Flooded-type containment complete passive after-heat removal system

A passive waste heat and containment technology, which is applied in nuclear power generation, reactors, and greenhouse gas reduction, etc., can solve the problems of the loss of the final heat sink of the containment and the limited water capacity, so as to ensure the reliability and safety of the system operation, prevent the Evaporation, the effect of eliminating dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to understand the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

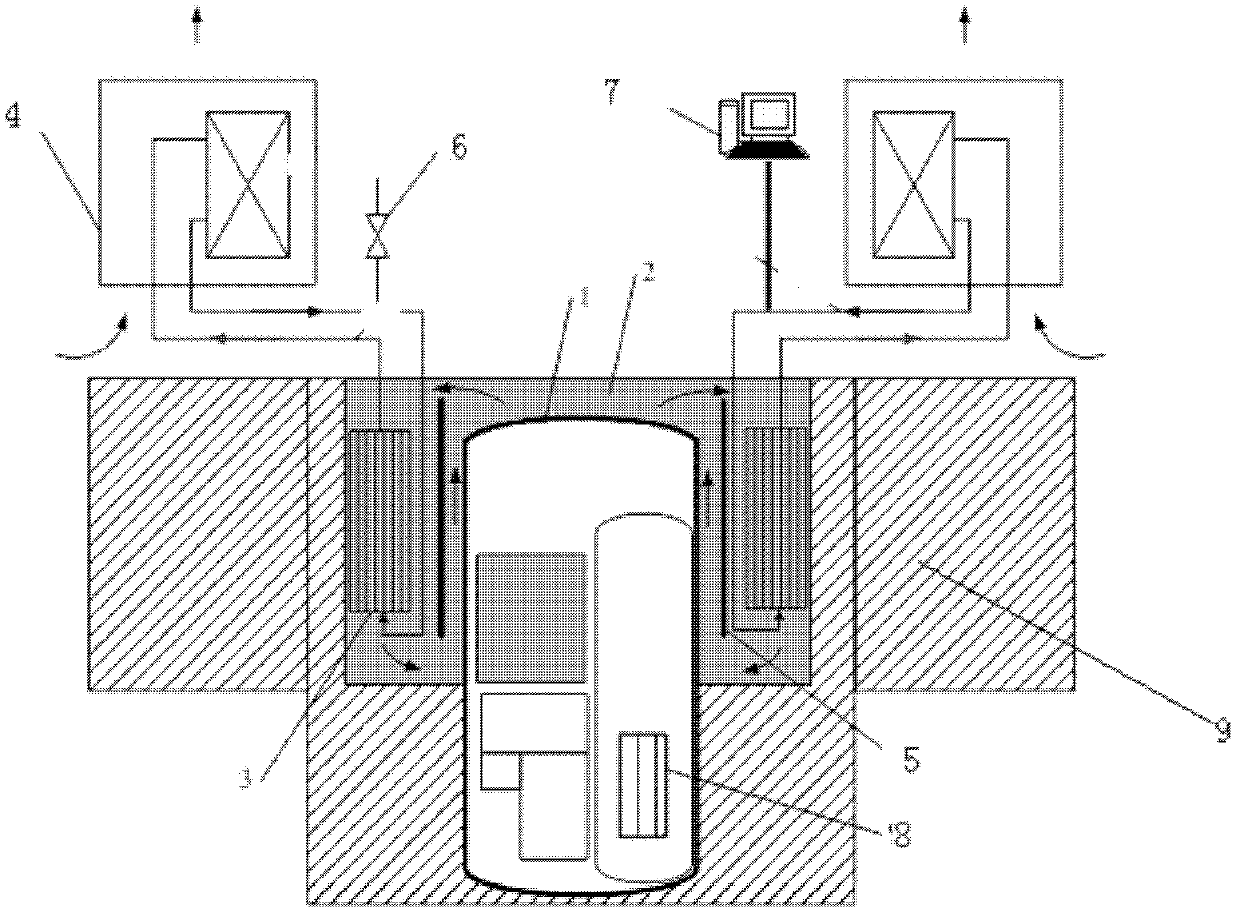

[0018] like figure 1 As shown, a water-flooded containment completely passive waste heat export system includes a separate cooling device 3, a chimney 4, a deflector 5, a vacuum device 6 and a vacuum monitoring device 7, and the deflector 5 adopts a relatively Made of a good metal material, such as a stainless steel plate, the deflector 5 is a frame structure closed all around, and several water holes are opened at the bottom of the deflector 5, and the height of the part with the water holes at the bottom of the deflector 5 is 0.5 ~ 10m, can be 0.5m, 2m or 10m, to provide a passage for the flow of cooling water. The deflector 5 is placed at the bottom of the pool 9. The deflector 5 surrounds the containment vessel 1 and is immersed in the cooling water. There is a space around the deflector 5 and the pool 9. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com