Machine workshop task scheduling energy-saving optimization system based on reinforcement learning

A technology of machine workshop and reinforcement learning, applied in the field of energy saving optimization scheduling and energy consumption of machinery manufacturing industry, can solve the problem of insufficient energy saving and consumption reduction in the workshop, and achieve the effect of reducing energy consumption, low computational complexity and easy expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

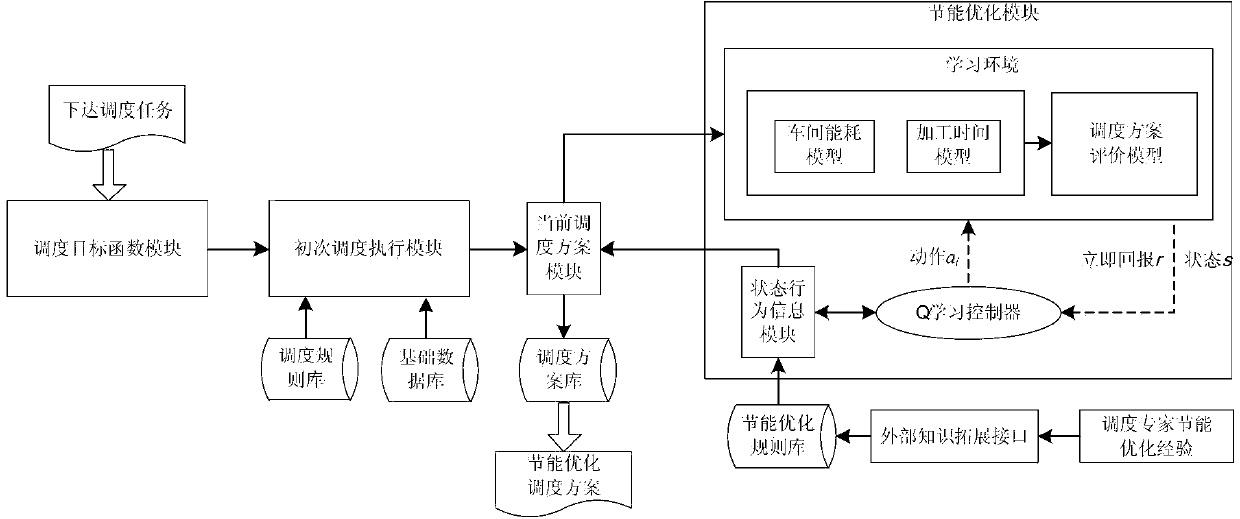

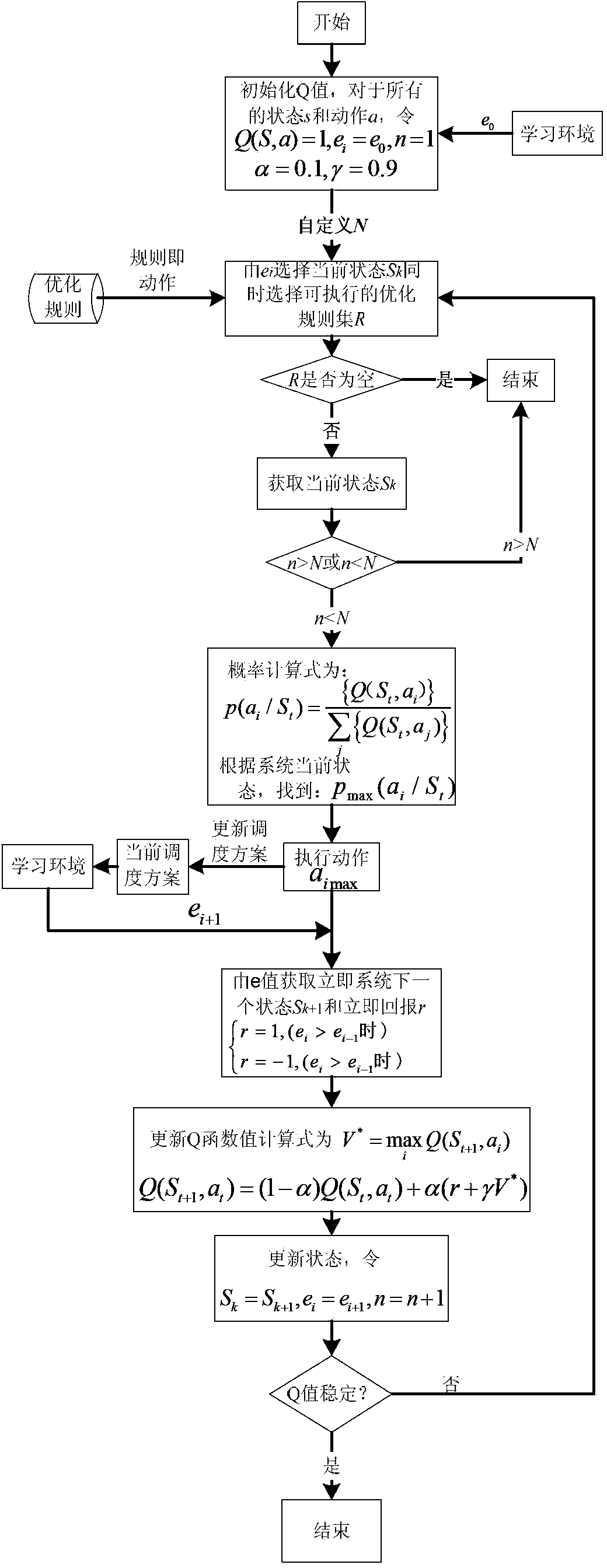

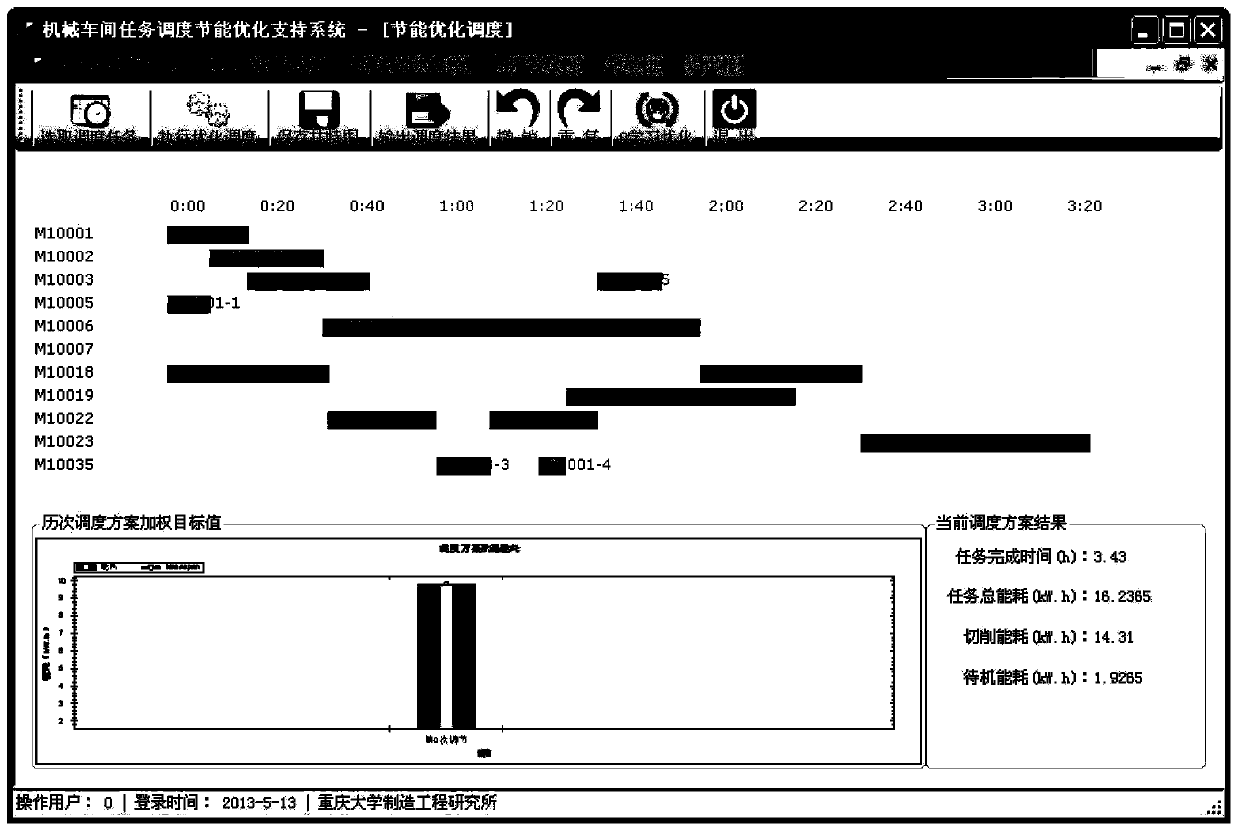

[0086] An energy-saving optimization support system for task scheduling in mechanical workshops based on reinforcement learning. This system is used to optimize energy-saving scheduling for a workshop scheduling task. The process is as follows:

[0087] The standby power information of machine tools owned by a workshop is shown in Table 2:

[0088] Table 2 Standby power of workshop machine tools

[0089]

[0090] There are currently a batch of processing tasks consisting of three workpieces. The historical statistical information of the processing machine tools, processing time and processing energy consumption of all processes of each workpiece is shown in Table 3:

[0091] Table 3 Each process of the workpiece corresponds to the processing machine tool, processing time (h) and processing energy consumption (kW.h)

[0092]

[0093]

[0094] Store the machine tool standby power information in Table 2 below and the task processing information in Table 3 into the basic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com