Waterproof, flame-retarding, antibacterial and anti-ultraviolet printed polyester fabric and manufacturing process thereof

An anti-ultraviolet and polyester technology, which is applied in the direction of synthetic resin layered products, lamination devices, lamination auxiliary operations, etc., can solve the problems that cannot meet the protection needs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

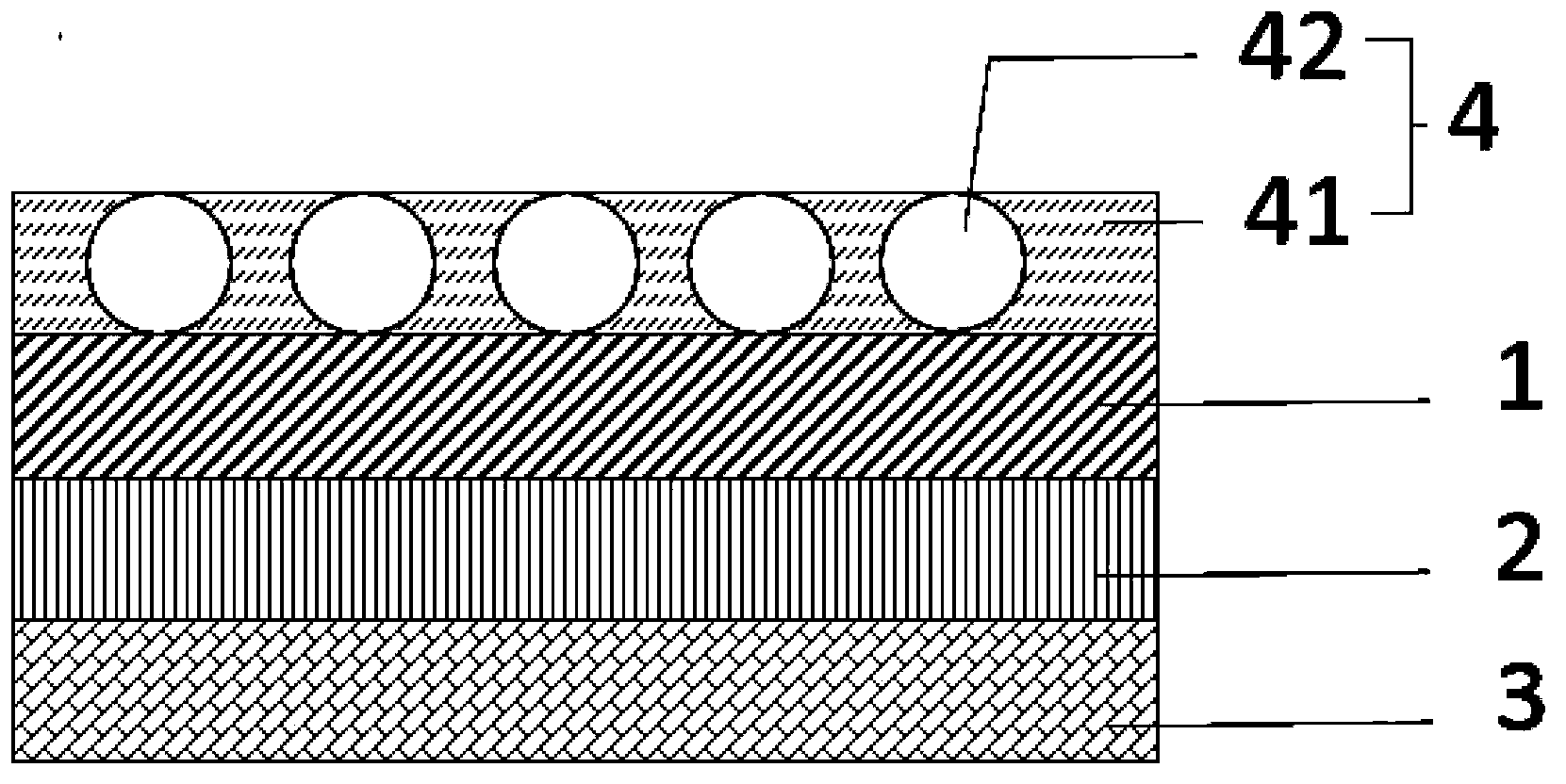

[0016] Such as figure 1 As shown, a waterproof, flame-retardant, antibacterial, anti-ultraviolet printed polyester fabric includes a polyester fabric 1, the front of the polyester fabric is provided with a waterproof layer 2, and the surface of the waterproof layer is provided with a pattern layer 3. The reverse side of the polyester fabric is provided with a flame-retardant layer 41 and an anti-bacterial and anti-ultraviolet layer 42, and the flame-retardant layer and the anti-bacterial and anti-ultraviolet layer are an integral layer 4 of flame-retardant, anti-bacterial and anti-ultraviolet.

Embodiment 2

[0018] A manufacturing process of waterproof, flame-retardant, antibacterial and anti-ultraviolet printed polyester fabric, comprising the following steps:

[0019] a. Perform desizing pretreatment on polyester fabric 1 at 95°C for 15 minutes, and dry the water with a vacuum suction machine;

[0020] b. Add water repellant to the water tank of the setting machine, waterproof and shape the polyester fabric at 180°C, and then shape it at 200°C to form a waterproof layer 2 on the front of the polyester fabric; the waterproof setting temperature is set reasonably so that the waterproof layer can be firmly attached to the polyester On the fabric, the waterproof layer is not easy to wear.

[0021] c. heat transfer printing is carried out on the front side of the polyester fabric, and a pattern layer 3 is formed on the surface of the waterproof layer;

[0022] d. After blending the flame retardant and the antibacterial and anti-ultraviolet agent through the PU coating, coat it on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com