Stepped energy dissipation method and energy dissipater through aerification in pre-positioned aerification tanks

An energy dissipation technology, applied in water conservancy projects, sea area engineering, coastline protection, etc., can solve the problems of weakened energy dissipation, structural cavitation damage, etc., achieve simple structure, convenient construction, and overcome easy cavitation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

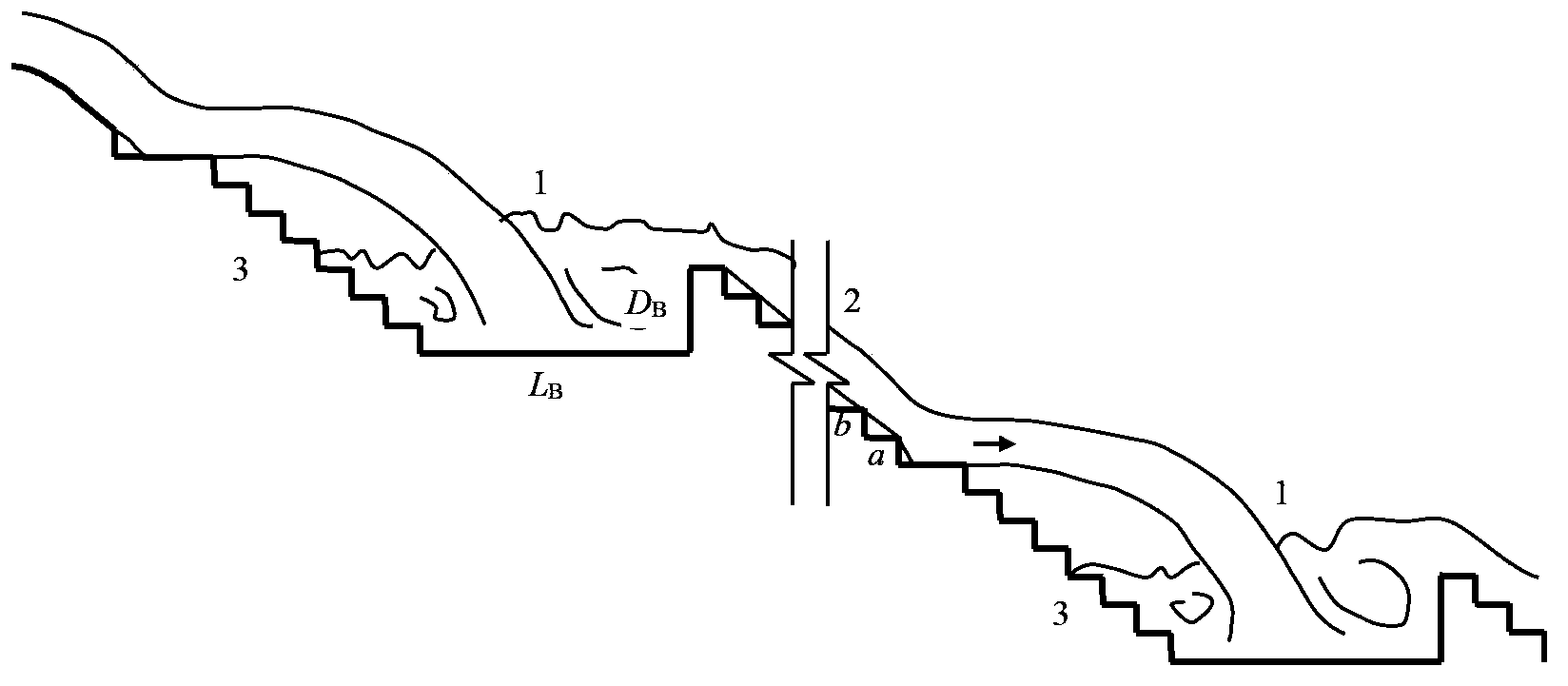

[0030] A step-by-step energy dissipation method for aeration in a pre-aeration pool, for 200m-300m high dam drainage structures, energy dissipation is carried out by stages. Carry out pre-aeration tank aeration and step energy dissipation on the outlet water tongue several times in turn. An aeration vortex is formed in the aeration pool 1 and fully aerated, and then the stepped chute 2 is used to dissipate energy in steps on the fully aerated water flow. In this embodiment, the number of pre-aeration pool aeration and step energy dissipation for the outflow tongue is 2-3 times.

Embodiment 2

[0032] The utility model relates to an energy dissipator for aeration in a pre-aeration pool, and the energy dissipation of 200m-300m high dam drainage structures is completed by classification. It consists of 2-3 levels of energy dissipation sections. In each level of energy dissipation, it includes an aeration tank, a stepped chute, and a pre-step chute connected to the upstream end of the aeration tank. Then, in the next level of energy dissipation, repeat the above structure. In this embodiment, the number of aeration cells is 2-3. The technical solution described in this embodiment can also be expressed as follows, that is: an energy dissipator for aeration in a pre-aeration tank, which is composed of 2-3 energy dissipation sections connected step by step, and the energy dissipation section includes The aeration tank (1), the downstream end of the aeration tank (1) is connected with a stepped discharge chute 2, and the upstream end of the aeration tank 1 is connected wit...

Embodiment 4

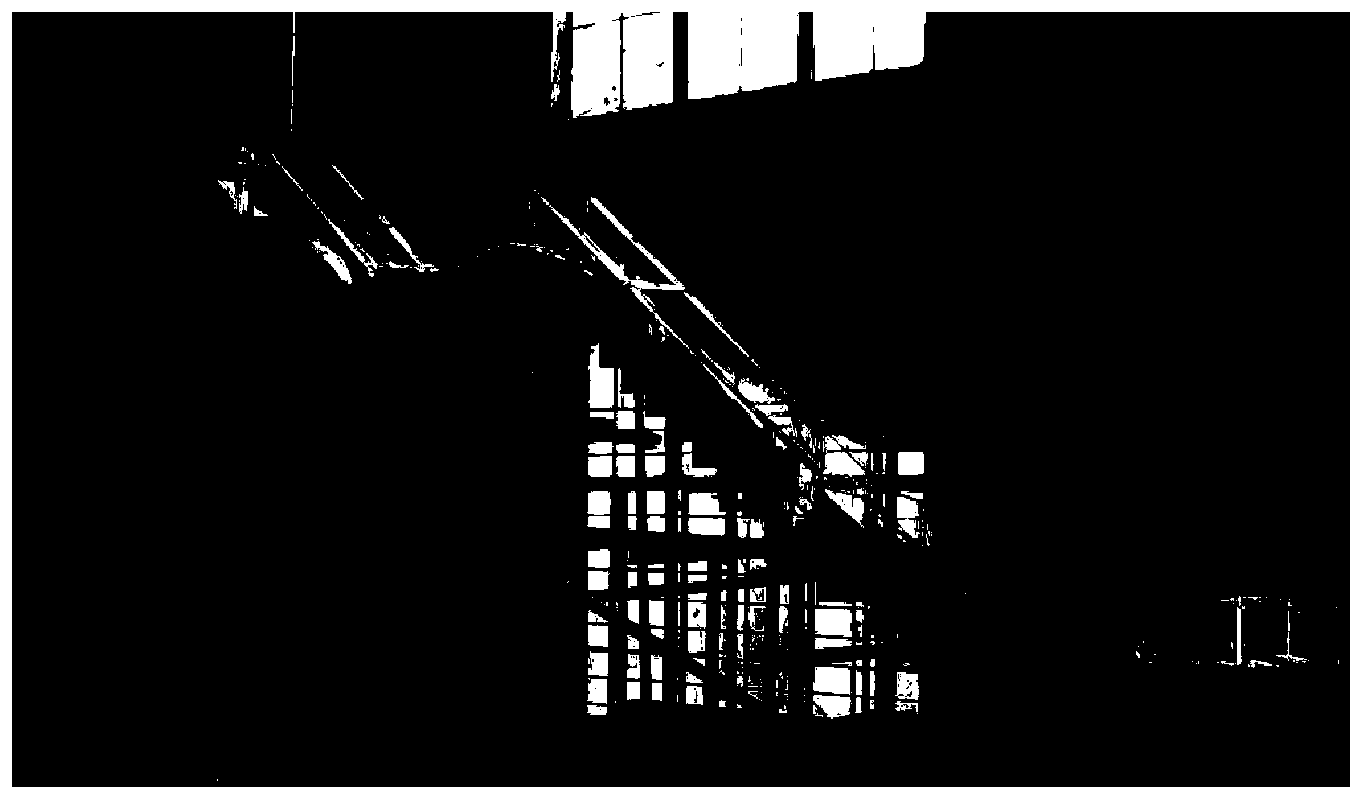

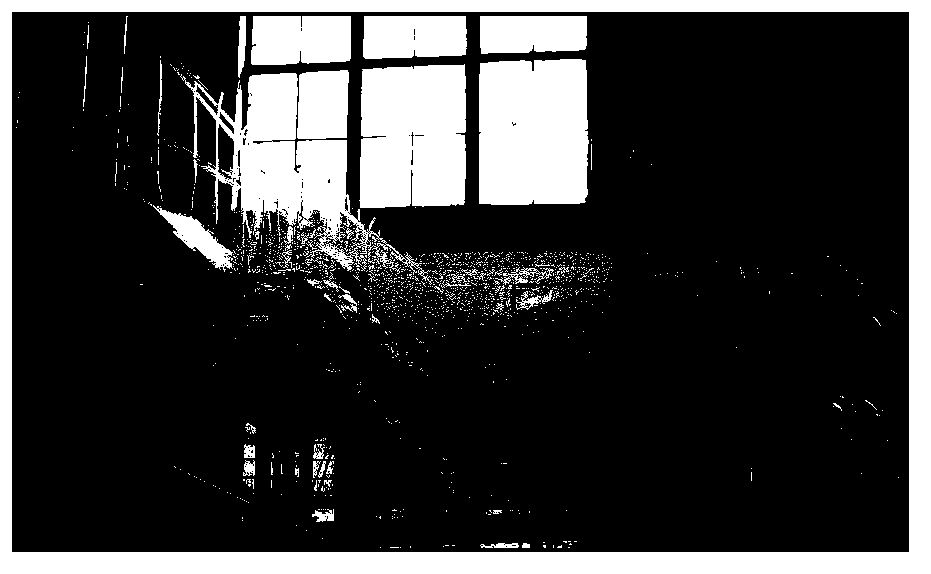

[0039]The test was carried out in the high-speed water flow laboratory of Hohai University. figure 2 It is the photo of the physical model of the test device system and the stepped energy dissipator with aeration in the pre-aeration tank. The test device system includes: water pump motor, water inlet pipe, horizontal water supply tower, model working section, and return water system. The working section of the model is composed of the inlet section of the WES weir and the stepped energy dissipator of the two-stage pre-aeration pool aeration, which is made of plexiglass; the model is designed according to the principle of gravity similarity, and is designed on a scale of 1 / 40 of a certain project. The function of the inlet section is to provide a stable incoming flow and the kinetic energy of the outlet water tongue under the designed single-width flow rate; in the step energy dissipation of each stage of pre-aeration pool aeration, the step horizontal length a=0.09cm, height b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com