Light emitting diode device

A technology of light-emitting diodes and electrodes, applied in electrical components, electrical solid-state devices, circuits, etc., can solve problems such as increased process time and cost, decreased internal quantum efficiency, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

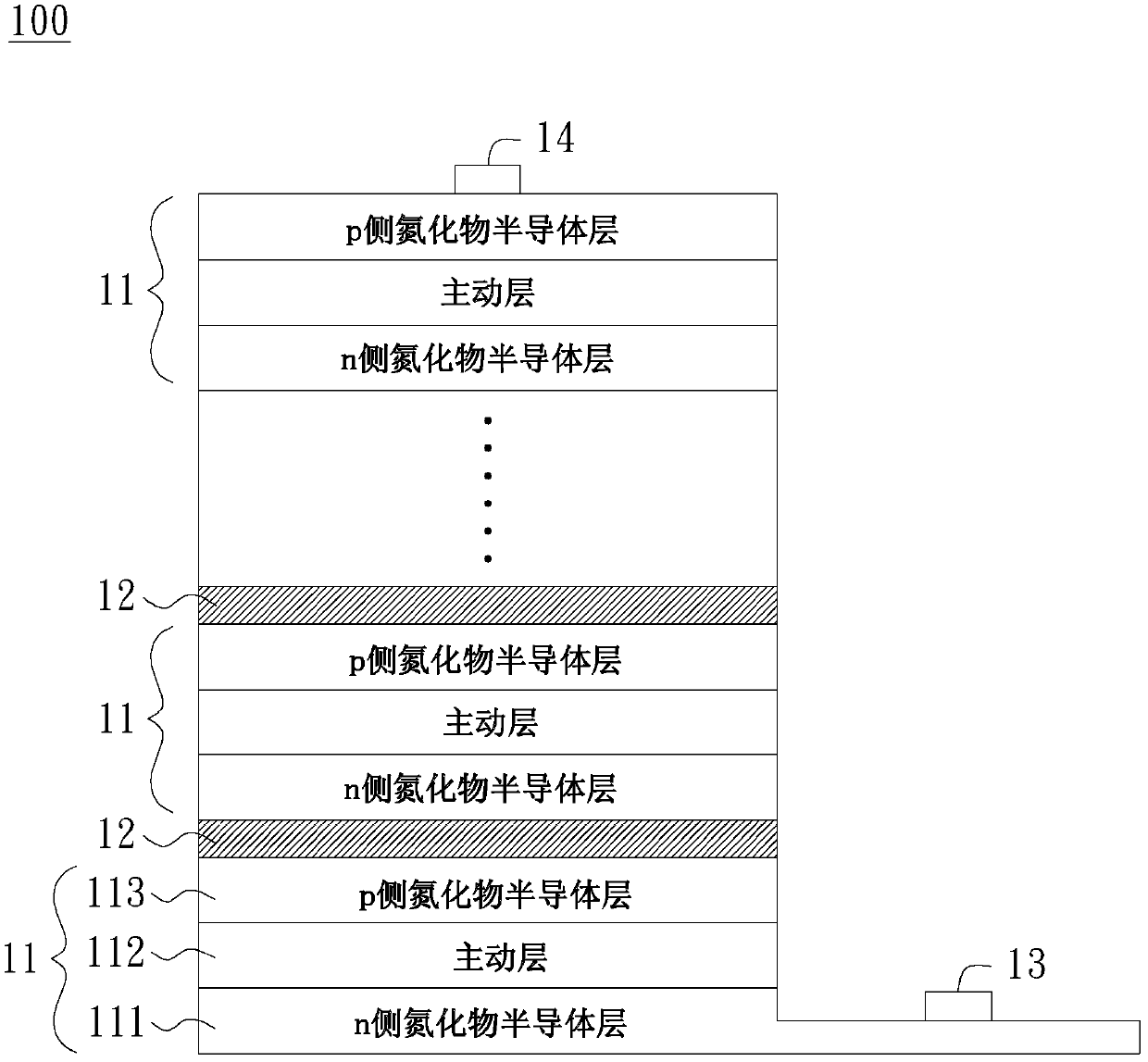

[0027] An embodiment of the invention discloses a light emitting diode (LED) device, which includes at least stacked LED units. figure 1 A cross-sectional view of a stacked LED unit 100 according to an embodiment of the present invention is shown, which includes a plurality of epitaxial structures 11 , and a tunnel junction 12 is formed between adjacent epitaxial structures 11 . Each tunnel junction 12 vertically stacks adjacent epitaxial structures 11 during the epitaxial process to form a stacked LED unit 100 . In this embodiment, the epitaxial structure 11 includes an n-side nitride semiconductor layer 111, an active layer 112 and a p-side nitride semiconductor layer 113, wherein the active layer 112 is between the n-side nitride semiconductor layer 111 and the p-side nitride semiconductor layer. Between layers 113. The tunnel junction 12 is located between the p-side nitride semiconductor layer 113 of one epitaxial structure 11 and the n-side nitride semiconductor layer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com