Electron beam section measuring system of high-current electron beam analysis meter

A measurement system and electron injection technology, applied in radiation measurement, measurement device, X/γ/cosmic radiation measurement, etc., can solve the problem of low efficiency, poor performance, and inability to measure the transmission characteristics of electromagnetic focusing electron injection electron injection optics Performance and other issues, to save time and simplify the measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

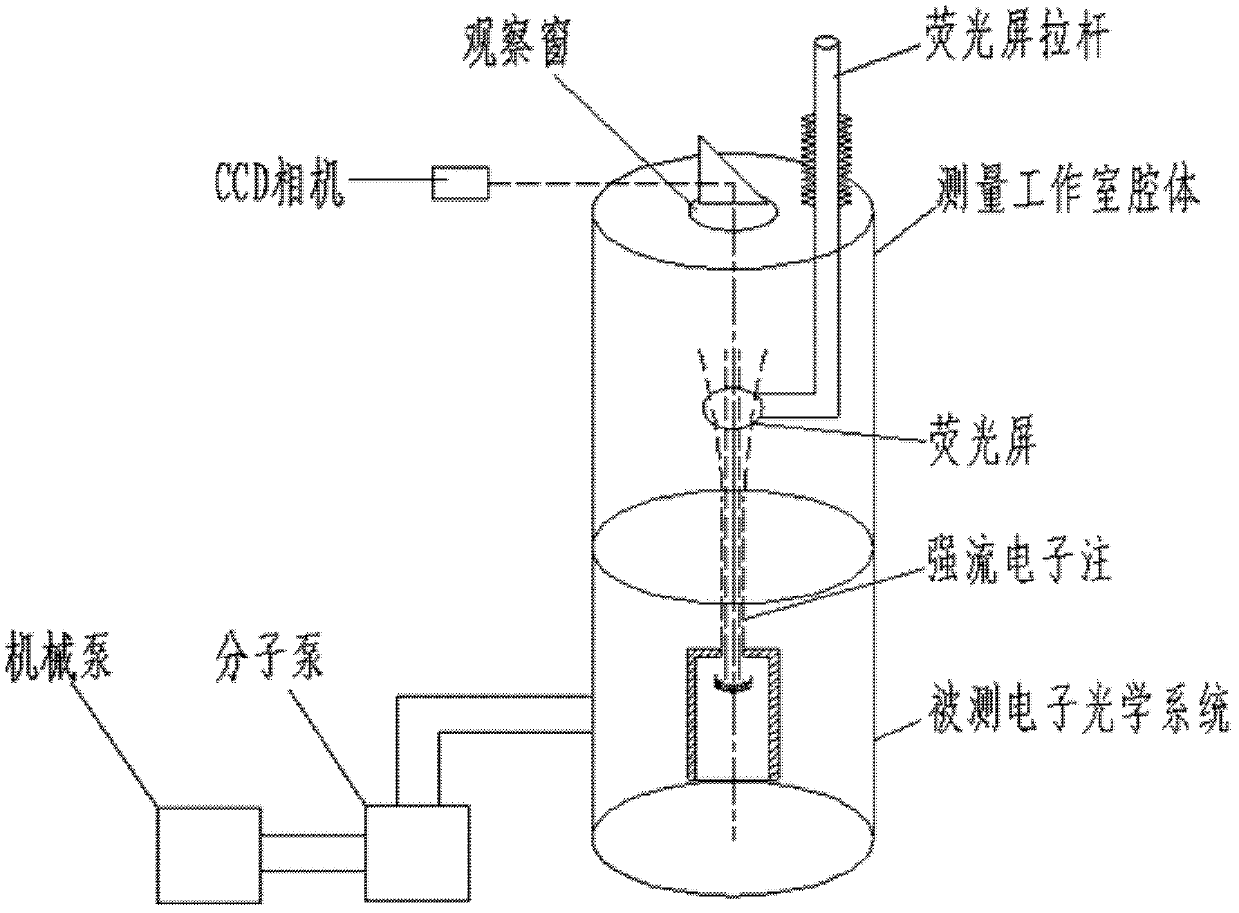

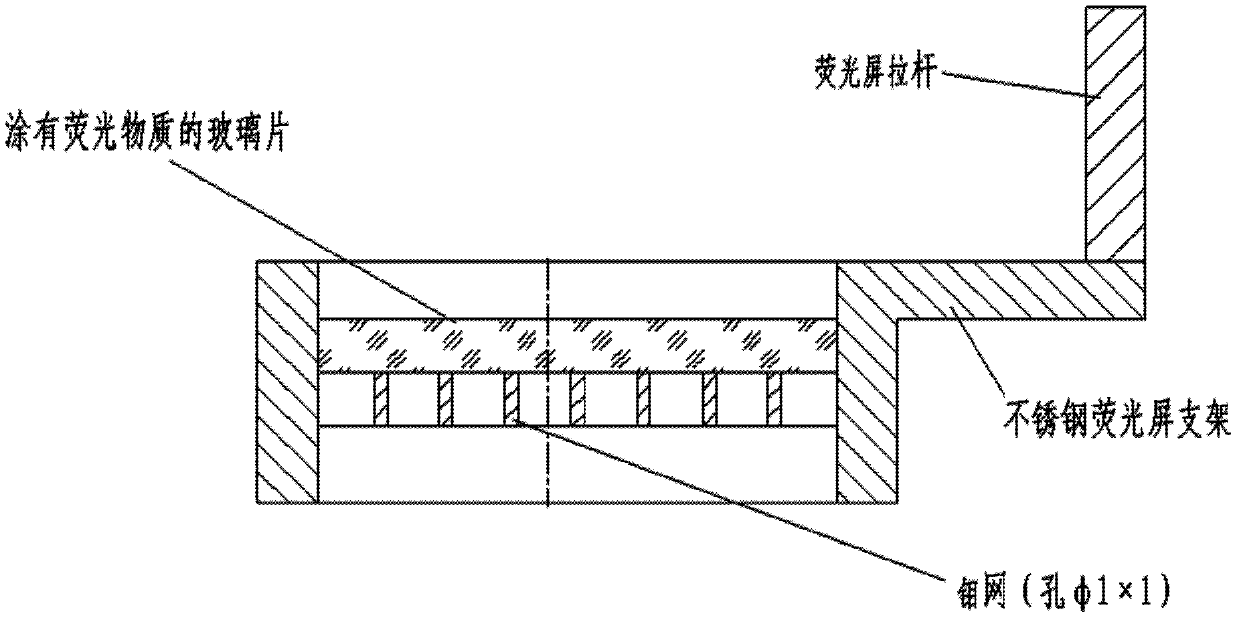

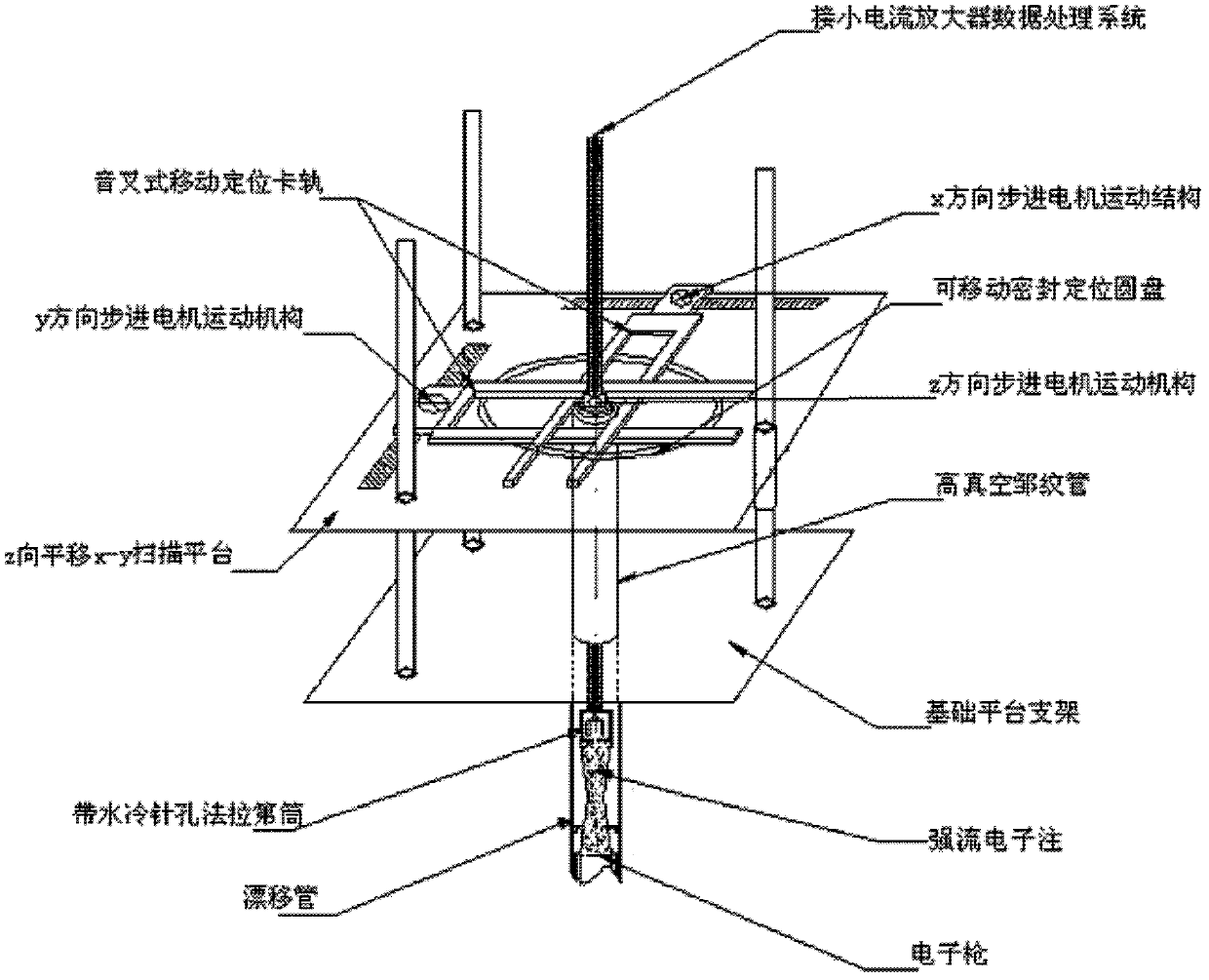

[0037] Figure 4 It is a schematic structural diagram of the electron beam cross-section measurement system of the high-current electron beam analyzer of the present invention, which is the main view; Figure 5 yes Figure 4 top view of Figure 6 It is a structural schematic diagram of the X-ray bremsstrahlung YAG detector of the present invention; Figure 7 It is an enlarged schematic diagram of the YAG support and movement mechanism of the present invention; Figure 8 It is an enlarged schematic view of the YAG main rod movement positioning mechanism and the optical observation camera part 501 of the present invention.

[0038] Such as Figure 4 , 5 As shown, the electron beam cross-section measurement system used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com