A kind of running-in test method of hydraulic automatic transmission

A technology of automatic transmission and test method, applied in the direction of machine gear/transmission mechanism testing, etc., can solve problems such as damage to the tested hydraulic automatic transmission, achieve the effects of reducing the probability of damage, improving strength, and prolonging the running-in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

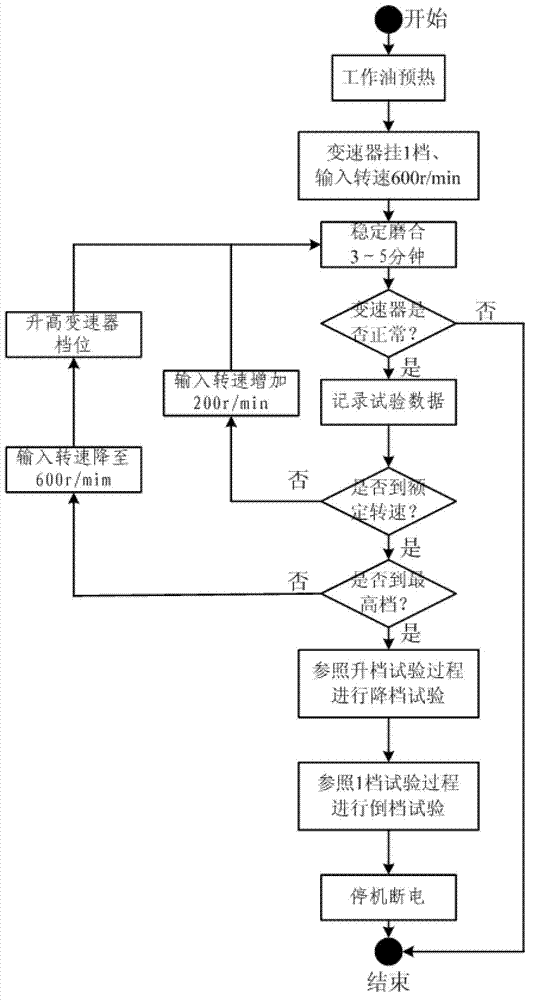

[0018] The technical solutions of the present invention will be further specifically described below in conjunction with the accompanying drawings and specific embodiments.

[0019] The embodiment of the present invention provides a hydraulic automatic transmission running-in test method. The hydraulic automatic transmission used for the test is used for a heavy-duty truck. It has 6 forward gears and a maximum speed of 2000r / min. , the matching engine is a 400-horsepower diesel engine with an idle speed of 600r / min and a maximum speed of 2000r / min. The running-in test is carried out on the hydraulic automatic transmission test bench, such as figure 1 Shown flow chart, comprises the following steps:

[0020] Use the hydraulic oil automatic filling / draining system including the oil storage tank and the oil filling / draining device recorded in the patent application 201220620187.1 to fill the hydraulic automatic transmission with working oil, and make the working oil full of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com