Photosensitive resin composition, and photosensitive resin film and color filter using same

一种感光性树脂、组成物的技术,应用在光学、光学元件、光机械设备等方向,能够解决可靠性低、不保证充分固化、彩色滤光片的材料无法固化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1-1

[0270] By mixing 138g of 9,9'-bis(4-glycine siloxyphenyl) fluorine (Hear Chem), 54g of 4-(methylthio)thiophenol (TCI), 1.4g of benzyl triethyl ammonium chloride (Daejung Chemicals & Metals Co.Ltd.), 1 g of triphenylphosphine (Aldrich Corporation), 128 g of propylene glycol acetate methylethylene glycol (Daejung Chemicals Daicel Chemicals Company) and 0.5 g of hydroquinone were placed in the reactor, and then the reactor was heated up to 120° C. and maintained for 12 hours to synthesize the compound represented by Chemical Formula A-1.

[0271] [Chemical formula A-1]

[0272]

Synthetic example 1-2

[0274] By adding 138g of 9,9'-bis(4-glysiloxyphenyl) fluorine (Hear Chem company), 54g of 2-(methylsulfonyl)ethane-1-thiol (TCI company), 1.4g of Benzyltriethylammonium chloride (Daejung Chemicals & Metals Co. Ltd.), 1 g of triphenylphosphine (Aldrich Corporation), 128 g of propylene glycol acetate methylethylene glycol (Daicel Chemicals Company) and 0.5 g of hydroquinone were placed in the reactor, and then the reactor was heated up to 120° C. and kept for 12 hours to synthesize the compound represented by Chemical Formula A-2 compound.

[0275] [Chemical formula A-2]

[0276]

Synthetic example 2-1

[0278] By adding 60 g of the compound represented by chemical formula A-1, 16 g of 3,3',4,4'-thiodiphthalic anhydride (American chemical Inc.), 3.4 g of 5- Norbornene-2,3-dicarboxylic anhydride (TCI Corporation), 20 g of propylene glycol methyl ethyl acetate (Daicel Chemicals Company) and 0.1 g of N,N'-tetramethyl chloride Ammonium was placed in the reactor, and then the reactor was heated up to 120° C. and maintained for 2 hours to synthesize the compound represented by Chemical Formula B-1 (weight average molecular weight: 5,600 g / mol).

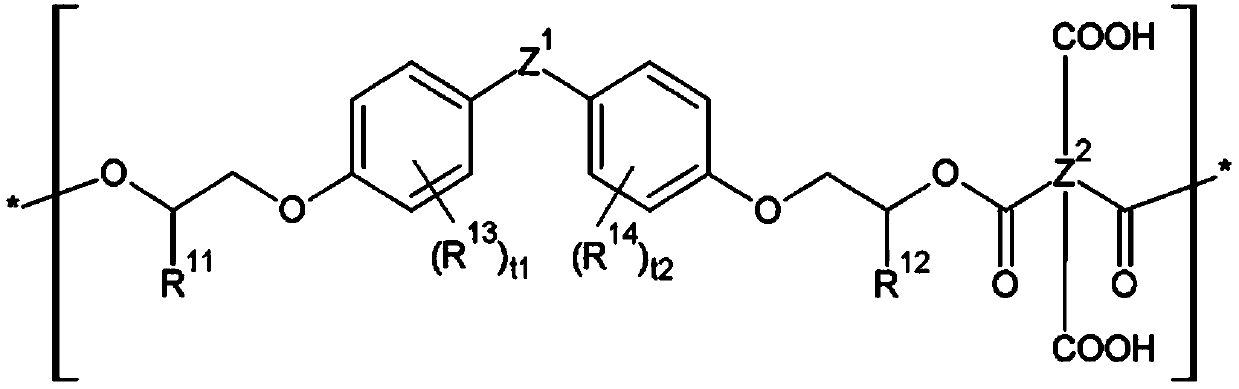

[0279] [Chemical formula B-1]

[0280]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com