Ultrasonic waveguide provided with cooling system

A cooling system and ultrasonic technology, applied in ultrasonic therapy, treatment and other directions, can solve the problems of difficult operation, affecting the effect and stability of the equipment, and high use cost, to reduce the use cost, avoid overheating damage, and improve the use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

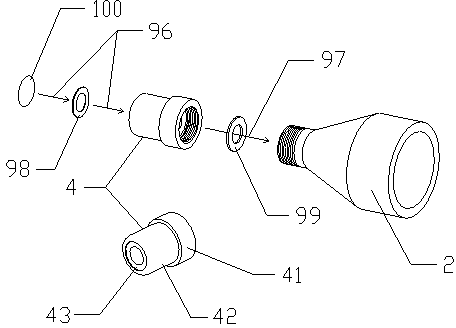

[0053] The specific plan of the waveguide cap:

[0054] As shown in Figure 1(c). The waveguide cap is made of nylon. The upper connector of the waveguide cap is a metric M20 internal thread, the top of the lower part of the ultrasonic waveguide housing is an M20 external thread, and the two are connected by a thread 97 fastening 97. A rubber gasket 99 is used for sealing between the waveguide cap and the ultrasonic shell. The conductive film 100 adopts a polyurethane thin film sheet. The prefabricated polyurethane film is circular, and the polyurethane film is bonded and fixed on the sealing ring 98 through epoxy resin 96, and the sealing ring is bonded and fixed on the conductive film base 43 at the lower end of the waveguide cap through epoxy resin 96.

[0055] The waveguide cap model and working parameters are marked on the side of the waveguide cap, such as "CAP-02A-201515 500k / 12 / 06 / P34 / T40". The model number is "CAP-02A-201515", "CAP" indicates that the component is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com