Multi-optical-axis consistency detection device and method of platform photoelectric device at any axial distance

A multi-optical axis, consistent technology, used in measuring devices, optical devices, instruments, etc., can solve the problems of large size, high environmental requirements and heavy weight of detection devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Embodiment 1: An arbitrary wheelbase multi-optical axis consistency detection device for platform optoelectronic equipment.

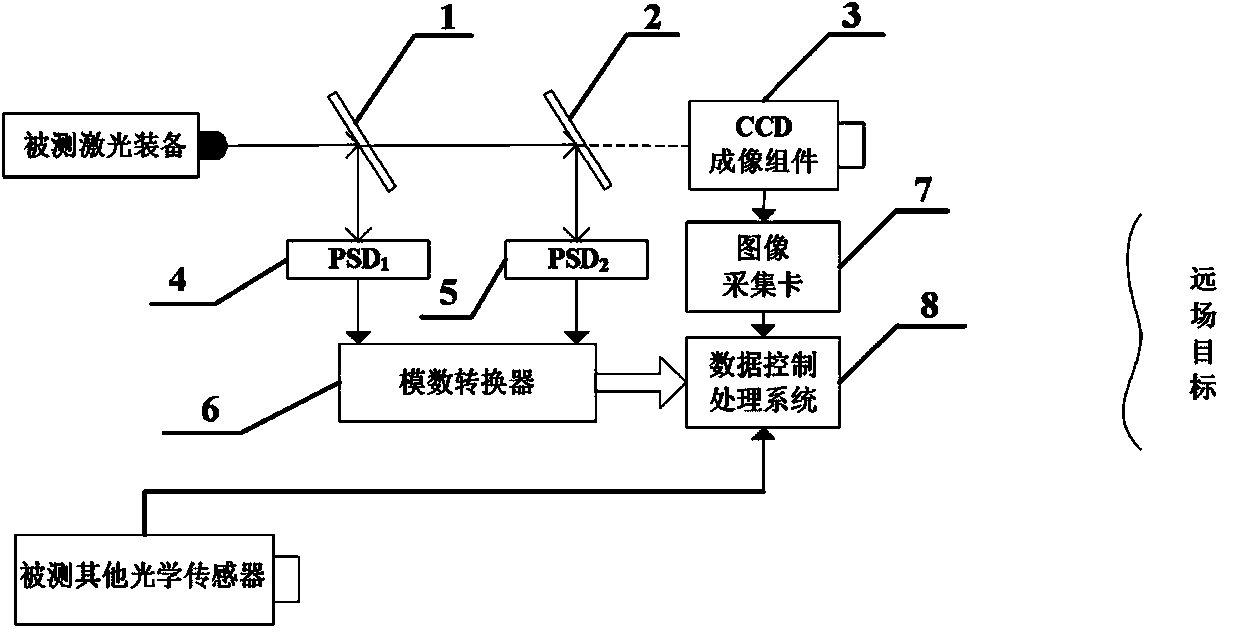

[0089] Such as figure 1 As shown, the arbitrary wheelbase multi-optical axis consistency detection device of the platform optoelectronic equipment provided by the present invention includes a half mirror 1, a mirror 2, a CCD imaging assembly 3, a first position sensitive device 4, a second position sensitive Device 5 , analog-to-digital converter 6 , image acquisition card 7 and data control processing system 8 . The Position Sensitive Detector (PSD) here, also known as "position sensitive detector", is an optical device that measures the spot position according to the optical signal.

[0090] The half-mirror 1 is used to reflect and transmit the laser emitted by the laser equipment under test. The reflected laser beam directly enters the first position sensitive device 4 , and the transmitted laser beam directs to the reflector 2 as the inciden...

Embodiment 2

[0098] Embodiment 2: A method for detecting the consistency of multiple optical axes with any wheelbase of the optoelectronic equipment of the platform.

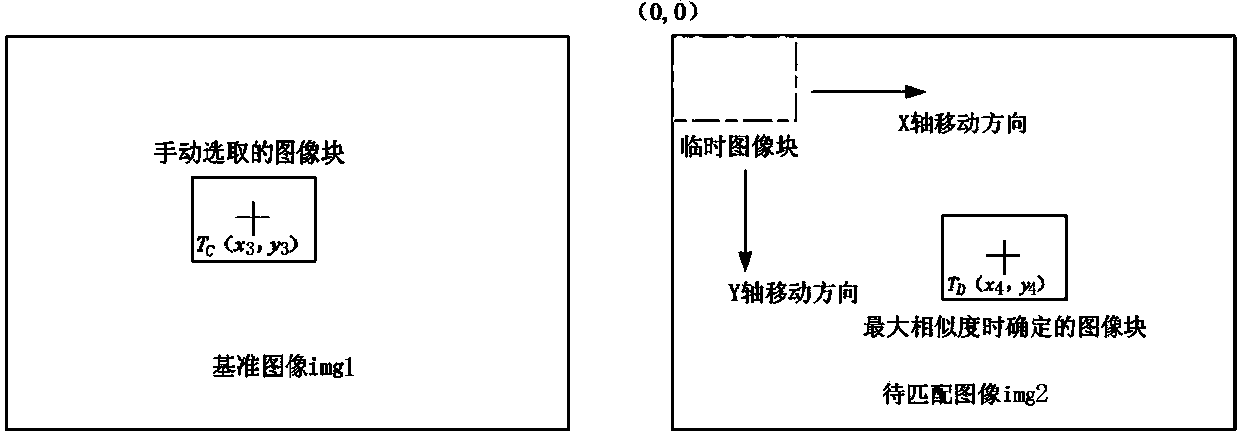

[0099] The detection method is based on position sensitive devices, non-cooperative targets and image processing technology, and the specific steps are as follows:

[0100] refer to figure 1 , it is assumed that the optoelectronic equipment of the tested platform in the present invention includes laser equipment, visible light (including low light) sensors and infrared sensors.

[0101] Firstly, the optoelectronic equipment of the tested platform is aimed at a fixed non-cooperative target at the infinite field of view, and the detection device is placed in front of the laser emission window of the tested laser equipment. Adjust the CCD imaging assembly 3 in the detection device to make it aim at the fixed target in the distant scene, adjust the first position sensitive device 4 and the second position sensitive device 5 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com