Cassava drying machine

A drying machine and cassava technology, which is applied in the direction of drying machine, drying, local stirring dryer, etc., can solve the problems of material zooming, long production cycle, and easy mold and deterioration of products, so as to reduce the loss of heat energy and reduce heat energy Loss, better drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

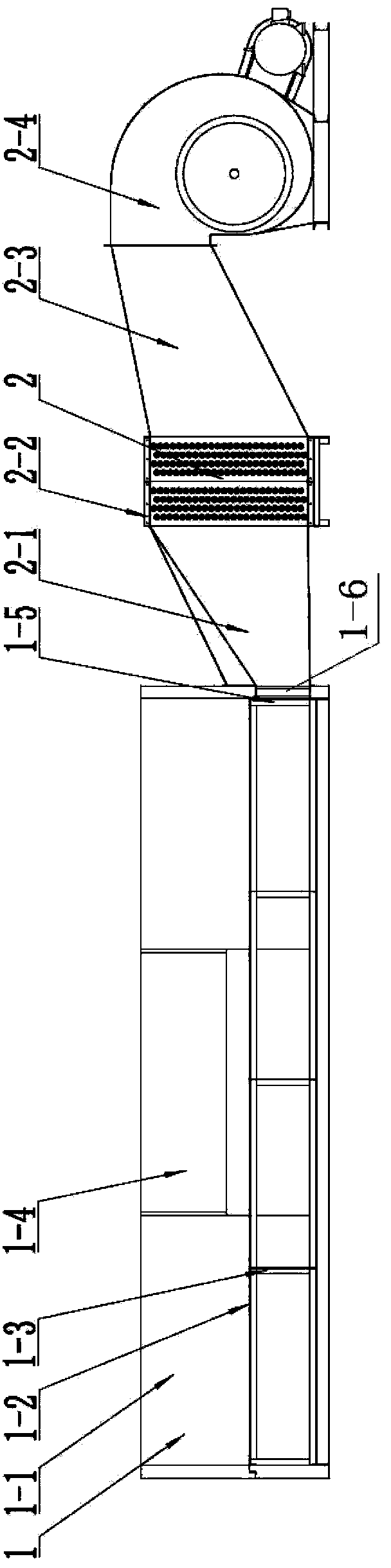

[0020] Such as figure 1 As shown, it is a cassava dryer of the present invention, comprising a drying box 1 and a hot air system 2, the drying box 1 is a trough-type box without a cover, and consists of a thermal insulation wall plate 1-1, a discharge port 1 -4. Consisting of material bearing orifice plate 1-2, bearing frame 1-3, reserved air inlet 1-6 and deflector 1-5. A material receiving orifice plate 1-2 supported by a load-bearing frame 1-3 is arranged in the drying box 1, and the box wall plate 1-1 of the drying box 1 is provided with an outlet that is located above the material receiving orifice plate 1-2. Material openings 1-4 and reserved air inlets 1-6 are arranged on the front side of the drying box 1, and deflectors 1-5 are installed on the reserved air inlets; the hot air system 2 consists of heat exchange devices 2-2 and fans 2 -4 structure, the heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com