Steel wire belt hot gluing method

A technology with heat and gluing, applied in the direction of belt fasteners, belts/chains/gears, machinery and equipment, etc., can solve the problems of quality problems and complex hot gluing process, so as to prolong the service life and shorten the maintenance work. time, the effect of ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

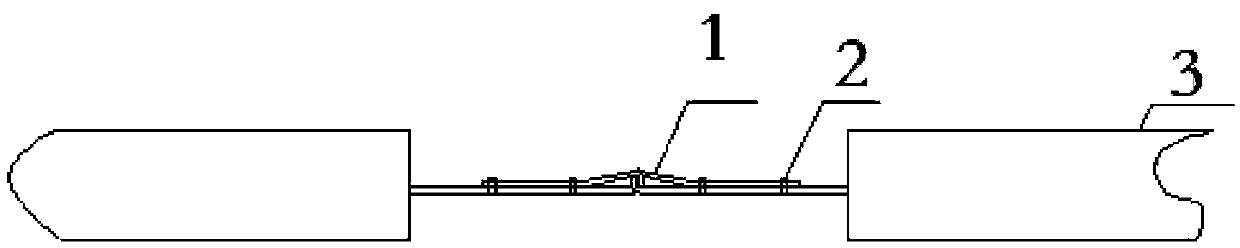

[0036] The present example will be described below in conjunction with the embodiments and the accompanying drawings.

[0037] The invention further optimizes the bonding process of steel wire ropes, effectively overcomes the disadvantages of the prior art such as complex process, prone to scratches, joint deformation, and low bonding strength, greatly shortens the time for on-site maintenance operations, and effectively Improve the bonding strength of the belt.

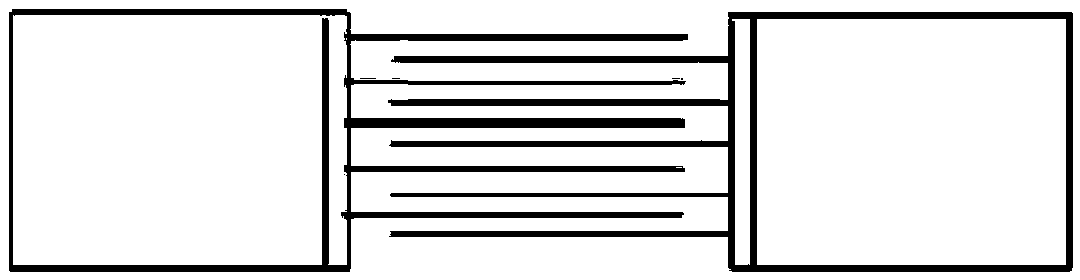

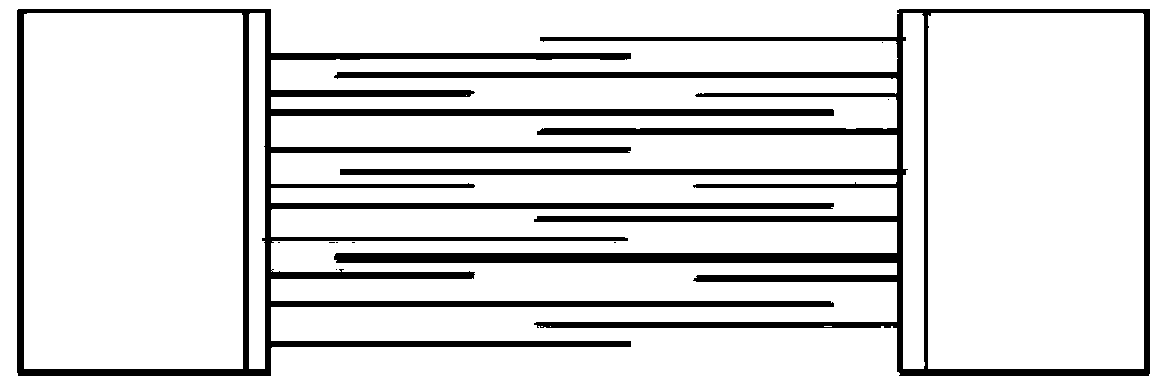

[0038] In the embodiment, the first-level lapping method of the belt comprises:

[0039] Picking the head of the belt: When picking the head, first cut off the rubber layer on both sides of the belt until the first steel wire rope leaks out, then cut the steel wire rope at an angle of 45° up and down, and take out the wire rope after cutting through. By analogy, the steel wire ropes are taken out in sequence, and this operation can also be performed on both sides of the belt at the same time. Do not pull out the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com