Synchronous belt type cold rolling forming machine and cold rolling pipemaking machine

A technology of forming machine and synchronous belt, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve problems such as large workload, and achieve the effect of reducing cost and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

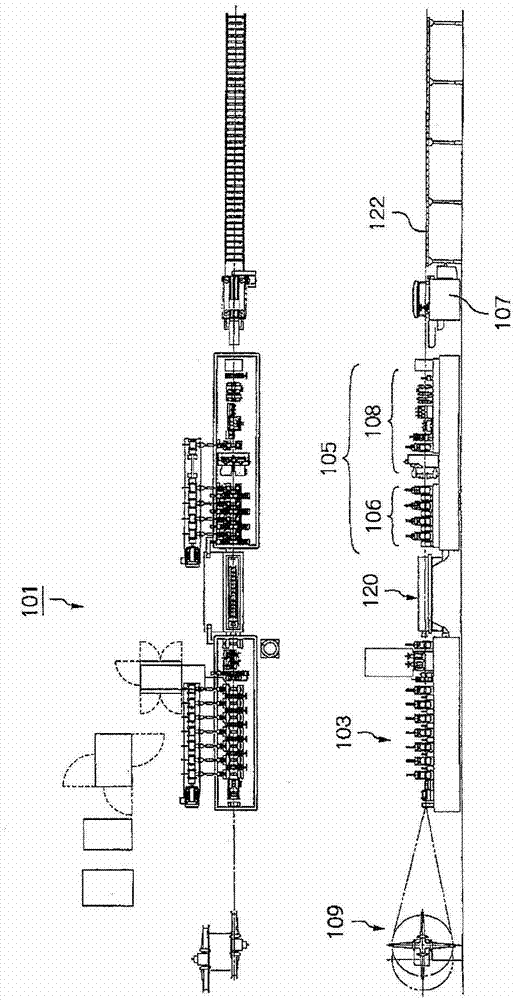

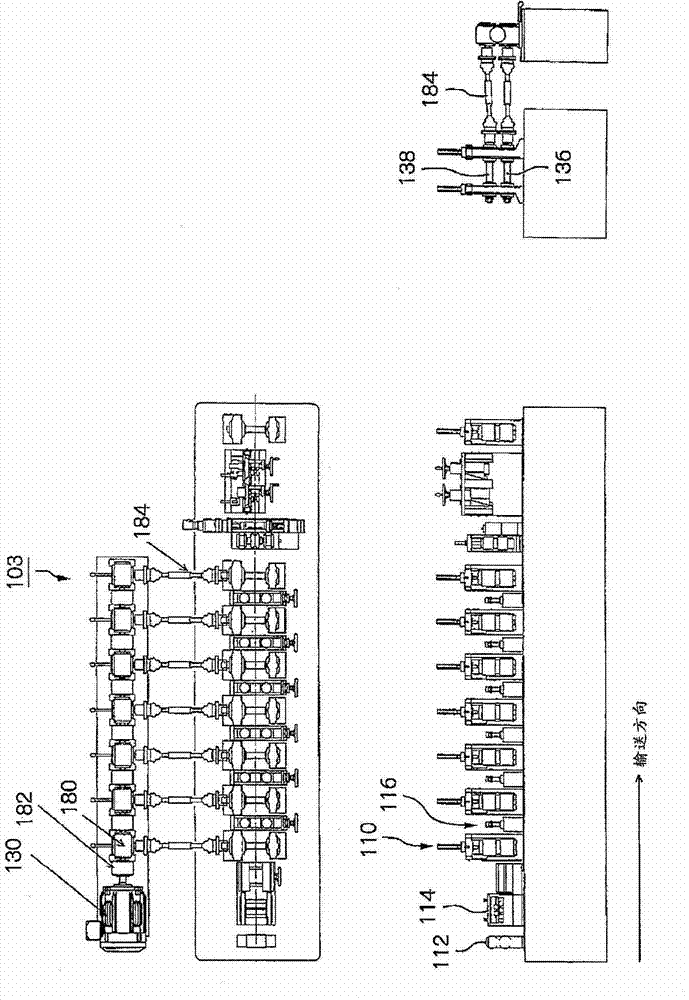

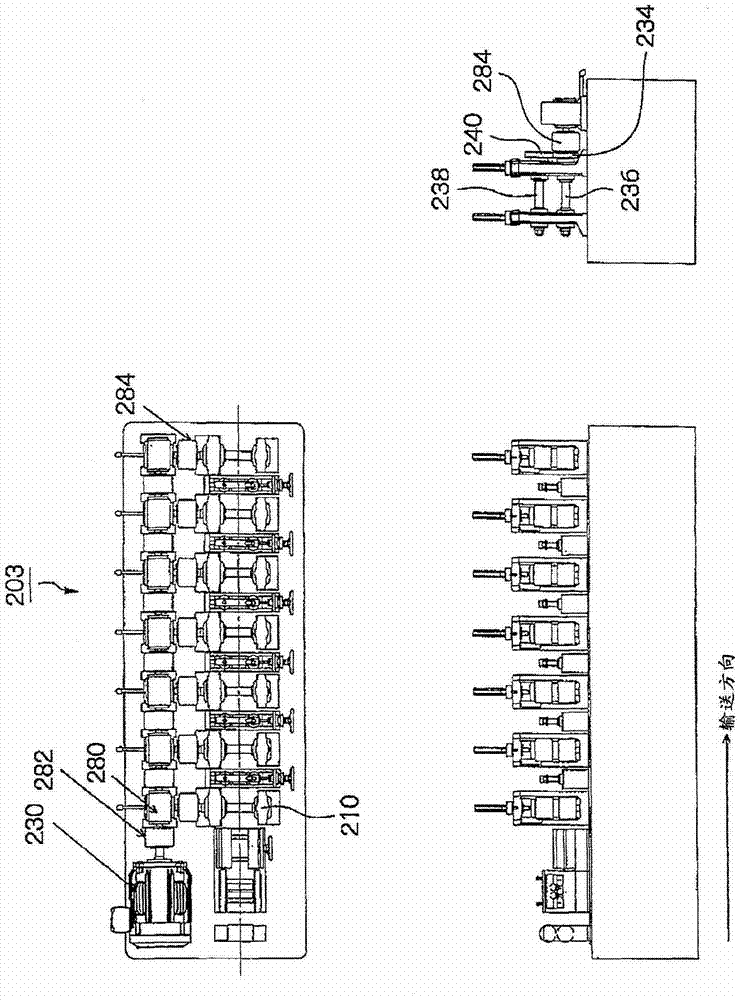

[0040] Hereinafter, modes for implementing the present invention will be described with reference to the drawings. Figure 4 It is an overall view of a cold rolling tube mill 1 as an example of the cold rolling forming machine of the first embodiment, Figure 5 is extracted Figure 4 A view of a part of the forming section 3 of the cold rolling tube mill 1 shown. Such as Figure 5 As shown, in the first embodiment, the forming unit 3 includes seven roll forming stands 10 and six side roll stands 16 as an example of a stand mechanism.

[0041] Composition of cold rolling tube machine

[0042] Figure 4 The shown cold rolling pipe machine 1 is configured to have: a forming part 3 for forming a billet into a predetermined shape; a cooling table 20 as an example of a cooling part for cooling the formed billet through water; Correction unit 5; mobile cutting machine 7. The forming part 3 has a welding part 4 for welding a butt part of a tubular blank. The straightening unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com