Tube bundle supporting member for shell-and-tube heat exchanger

A technology for shell-and-tube heat exchangers and supports, which is applied in the direction of heat exchanger shells, heat exchange equipment, lighting and heating equipment, etc., and can solve the problems of reduced number of pipes, loose pipe structure, and difficulty in ensuring manufacturing accuracy, etc. , to achieve the effect of increasing compactness, solving edge leakage, and improving overall heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0041] Technical terms used in this invention

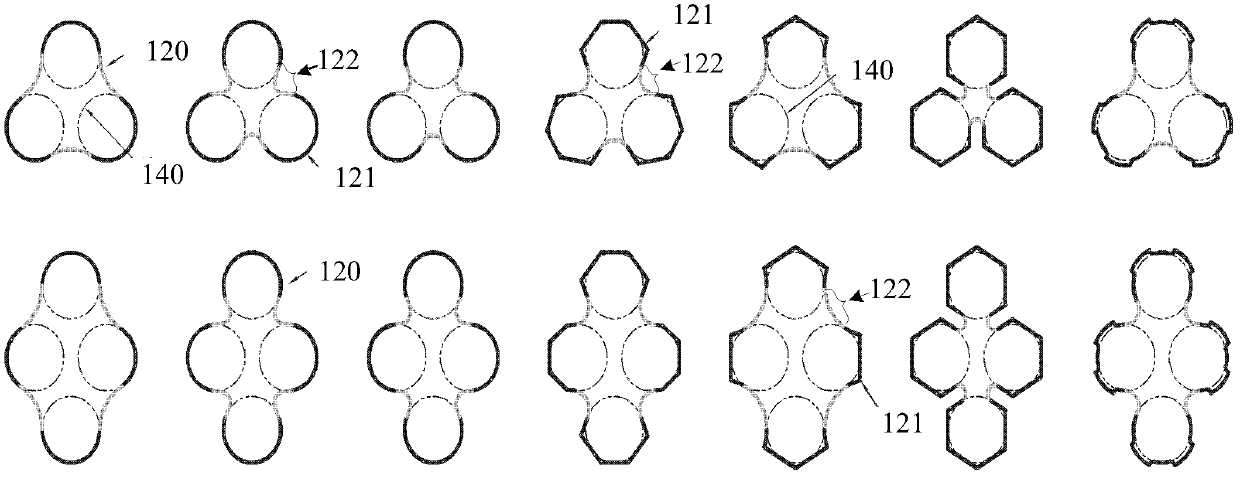

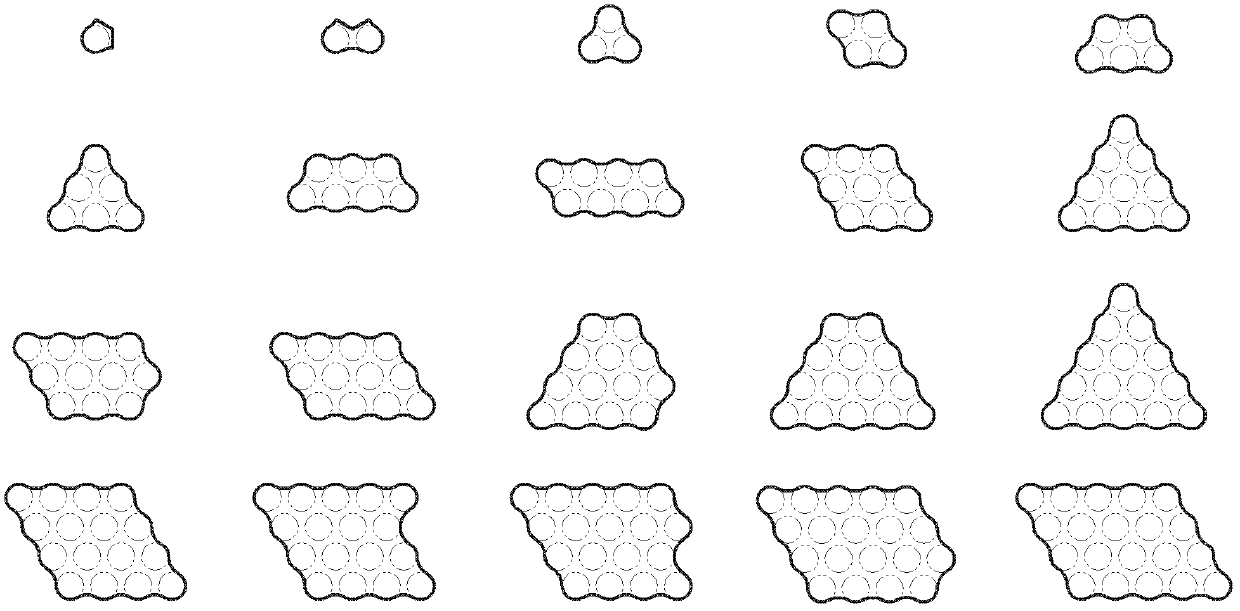

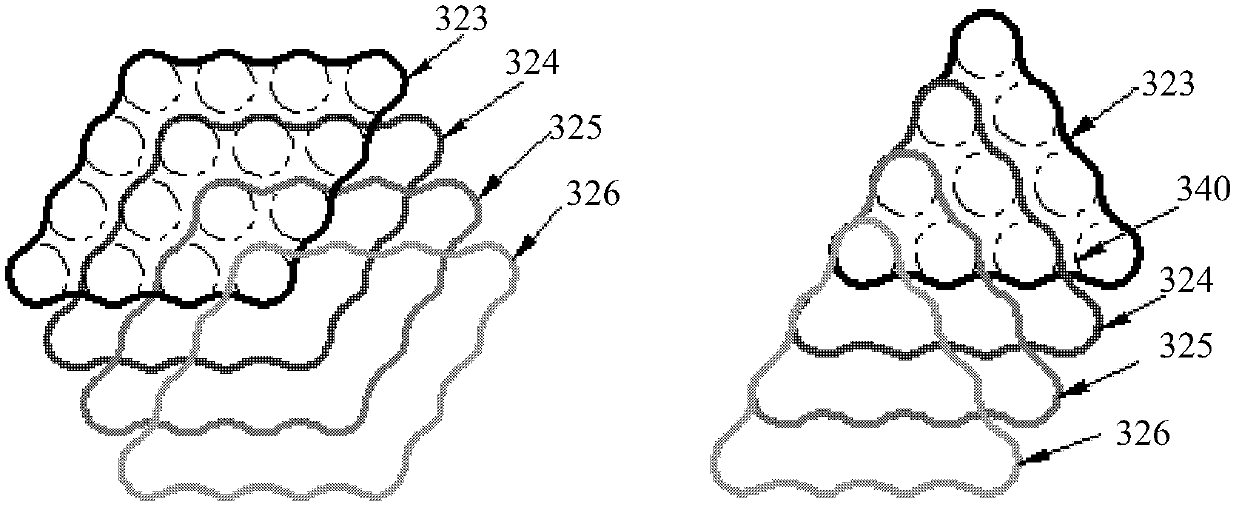

[0042] Heat exchange tube circle: refers to the closed contour formed by projecting the outer wall of the heat exchange tube onto a plane perpendicular to the axis of the heat exchange tube. A circle represents a heat exchange tube.

[0043] Tube hole circle: refers to the cross-sectional closed contour line of the hole used to support the heat exchange tube on the traditional arcuate support plate.

[0044] Basic pipe layout unit: refers to the triangle that determines the basic size of the heat exchange tube arrangement, and the apex of the triangle is the center of the heat exchange tube circle.

[0045] Adjacent pipe hole circles: refer to any two pipe hole circles in the basic pipe layout unit.

[0046] Support hole: refers to a hole that can accommodate at least one heat exchange tube, and the hole can at least limit at least one lateral movement of one heat exchange tube.

[0047] Standard support hole: refers to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com