Dot-matrix type heat conduction temperature measurement nondestructive crack detection method

A crack detection and heat conduction technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of difficult and accurate detection of superficial micro-cracks, and achieve the effect of simple and intuitive detection methods and intuitive and accurate detection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0036] Specific embodiment one: the non-destructive crack detection method of lattice heat conduction temperature measurement of the present embodiment comprises the following steps:

[0037] (1) Divide the entire surface of the workpiece to be measured into n lattices to be measured according to the X-Y coordinates.

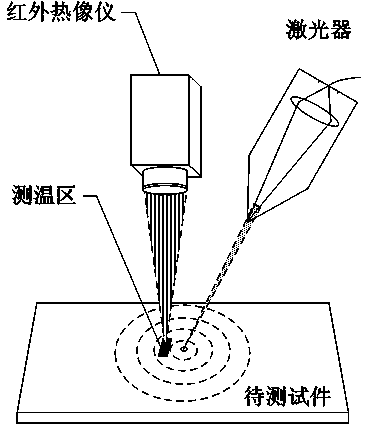

[0038] (2) Set up a laser and an infrared thermal imager above the dot matrix to be measured, irradiate the laser beam with the set power on the surface of the workpiece to be tested, and use the infrared thermal imager to detect the surface of the workpiece to be tested at a distance of 1-10mm from the laser spot in real time The temperature rise curve, detect its highest value.

[0039] The material and surface roughness of the workpiece affect the absorption rate of the laser. The key to this detection method is to rapidly increase the temperature of the irradiation point of the workpiece by tens of degrees to one or two hundred degrees, that is, the gen...

specific Embodiment approach 2

[0046] Specific implementation mode two: the non-destructive crack detection method of lattice heat conduction temperature measurement of the present embodiment comprises the following steps:

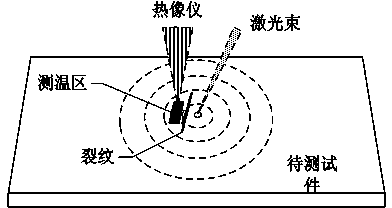

[0047] Such as figure 1 As shown, a laser and an infrared thermal imager are installed above the test piece; a beam of laser with a set power is irradiated on the test piece for t1 seconds; at the same time, an infrared thermal imager is used to detect a laser spot at a distance of L=1mm. Set the temperature rise curve of the temperature measurement area (generally within a few square mm, and keep the L distance and the area of the set area unchanged) during the entire detection process, and detect the highest value.

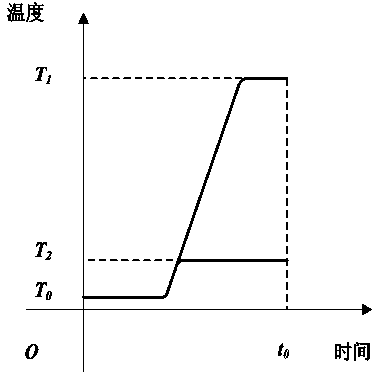

[0048] When there is no crack between the laser spot and the detection area, the heat conduction is good, and the temperature rise is very high; when there is a crack between the laser spot and the detection area, the maximum value of the measured temperature rise is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com