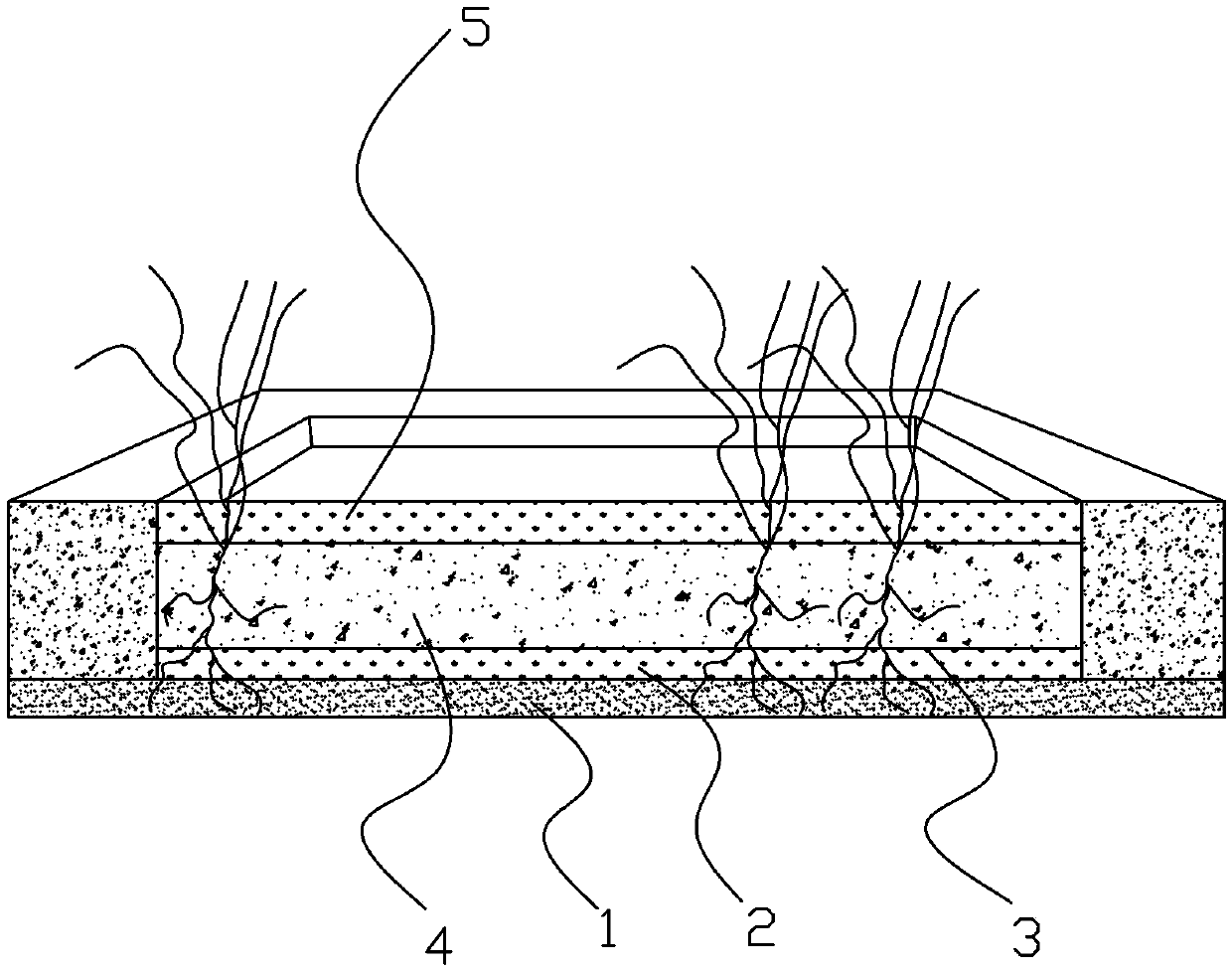

[0031] refer to figure 1 , a construction method of cast-in-situ greening concrete slope protection, comprising the following steps:

[0032] 1) Prefabricated acidic nutrient soil: take 4 parts by weight of crop residues such as chaff and bran or organic tissues such as distiller's grains and biogas residues...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com