Light-emitting diode (LED) bulb lamp

A technology of LED bulb lamps and LED lamp boards, which is applied in the direction of lampshades, cooling/heating devices of lighting devices, lighting and heating equipment, etc., and can solve the problems of uneven emission wavelength, brightness or voltage, affecting photoelectric parameters, and uneven distribution and other issues, to achieve ideal heat dissipation effect, save substrate material, and improve luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

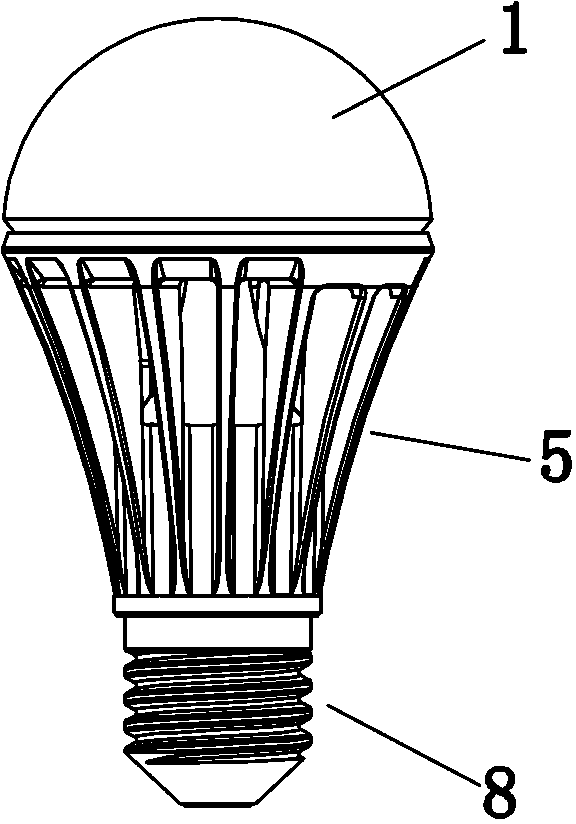

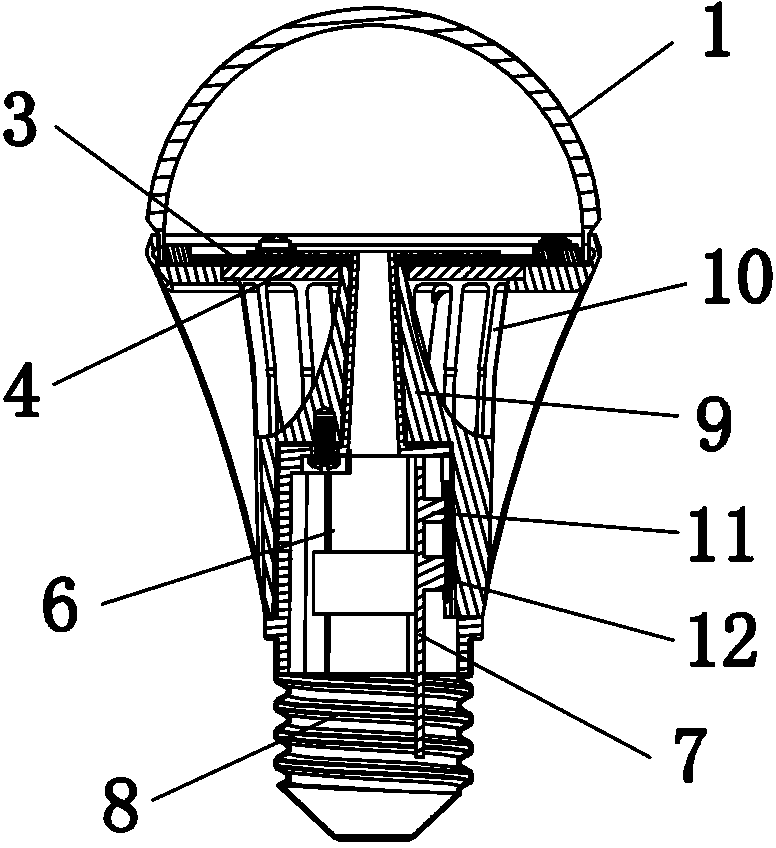

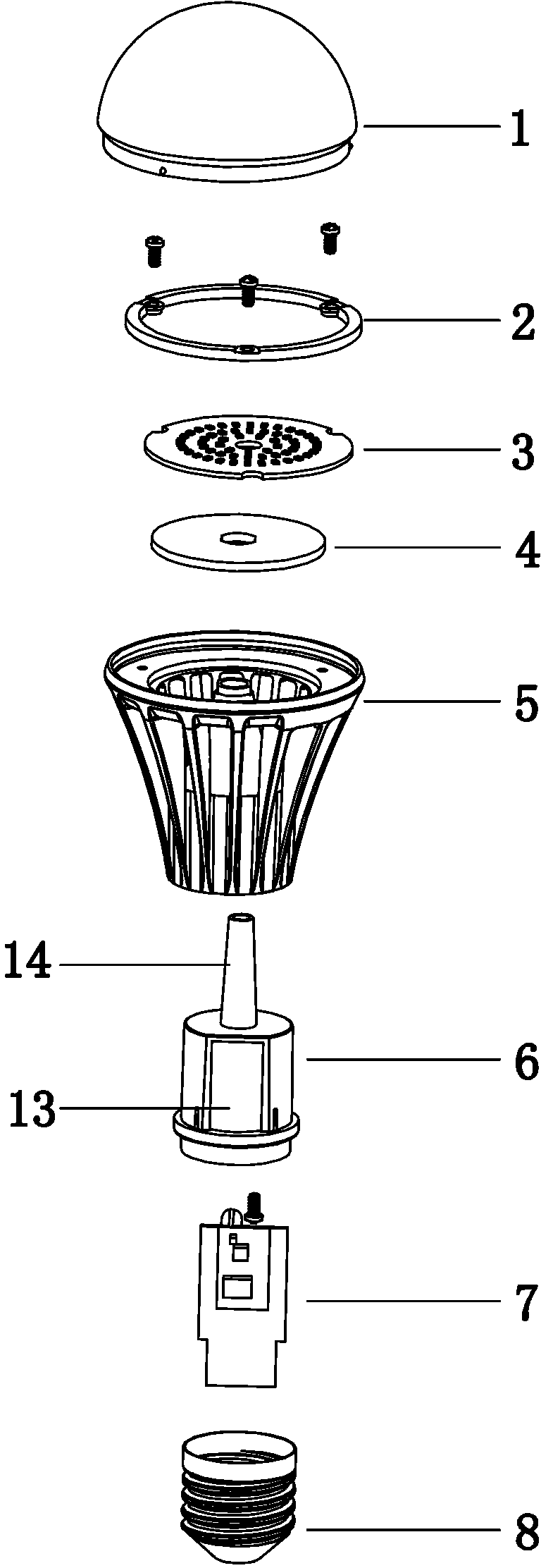

[0028] refer to figure 1 , figure 2 , image 3 , an LED bulb lamp, comprising a heat dissipation lamp body 5, a power supply accommodating cavity 15 is arranged in the heat dissipation lamp body 5, a power board 7 is installed in the power supply accommodating cavity 15, and a power supply board 7 is installed in the heat dissipation lamp body 5 One end is connected with a lamp holder 8 electrically connected to the power board 7 , and the other end is installed with a light-transmitting cover 1 , which can be connected with the heat-dissipating lamp body 5 through buckle or thread structure. The space formed by the light-transmitting cover 1 and the heat dissipation lamp body 5 is installed with an LED lamp board 3 electrically connected to the power supply board 7 through wires, and the end surface of the heat dissipation lamp body 5 is connected to the LED lamp board 3 A heat-conducting aluminum sheet 4 is installed between them, and the LED light board 3 is directly bon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com