Self-rheostat-starting wound rotor electric motor device

A wound rotor and motor technology, applied in electromechanical devices, asynchronous induction motors, starters of a single DC motor, etc., can solve problems such as needs, and achieve the effect of good integration and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

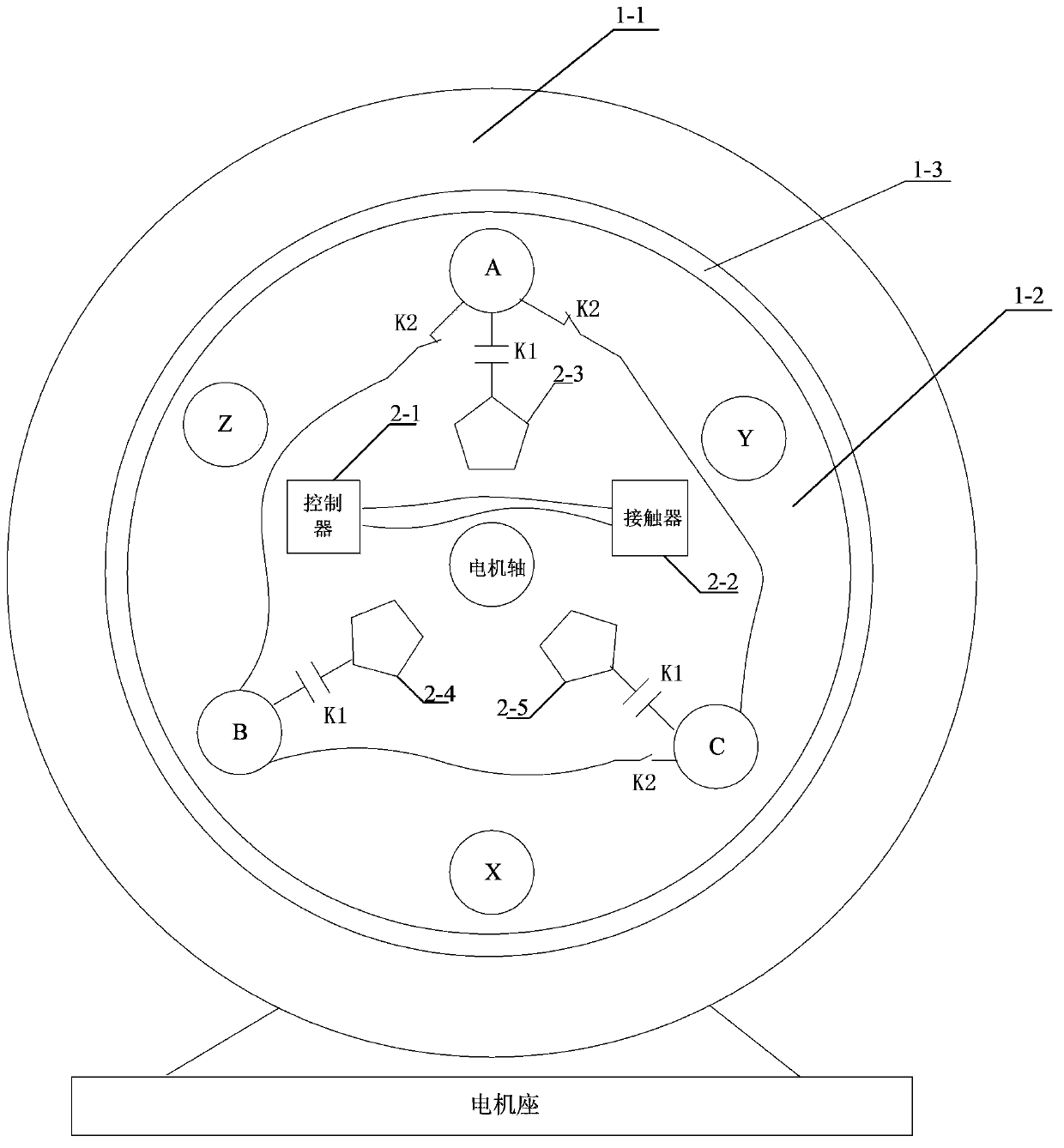

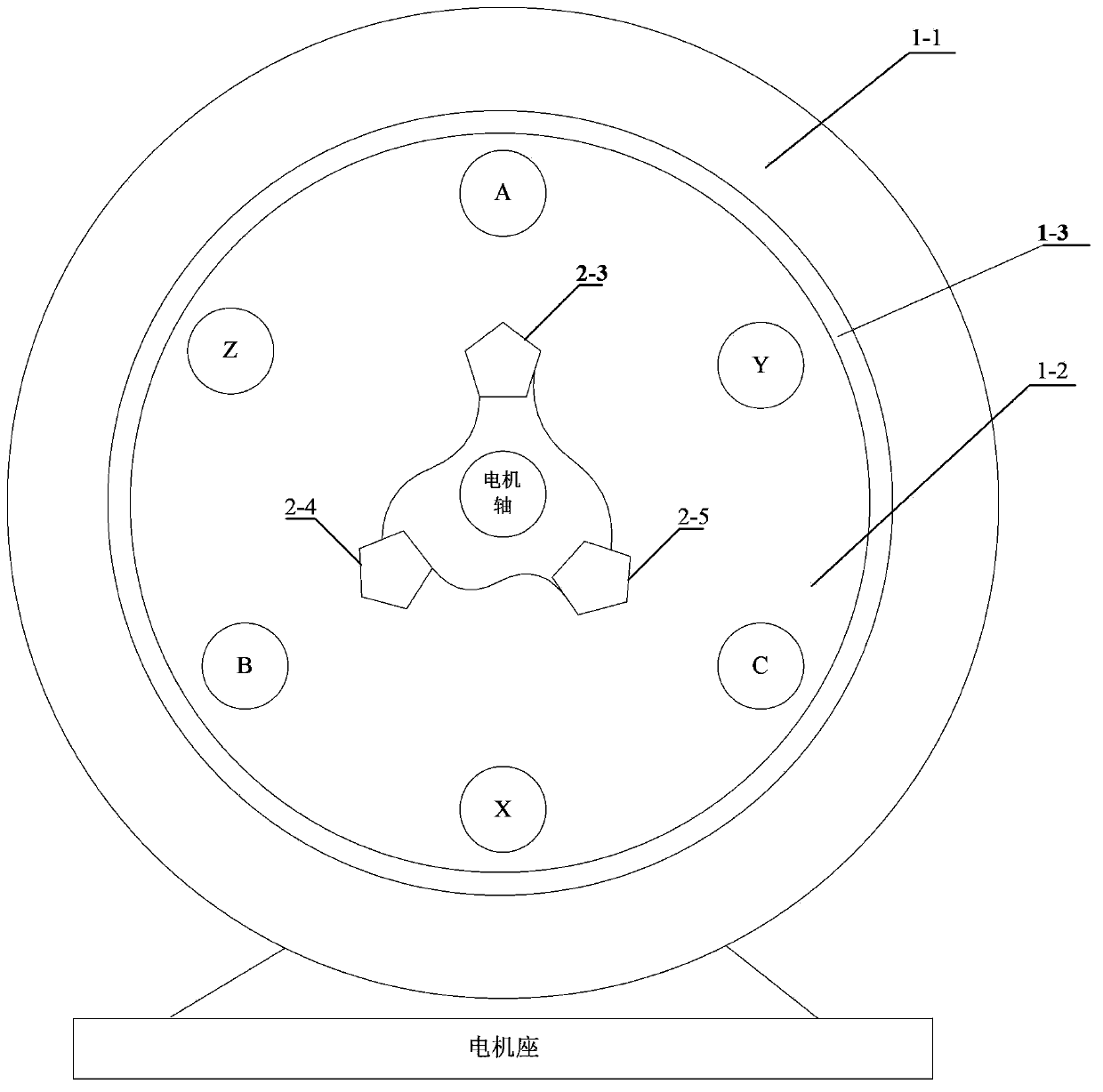

[0008] Specific implementation mode one: combine figure 1 , figure 2 , image 3 with Figure 4 Describe this embodiment, the motor device for starting a wound rotor from a variable resistance described in this embodiment, it includes a wound rotor motor 1, the rotor core 1-2 is coaxially set in the inner cavity of the stator 1-1, and the rotor There is an air gap 1-3 between the outer surface of the iron core 1-2 and the inner surface of the stator 1-1, and the three-phase windings are correspondingly wound around the outer surface of the rotor iron core 1-2, and the three-phase windings are respectively AX and BY And CZ, it also includes controller 2-1, contactor 2-2, No. 1 resistor 2-3, No. 2 resistor 2-4, No. 3 resistor 2-5 and generator speed sensor S, controller 2-1, contactor 2-2, No. 1 resistor 2-3, No. 2 resistor 2-4, No. 3 resistor 2-5 and generator speed sensor S are all placed in the inner cavity of rotor core 1-2 Among them, one end of the No. 1 resistor 2-3 i...

specific Embodiment approach 2

[0013] Specific embodiment 2: This embodiment is a further limitation of the motor device for starting the wound rotor from the rheostat described in specific embodiment 1. The generator speed measuring sensor S adopts a ZCF121 sensor.

specific Embodiment approach 3

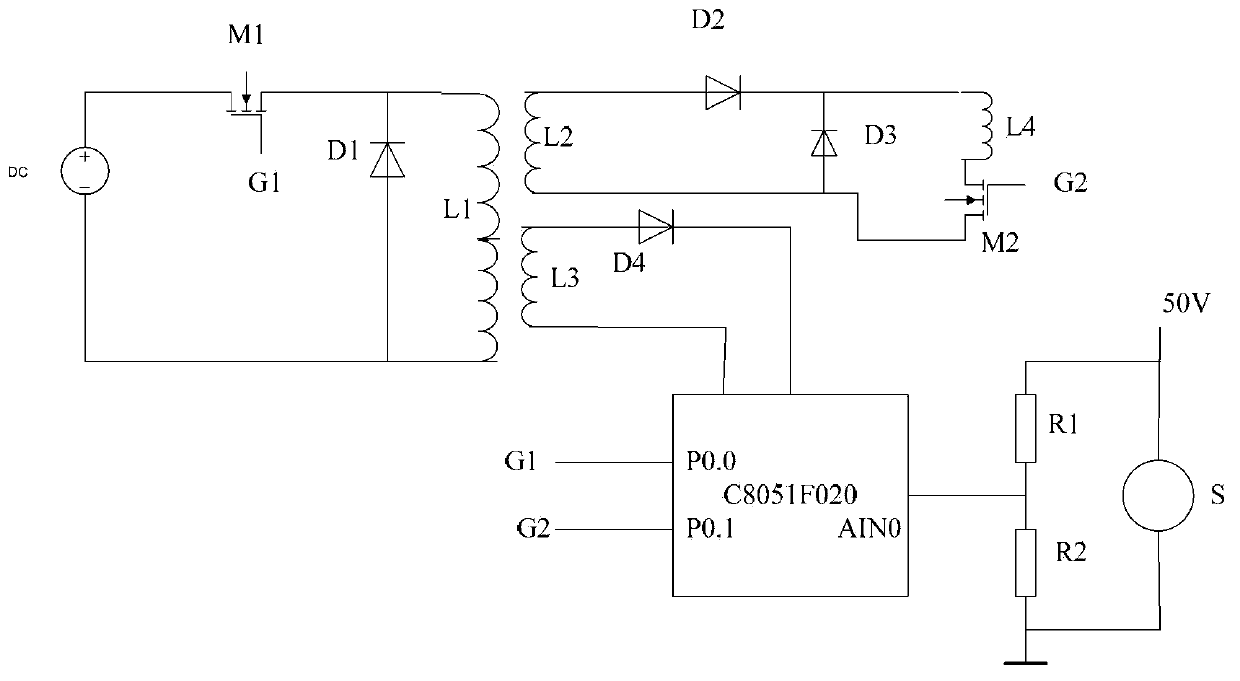

[0014] Specific implementation mode three: combination image 3 This embodiment is described. This embodiment is a further limitation of the motor device for starting a wound rotor with a self-varistor described in Embodiment 1. The controller 2-1 adopts a C8051F020 single-chip microcomputer.

[0015] For the block diagram of the control flow of the single-chip microcomputer, see Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com