Positioning and cleaning device for transmitting steel belt

A cleaning device and a technology for steel strips, applied to the cleaning method using tools, cleaning methods and utensils, transportation and packaging, etc., can solve the problems of defective products, increased material loss, and skewed steel strips, and achieve simple production and improved Work efficiency, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] For a better understanding of the present invention, further description will be given below in conjunction with the accompanying drawings and embodiments.

[0017]

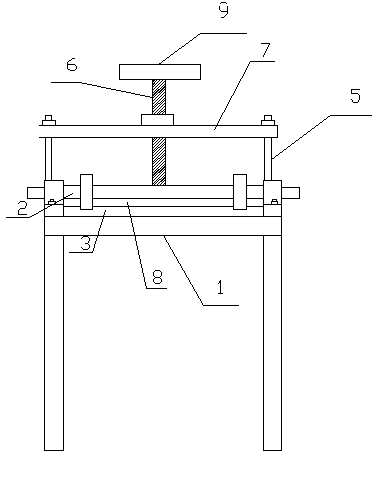

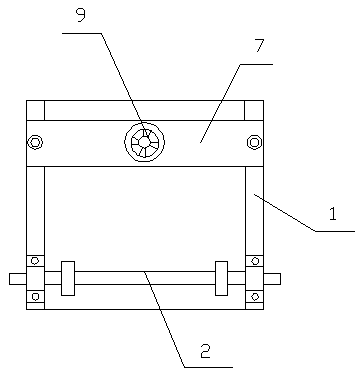

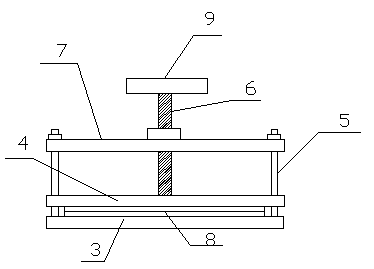

[0018] Example figure 1 , 2 As shown in , 3, this embodiment provides a positioning and cleaning device for conveying steel strips, including a bracket 1, a transmission roller 2, and a positioning and cleaning device, wherein the transmission roller 2 is rotatably and fixedly mounted on the bracket 1.

[0019] The positioning cleaning device is fixedly arranged on the support 1 and is located directly behind the conveying roller 2. The positioning cleaning device includes a lower pressing plate 3, an upper pressing plate 4, a support rod 5, a positioning screw 6, an adjusting disc 9, Anti-slip cleaning cloth 8; the lower platen 3 is fixedly arranged on the support 1, and the support rods 5 are respectively fixedly arranged at both ends, wherein each of the support rods 5 respectively passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com