Ordinary intermediate frequency forging heating furnace for non-oxidation technical transformation process

A forging heating and intermediate frequency technology, which is applied in the forging industry and the field of intermediate frequency furnace heating, can solve the problems of increasing billet making process and preliminary forging process, reducing the service life of forging dies, and cost pressure of gear precision forging enterprises, so as to improve product quality, The effect of reducing resistance and improving material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to clearly describe the specific implementation and facilitate the implementation of this patented technology, all parts and components in all drawings are listed in the order of serial numbers as follows:

[0045]

[0046]

[0047]

[0048] The specific implementation is described in detail as follows with reference to the drawings:

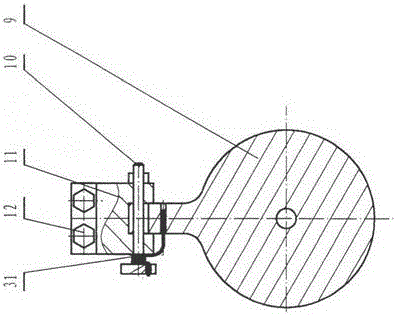

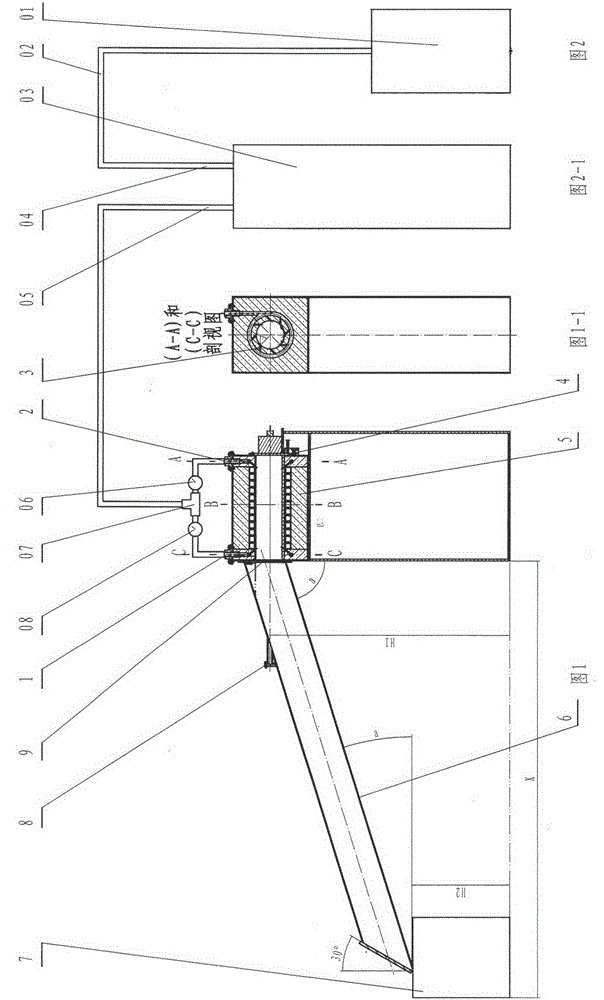

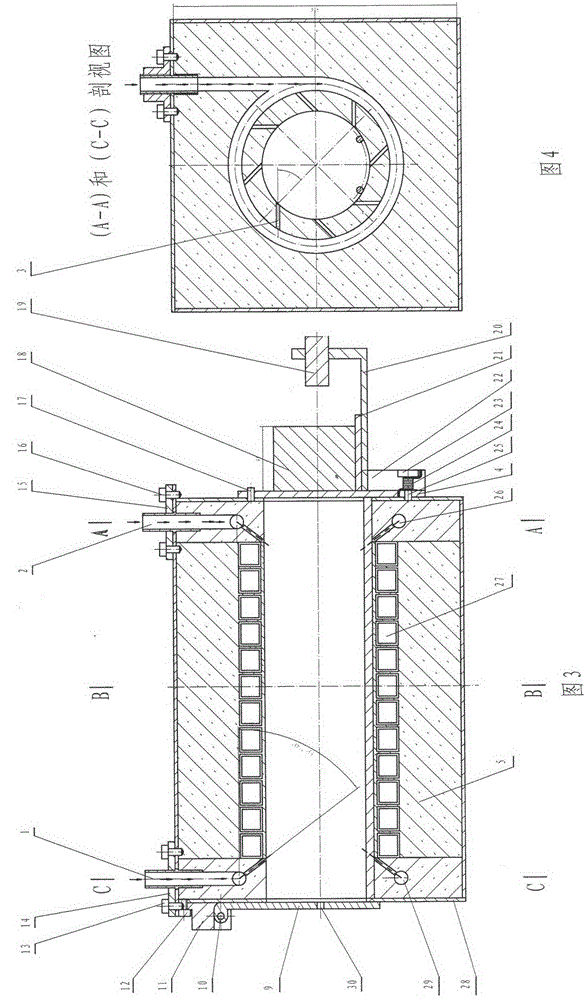

[0049] figure 1 It is the overall structure diagram of the ordinary intermediate frequency forging heating furnace without oxidation technology transformation. (01) is a nitrogen generator, the nitrogen generator nitrogen outlet (02) of the nitrogen generator is fixedly connected with the nitrogen storage tank inlet (04) of the nitrogen storage tank (03), and the nitrogen storage tank of the nitrogen storage tank (03) The air outlet (05) is fixedly connected with the three-way pipe joint (07), the second inlet pressure gauge (06) of the furnace is connected with the second inlet, that is, the inlet of the furnace feeding end, the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com