Composite cylinder block of an internal combustion engine

一种内燃发动机、气缸体的技术,应用在发动机元件、机器/发动机、汽缸等方向,能够解决增加成本等问题,达到节省成本和重量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

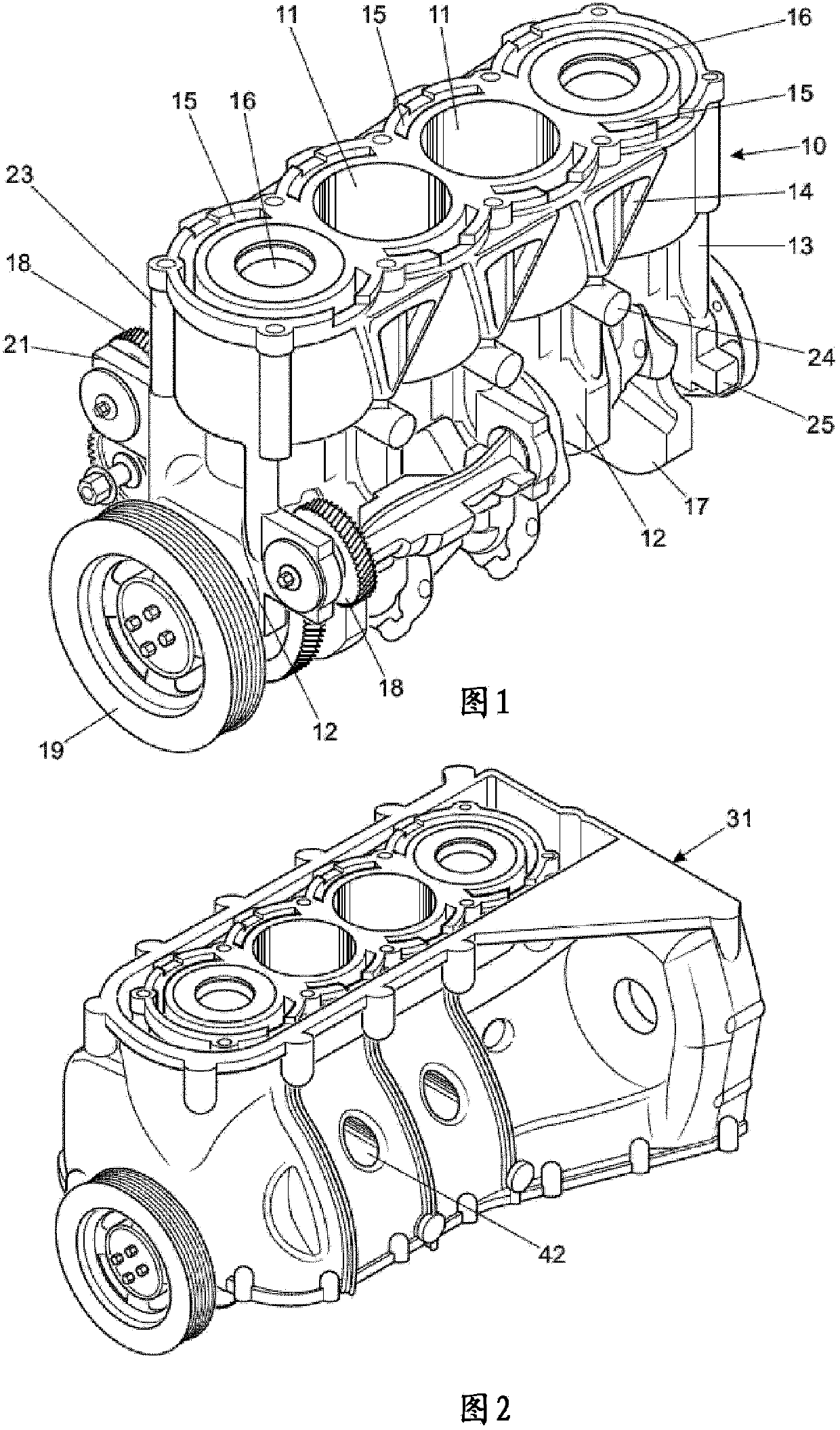

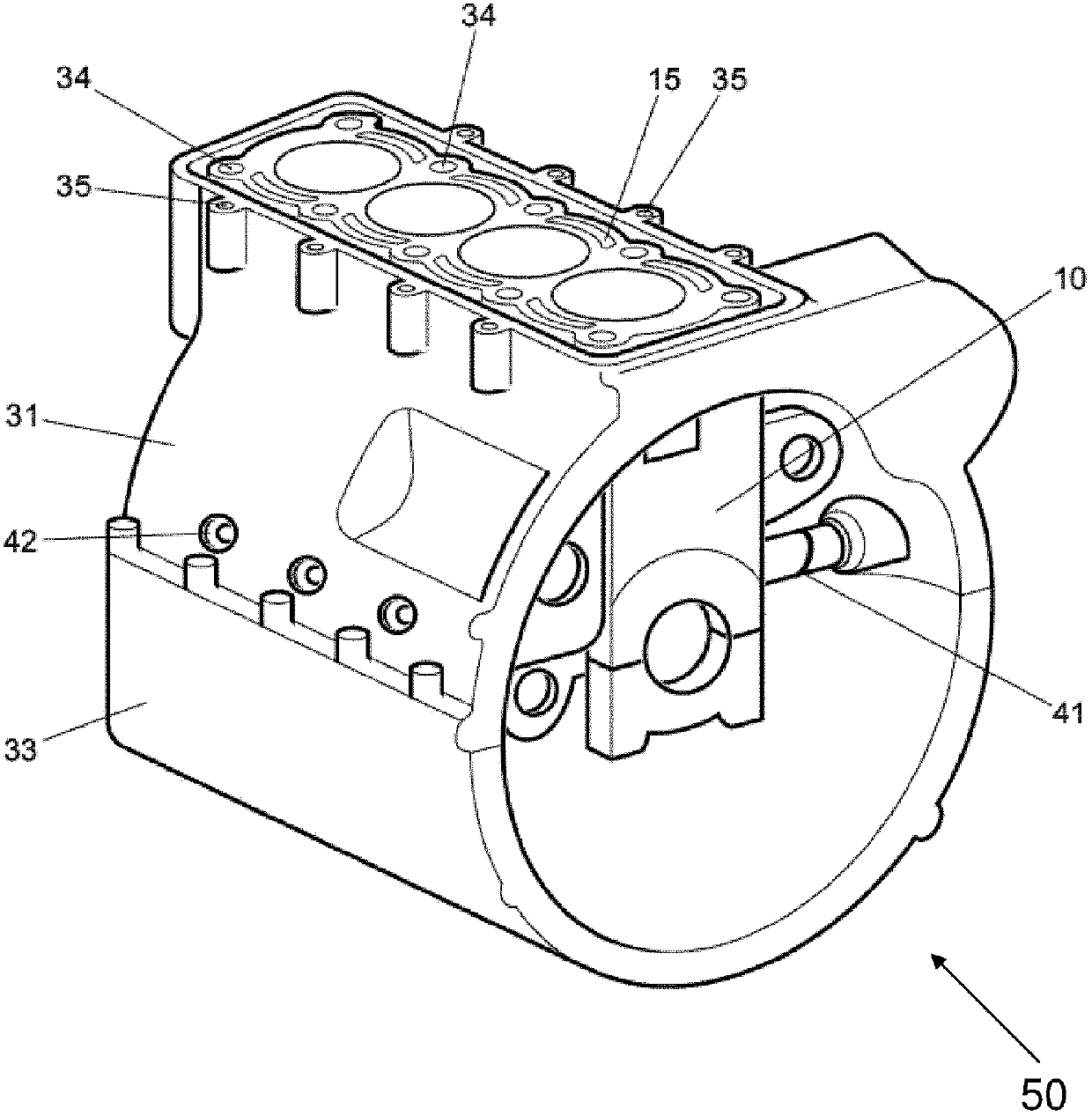

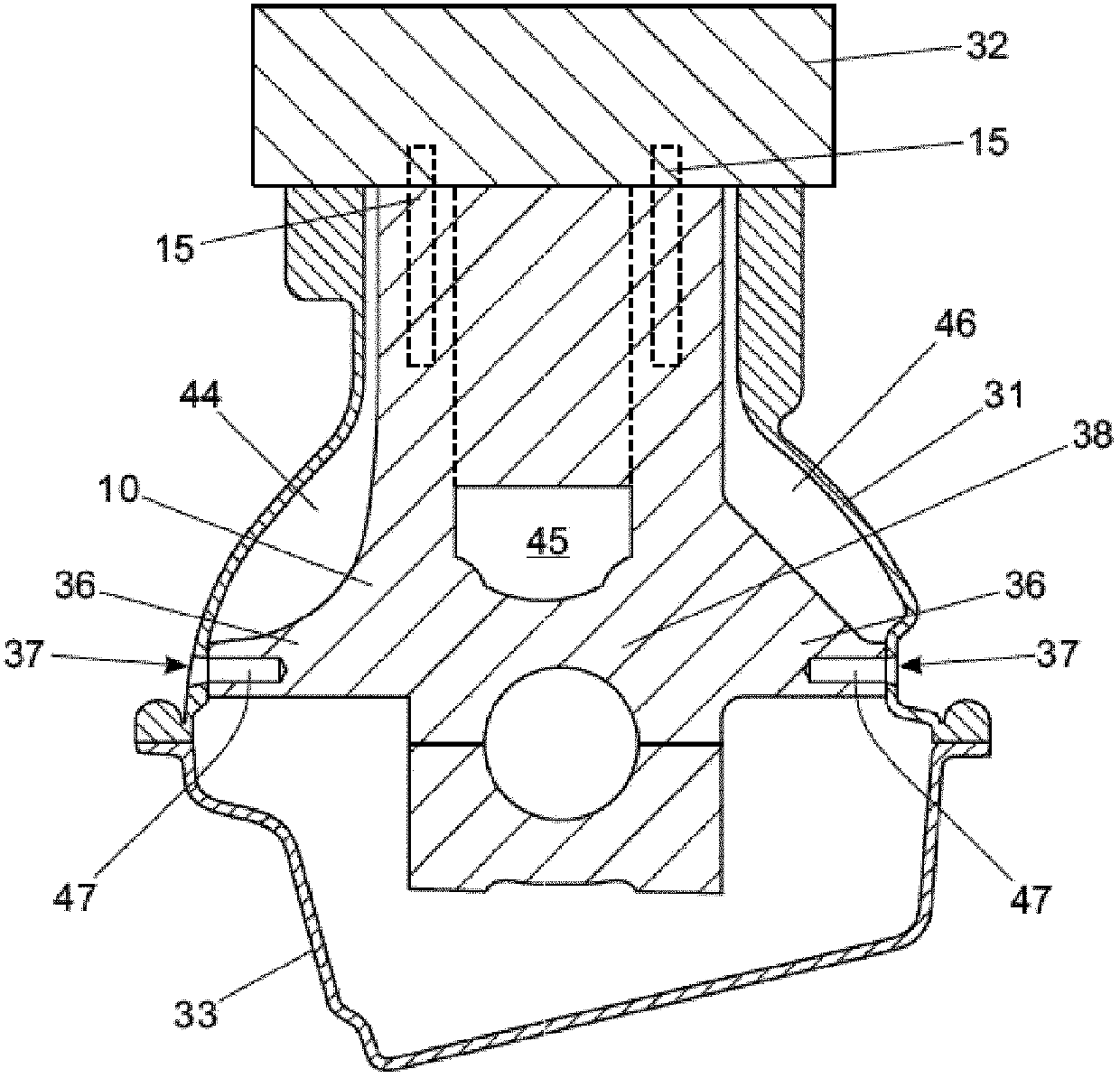

[0066] refer to figure 1 , the internals provided by the monolithic core (10) of an inline four-cylinder engine define cylinders (11) and main bearing housings (12). Typically, main bearings will be provided at either end of the crankshaft and between each cylinder pair, but fewer bearings are possible. The material of the core can be eg aluminum alloy or cast iron.

[0067] In the depicted arrangement, the material content of the core (10) is minimized and thus the struts (13) connect the cylinders (11) and the main bearing housing (12), and stiffening ribs (14) are provided in the area between the cylinders middle. The nature and form of the connecting and reinforcing sections may be optimized by any known method according to the required function, but it should be understood that the inner and outer surfaces of the core are generally accessible for machining. In the illustrated embodiment, the cylinder is provided with an integral coolant passage (15) to be fed via the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com