Construction method of energy absorption curve of honeycomb paperboard under different environmental humidities

An energy absorption and environmental humidity technology, which is applied in measurement devices, instruments, and mechanical devices, etc., can solve the problems of unreliable prediction and evaluation of energy absorption performance, time-consuming and labor-intensive, and cumbersome data procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

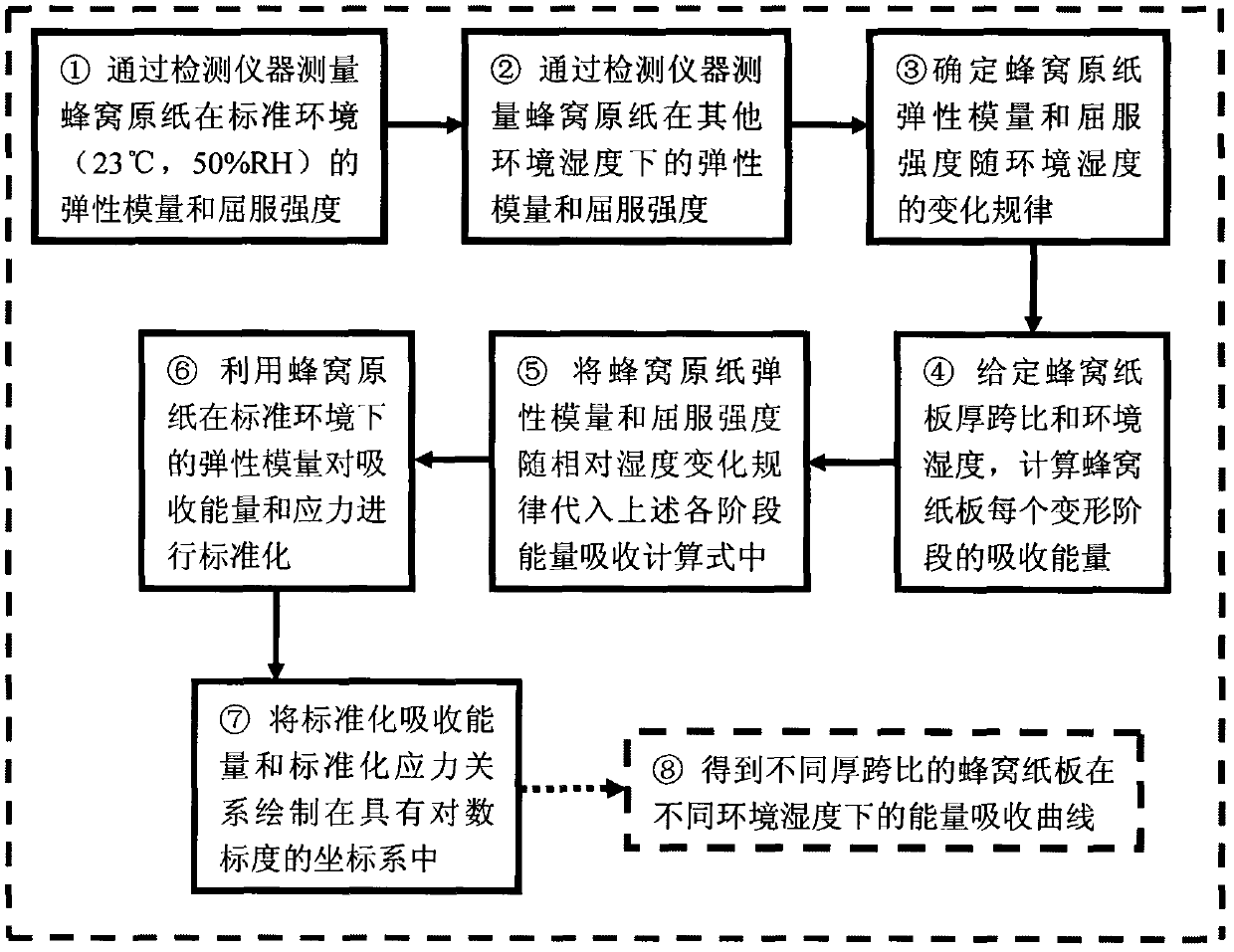

[0010] The present invention will be further described below in conjunction with drawings and embodiments.

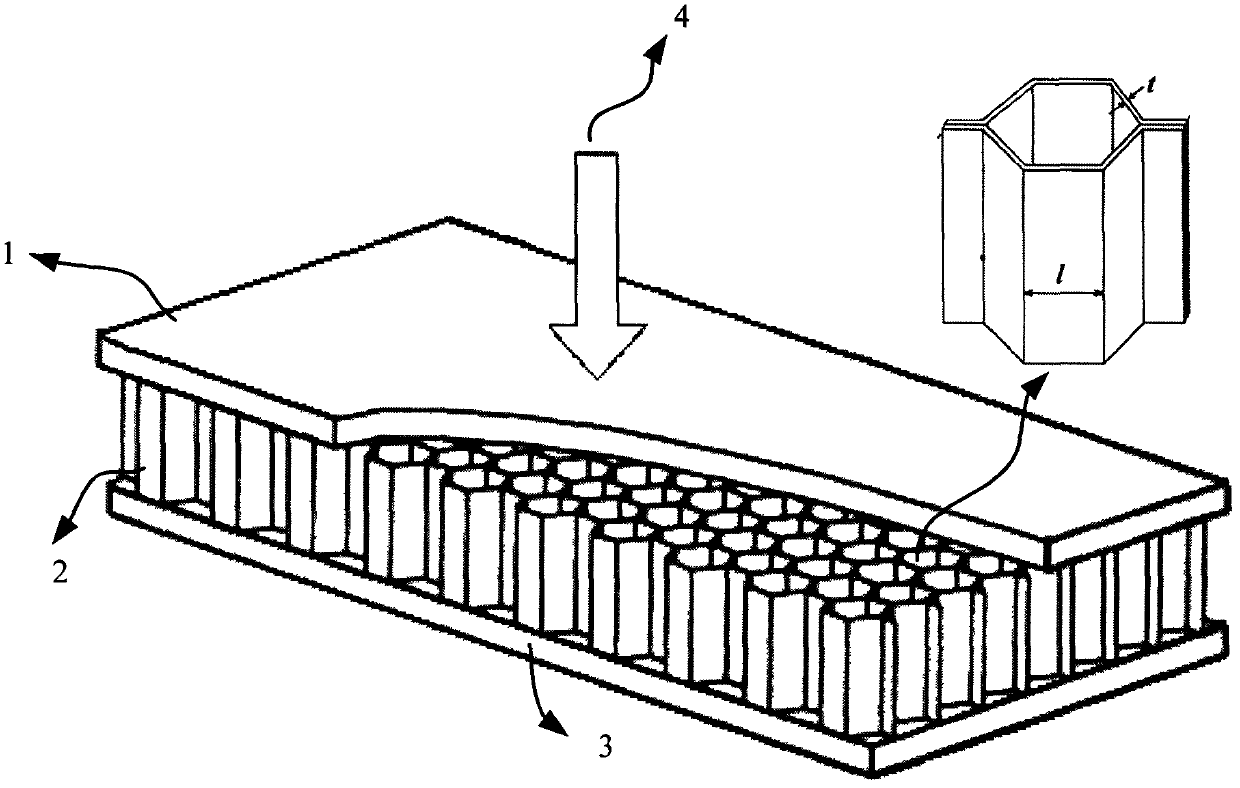

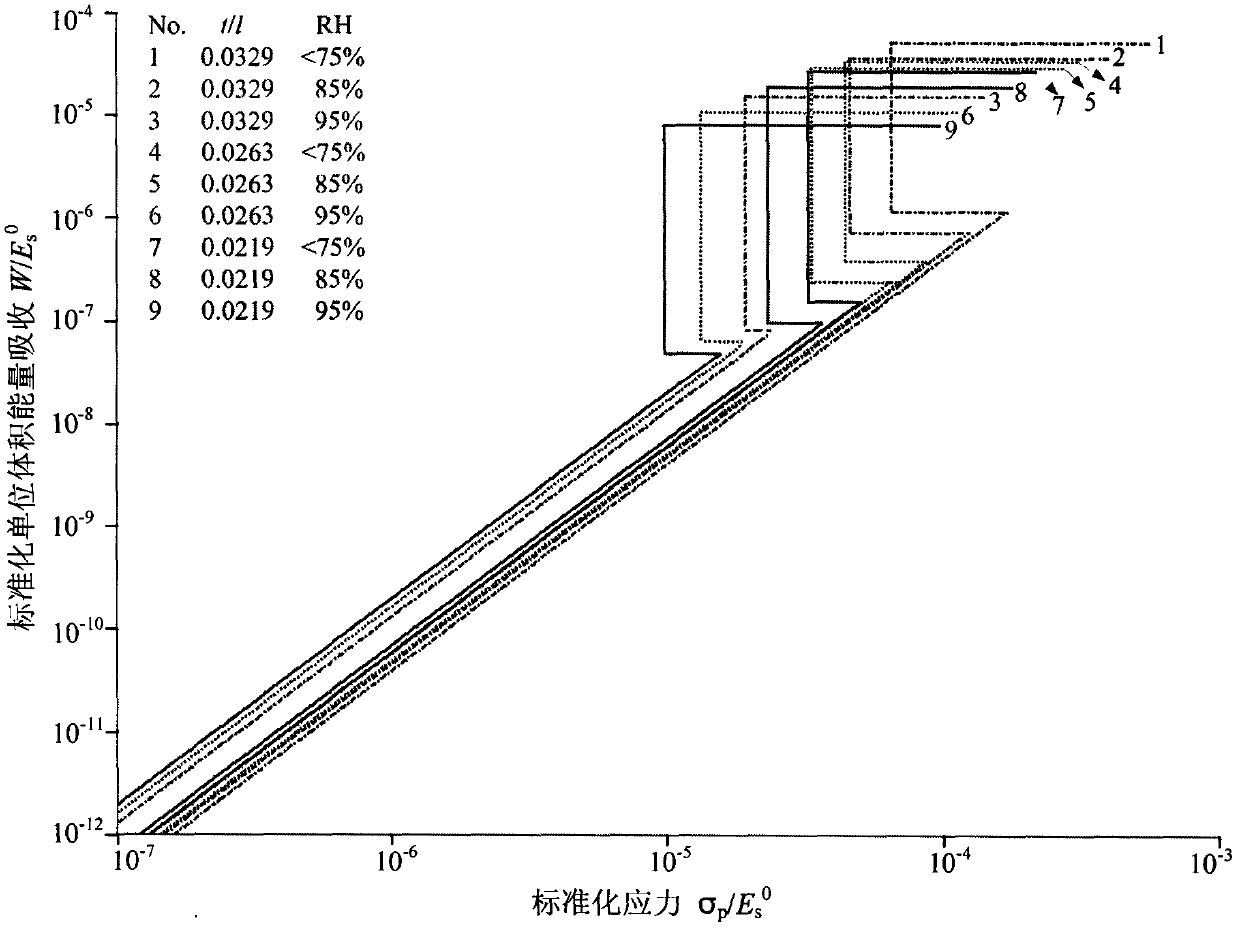

[0011] Such as figure 1 As shown, the honeycomb paperboard is a sandwich structure composed of outer paper 1, inner paper 3 and paper honeycomb core 2, and the raw material of the regular hexagonal paper honeycomb core 2 arranged in two dimensions is honeycomb base paper. The main structural parameters of regular hexagonal honeycomb cells are cell wall thickness t and cell side length l, both of which can be provided by honeycomb paperboard manufacturers.

[0012] Honeycomb paperboard can dissipate impact energy through plastic deformation, and is often used as an energy absorbing device or cushioning pad in logistics to protect products from damage in sudden drop impact accidents. When used for this purpose, the common way of applying force when the out-of-plane axial compression (external force acts on the thickness direction of the honeycomb paperboard, such as fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com