Polishing robot

A technology of a robot and a grinding mechanism, applied in the field of robots, can solve the problems of workpiece damage, high labor intensity, low grinding efficiency, etc., and achieve the effect of prolonging the service life, improving the grinding efficiency, and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

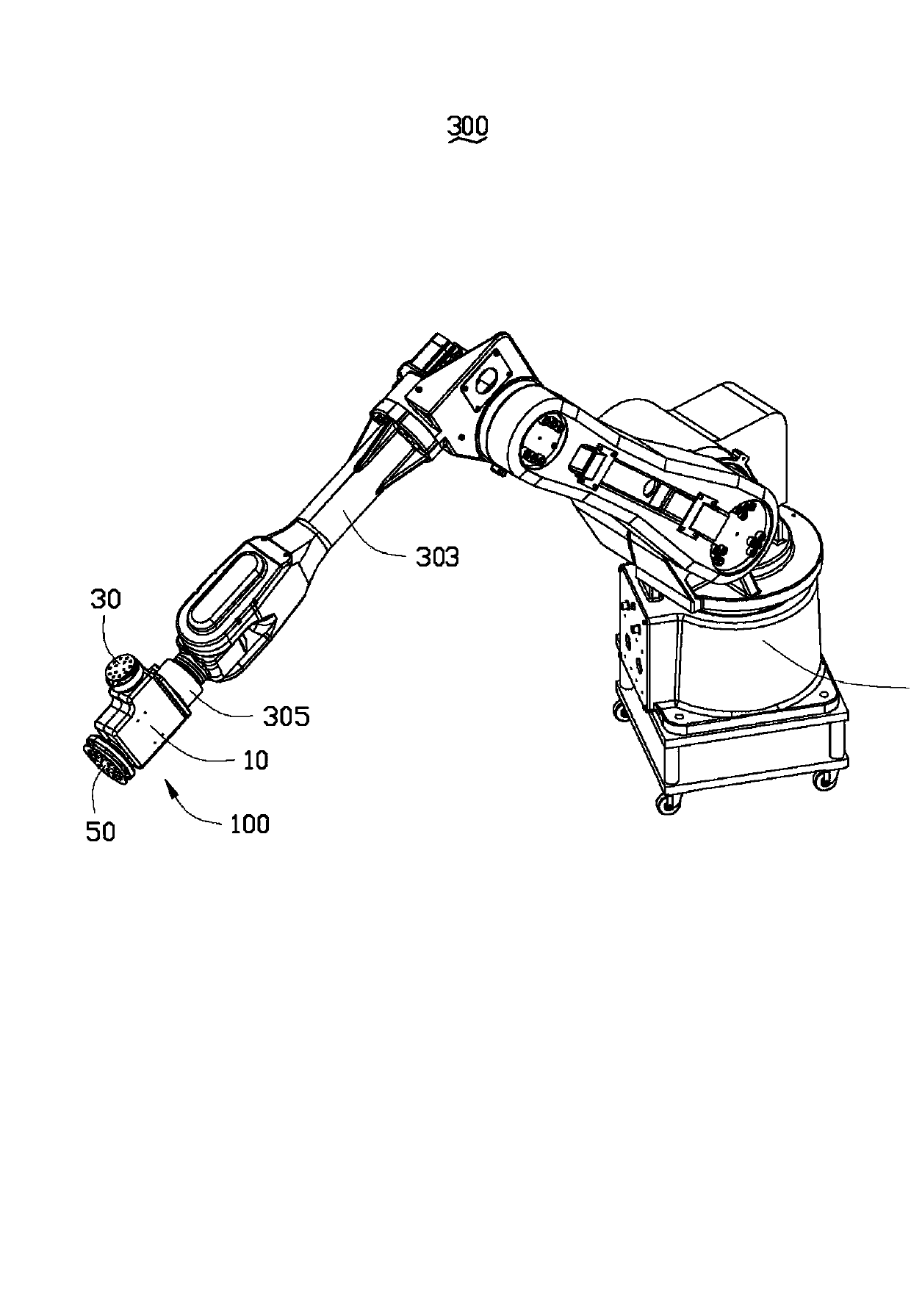

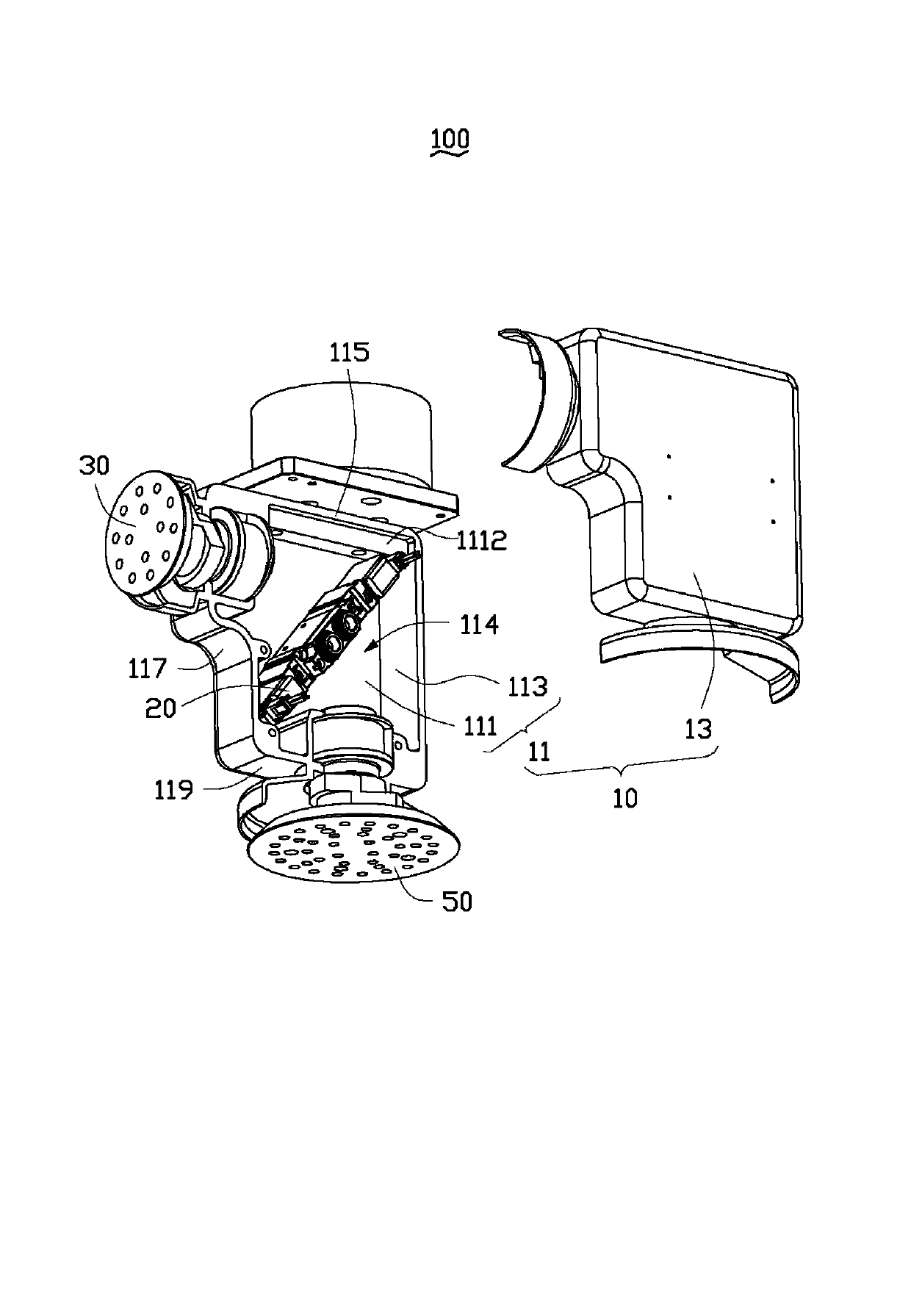

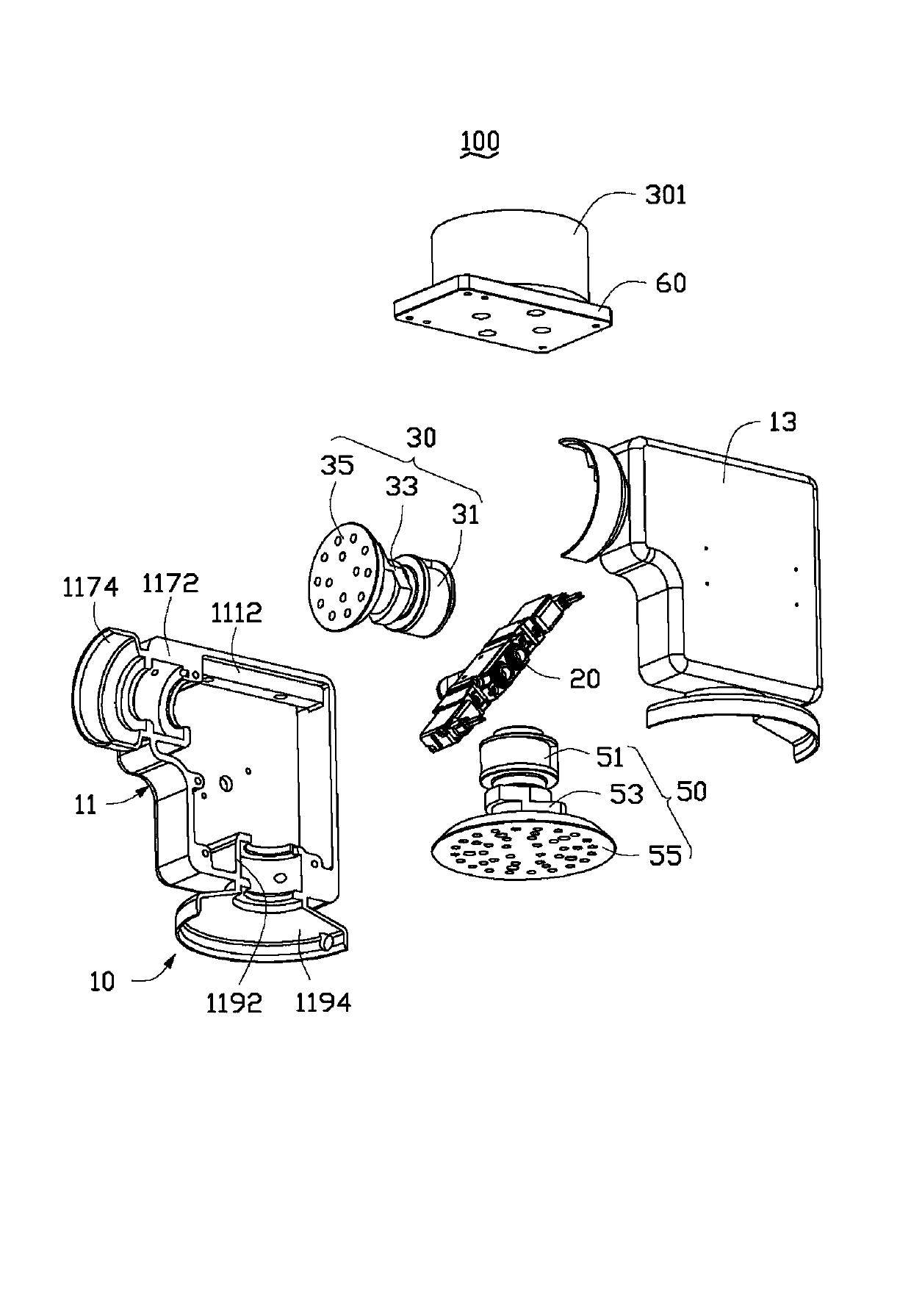

[0014] see figure 1 and figure 2 , the grinding robot 300 according to the embodiment of the present invention includes a control base 301 , a mechanical arm 303 and a grinding device 100 . The mechanical arm 303 is rotatably connected to the control base 301 , and the grinding device 100 is mounted on the end of the mechanical arm 303 away from the control base 301 and is electrically connected to the control base 301 . The mechanical arm 303 and the grinding device 100 cooperate with multiple faces of the workpiece 200 (see as Figure 5 ) for grinding. To save space, this embodiment focuses on the polishing device 100 .

[0015] In this embodiment, the workpiece 200 includes an arc-shaped bottom surface 201 and a peripheral wall 203 formed by extending and bending the peripheral edge of the bottom surface 201 . The peripheral edge of the peripheral wall 203 away from the bottom surface 201 forms a top surface 205 .

[0016] The grinding device 100 includes a housing 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com