Cobalt molybdate/carbon composite nanosphere, preparation method and application as electrode material

A nanosphere and carbon composite technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of unfavorable energy density of supercapacitors, reduce the quality of active materials, and poor conductivity of electrode materials, etc., and achieve simple operation process Environmental protection, process safety, high conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) preparation concentration is the cobalt chloride aqueous solution of 0.03mol / L, the sodium molybdate aqueous solution of preparation 0.04mol / L;

[0030] 2) Mix cobalt chloride aqueous solution and sodium molybdate aqueous solution with a volume ratio of 1:3, ultrasonicate for 10 minutes, and stir for 10 hours. After the reaction is completed, product A is obtained by suction filtration, washing and drying;

[0031] 3) ultrasonically disperse 30 mg of product A in 150 mL of 2-hydroxyacetanilide aqueous solution with a concentration of 0.03 mol / L, stir at room temperature for 10 h, filter, wash, and dry to obtain product B;

[0032] 4) Calcining the product B at 600° C. for 2 h under a nitrogen atmosphere to obtain cobalt molybdate-carbon composite nanospheres.

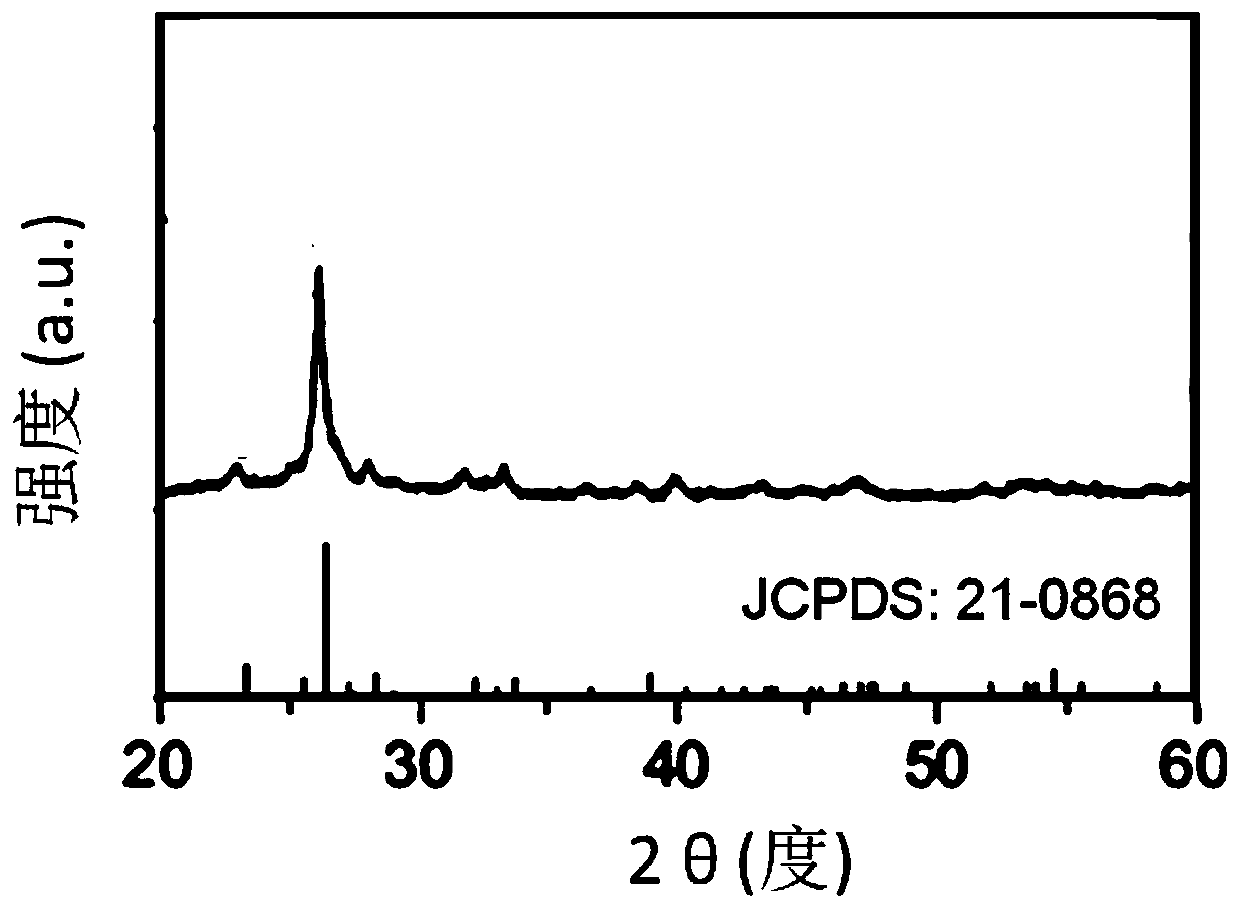

[0033] see figure 1 , figure 1 The scanning electron microscope picture of the cobalt molybdate-carbon composite nanosphere prepared for the present invention; it can be seen from the picture that the spheri...

Embodiment 2

[0037] 1) preparation concentration is the cobalt nitrate aqueous solution of 0.01mol / L, the ammonium molybdate aqueous solution of preparation 0.02mol / L;

[0038] 2) Mix cobalt nitrate aqueous solution and ammonium molybdate aqueous solution with a volume ratio of 1:1, and ultrasonicate for 5 minutes, then stir for 7 hours. After the reaction is completed, filter, wash, and dry to obtain a cobalt molybdate intermediate, which is designated as product A;

[0039] 3) ultrasonically disperse 20 mg of product A in 100 mL of 3-(dibutylamino)phenol aqueous solution with a concentration of 0.01 mol / L, stir at room temperature for 7 hours, filter, wash and dry to obtain product B;

[0040] 4) Calcining the product B at 400° C. for 2 h under an argon atmosphere to obtain cobalt molybdate-carbon composite nanospheres.

Embodiment 3

[0042] 1) preparation concentration is the cobalt acetate aqueous solution of 0.02mol / L, the sodium molybdate aqueous solution of preparation 0.03mol / L;

[0043]2) Sonicate the cobalt acetate aqueous solution and sodium molybdate aqueous solution with a volume ratio of 1:2 for 7 minutes, and then stir for 9 hours. After the reaction is completed, the product A is obtained by suction filtration, washing and drying;

[0044] 3) Ultrasonic disperse 20 mg of product A in 100 mL of 4-(2-aminoethyl)-1,2-benzenediol aqueous solution with a concentration of 0.02 mol / L, stir for 9 hours at normal temperature and pressure, filter and wash , obtain product B after drying;

[0045] 4) Calcining the product B at 500° C. for 2 h under an argon atmosphere to obtain cobalt molybdate-carbon composite nanospheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com