A preparation method of titanium dioxide particles whose surface is doped with rare earth elements

A technology of titanium dioxide and rare earth elements, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc. can not stimulate other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

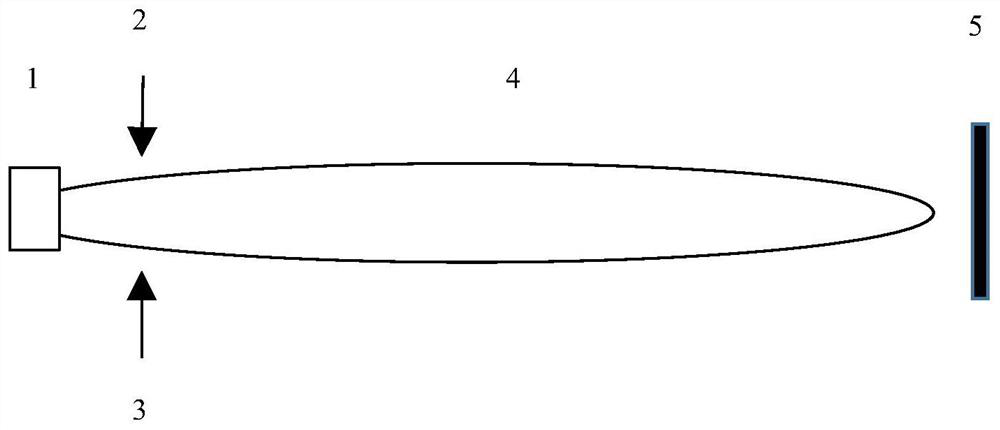

[0022] The equipment structure of the reaction device

[0023] The schematic diagram of the reaction device used in the present invention is as figure 1 As shown, its main structural units are: 1. Plasma spray gun, 2. Powder inlet, 3. Liquid material inlet, 5. Powder collector. When working, the plasma spray gun converts the working gas argon and hydrogen into high-energy plasma, which is ejected from the nozzle to form a plasma jet (4) with a temperature of up to 17000 °C. After the plasma jet is stabilized, use N 2 The carrier gas sends the sprayed titanium dioxide powder particles into the plasma radially through the powder inlet 2, and the powder will be rapidly heated to a molten or semi-molten state in the high-temperature plasma jet, and at the same time, it is synchronously fed into the plasma through the symmetrically positioned liquid material inlet 3 Rare earth element precursors are gasified at high temperature to dope titanium dioxide, and then collected by the ...

Embodiment 2

[0025] Surface doped with lanthanum ions

[0026] (1) Start the plasma spray gun: the working power of the spray gun is 55kW, the argon gas in the plasma gas is 40 slpm, and the hydrogen gas is 11 slpm.

[0027] (2) Implement doping: use N 2 The gas sends titanium dioxide powder particles with an average particle size of 15-40 μm into the plasma jet, the carrier gas flow rate is 5L / min, and the powder feeding amount is 15g / min. At the same time, the aqueous solution of lanthanum nitrate with a mass ratio of 5% is continuously sent into the plasma jet with a pressure of 1.5 mbr and a flow rate of 30 mL / min, and titanium dioxide is doped after high-temperature ionization.

[0028] (3) After the temperature of the collector is cooled to room temperature, collect the reaction product.

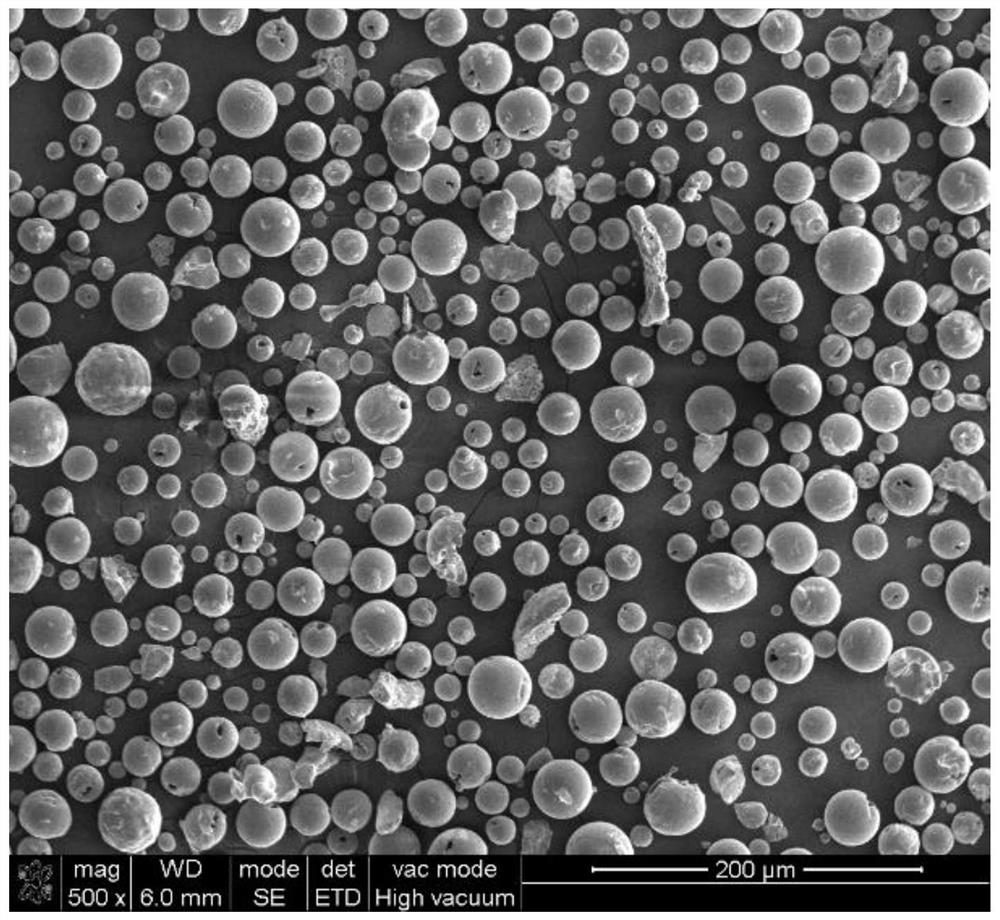

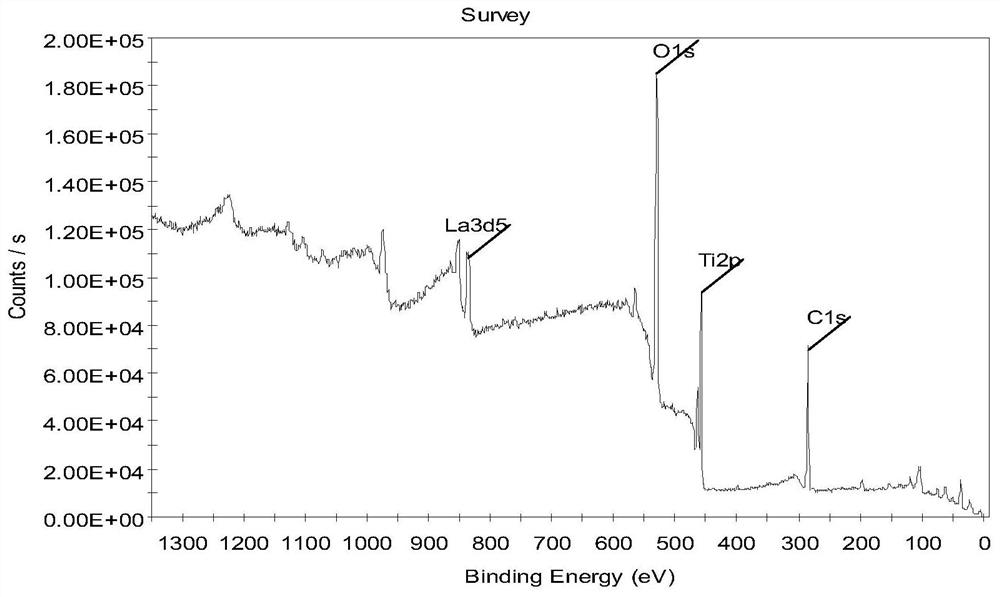

[0029] The as-prepared TiO surface doped with lanthanum ions 2 Powder SEM photos are attached figure 2 As shown, it can be observed from the figure that the particle size of the powder is unif...

Embodiment 3

[0031] surface doped with cerium ions

[0032] Titanium dioxide particles doped with cerium ions can be prepared by changing the rare earth precursor in step (2) of Example 2 to cerium nitrate, and keeping other steps and conditions unchanged. After doping with rare earth ions, the titanium dioxide particles not only have a good response to ultraviolet light, but also have a stable response to visible light with a wavelength of 400-600nm. Obviously, using it as a photocatalyst has a higher utilization efficiency of sunlight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com