Preparation method of titanium dioxide particle with surface doped with rare earth element

A technology of titanium dioxide and rare earth elements, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc. Can not be excited and other problems, to achieve the effect of high crystallinity, ideal catalytic activity, and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

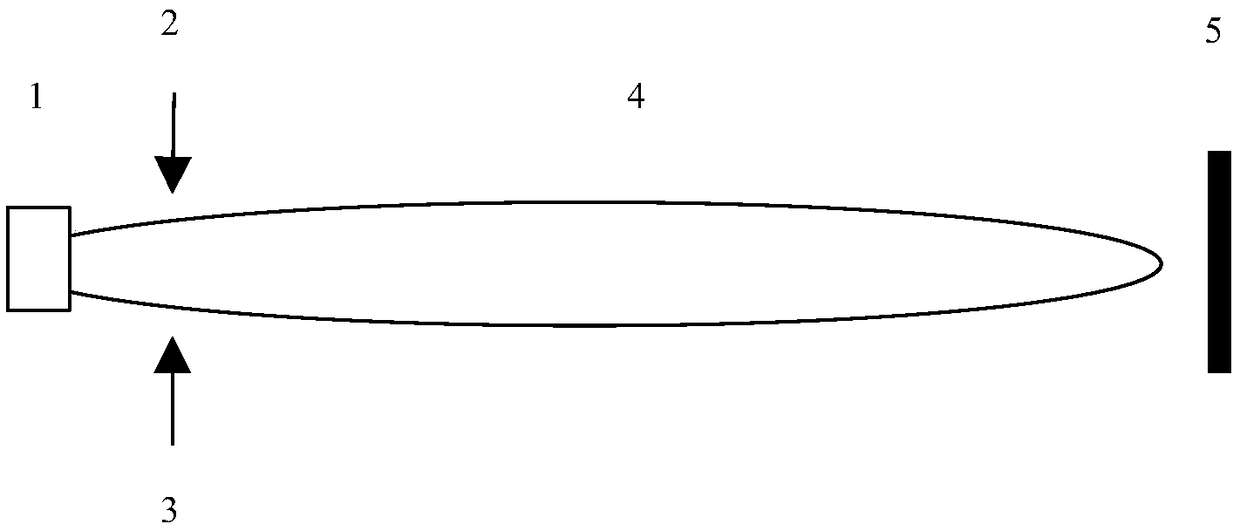

[0022] Equipment structure of reaction device

[0023] The schematic diagram of the reaction device used in the present invention is as figure 1 As shown, the main structural units are: 1. Plasma spray gun, 2. Powder inlet, 3. Liquid material inlet, 5. Powder collector. When working, the plasma spray gun converts the working gas argon and hydrogen into high-energy plasma, which is ejected from the nozzle to form a plasma jet of up to 17000°C (4). After the plasma jet is stable, use N 2 The carrier gas sends the sprayed titanium dioxide powder particles radially into the plasma through the powder inlet 2. The powder will be rapidly heated to a molten or semi-molten state in the high-temperature plasma jet, and at the same time, it will be simultaneously fed through the symmetrical liquid inlet 3 The rare earth element precursor is doped with titanium dioxide after high temperature gasification, and then collected by the powder collector 5. The maximum power of this system can rea...

Embodiment 2

[0025] Lanthanum ion doped on the surface

[0026] (1) Start the plasma spray gun: the working power of the spray gun is 55kW, the argon in the plasma gas is 40slpm, and the hydrogen is 11slpm.

[0027] (2) Implement doping: use N 2 The gas sends titanium dioxide powder particles with an average particle size of 15-40μm into the plasma jet, the carrier gas flow rate is 5L / min, and the powder feeding rate is 15g / min. At the same time, an aqueous solution of lanthanum nitrate with a mass ratio of 5% was continuously fed into the plasma jet with a pressure of 1.5 mbr and a flow rate of 30 mL / min. After high temperature ionization, the titanium dioxide was doped.

[0028] (3) After the temperature of the collector is cooled to room temperature, collect the reaction product.

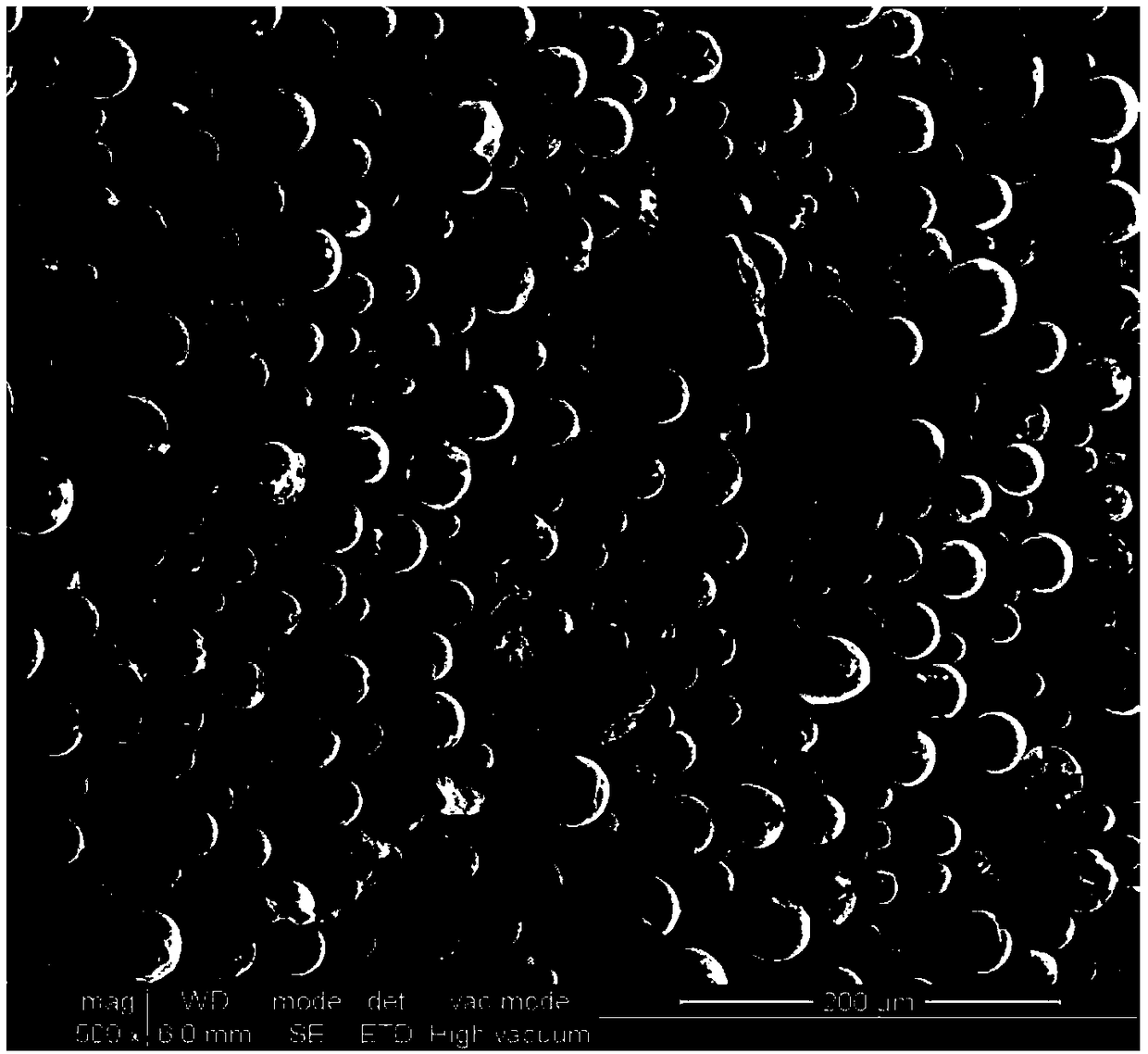

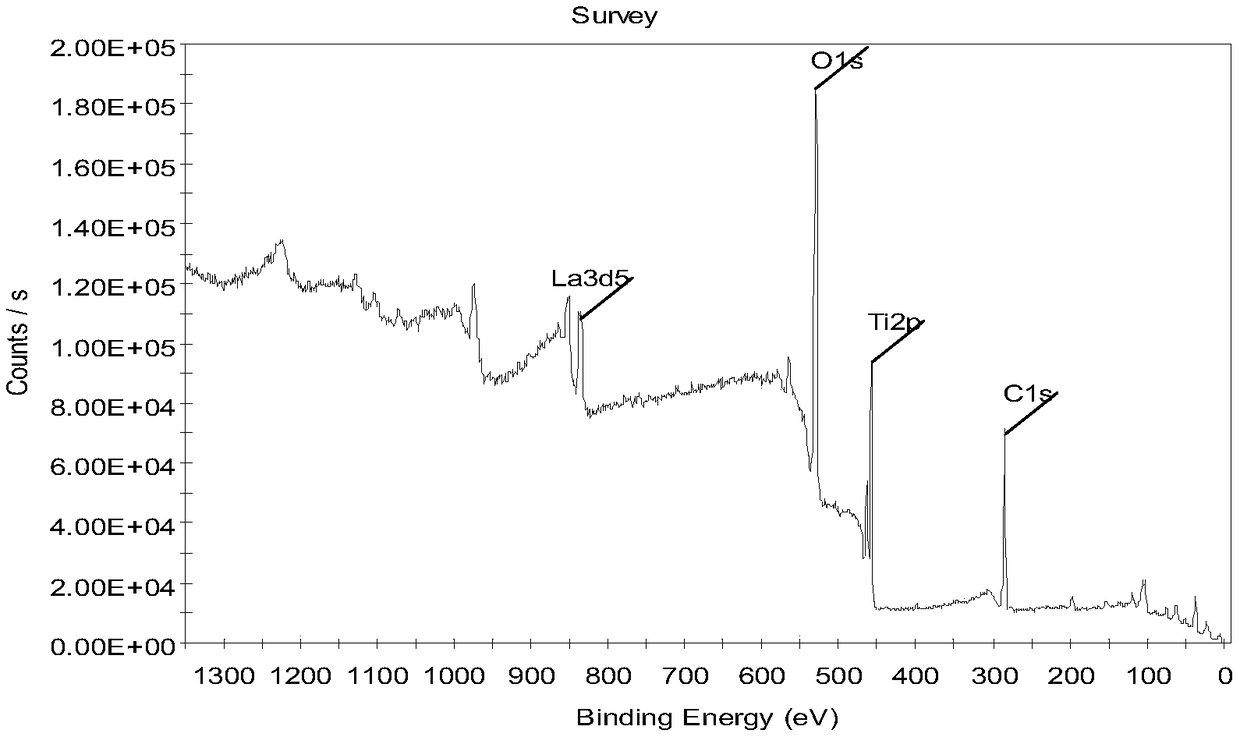

[0029] The prepared TiO doped with lanthanum ions 2 The powder SEM photo is attached figure 2 As shown in the figure, it can be observed that the particle size of the powder is uniform, the shape of the powder parti...

Embodiment 3

[0031] Surface doped with cerium ion

[0032] The rare earth precursor in step (2) in Example 2 is changed to cerium nitrate, and other steps and conditions remain unchanged, and cerium ion-doped titanium dioxide particles can be prepared. After being doped with rare earth ions, the titanium dioxide particles not only have a good response to ultraviolet light, but also have a stable response to visible light with a wavelength of 400 to 600 nm. Obviously, using it as a photocatalyst has a higher utilization efficiency of sunlight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com