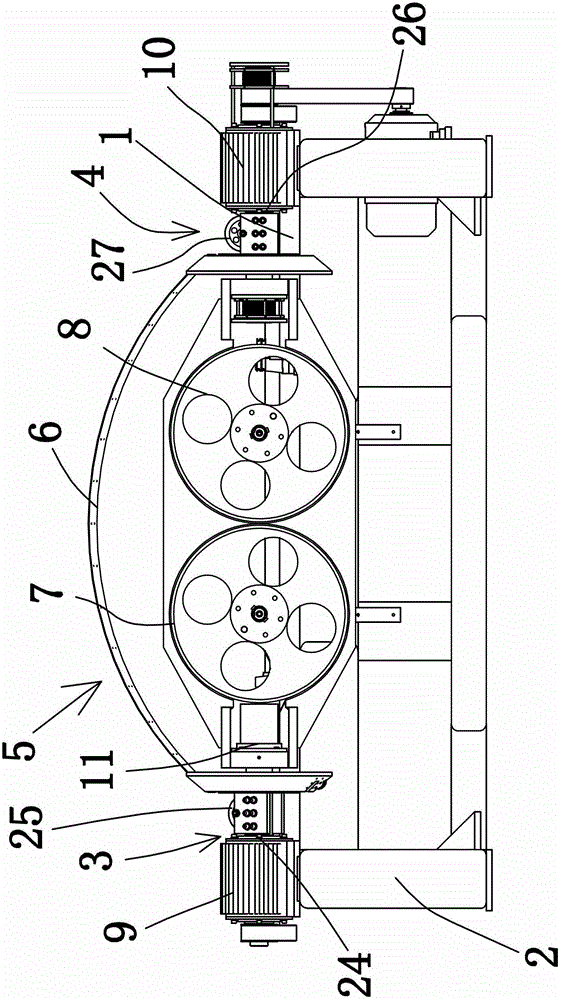

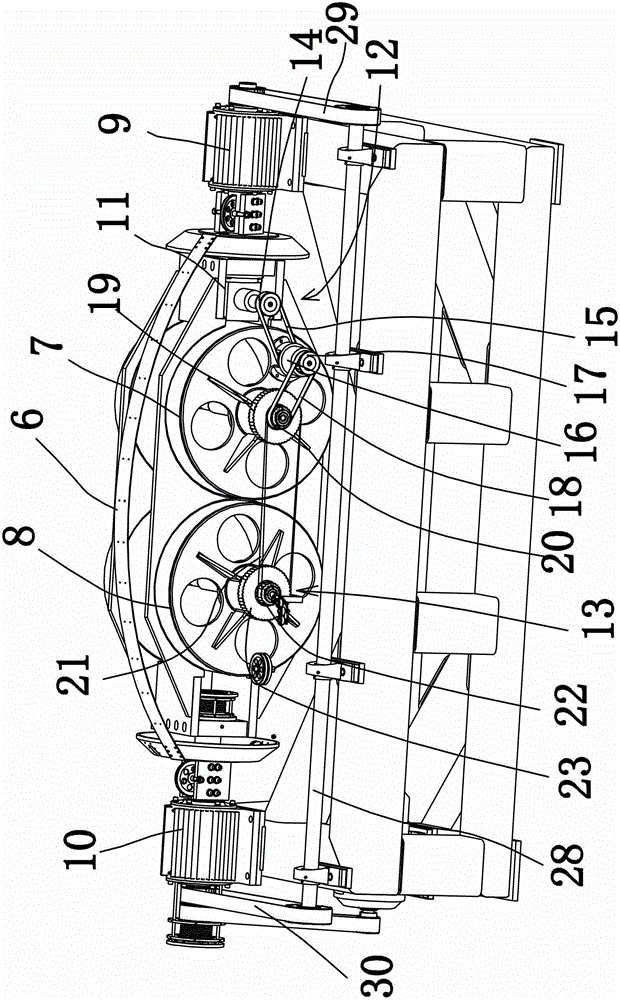

An Improved Structure of the Pay-off Assembly of a Twisting Machine

A pairing machine and assembly technology, applied in the field of machinery, can solve the problems of difficulty in ensuring the synchronization of pay-off, poor stability, cable damage, etc., and achieve the effect of improving work efficiency, good stability and saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

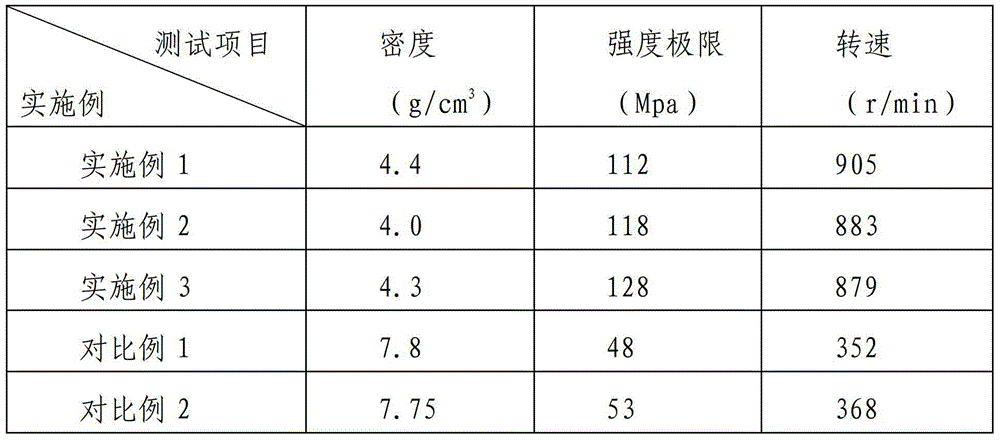

Embodiment 1

[0029]The twisted bow 6 is made of materials in the following molar ratios:

[0030] Al: 20%, Ti: 10%, Cu: 6%, graphite: 3%, and the balance is Fe.

[0031] The preparation method will not be described in detail.

Embodiment 2

[0033] The twisted bow 6 is made of materials in the following molar ratios:

[0034] Al: 23%, Ti: 10%, Cu: 10%, graphite: 5%, and the balance is Fe.

[0035] The preparation method will not be described in detail.

Embodiment 3

[0037] The twisted bow 6 is made of materials in the following molar ratios:

[0038] Al: 25%, Ti: 12%, Cu: 12%, graphite: 5%, and the balance is Fe.

[0039] The preparation method will not be described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com