Tobacco shred feeding treatment device and method capable of improving the heat energy and feed liquid absorption efficiency of tobacco shred

By adjusting the position and angle of the air inlet pipe in the cut tobacco feeding and processing device, combined with condensed water collection and temperature detection, the problem of insufficient heat exchange between steam and cut tobacco is solved, achieving high efficiency and uniformity of heat energy absorption by cut tobacco and material liquid, and reducing the cost Energy consumption and pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

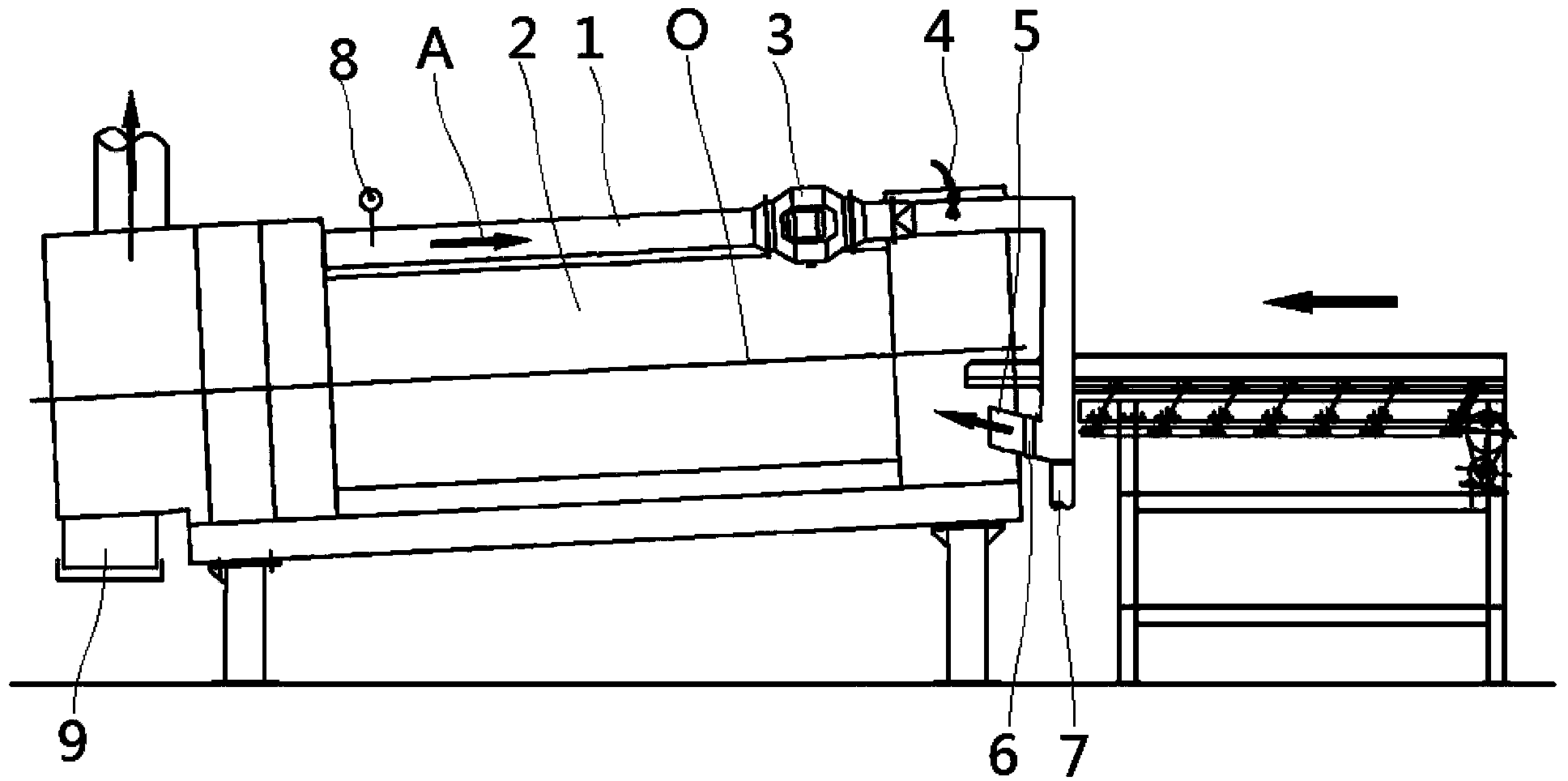

[0027] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

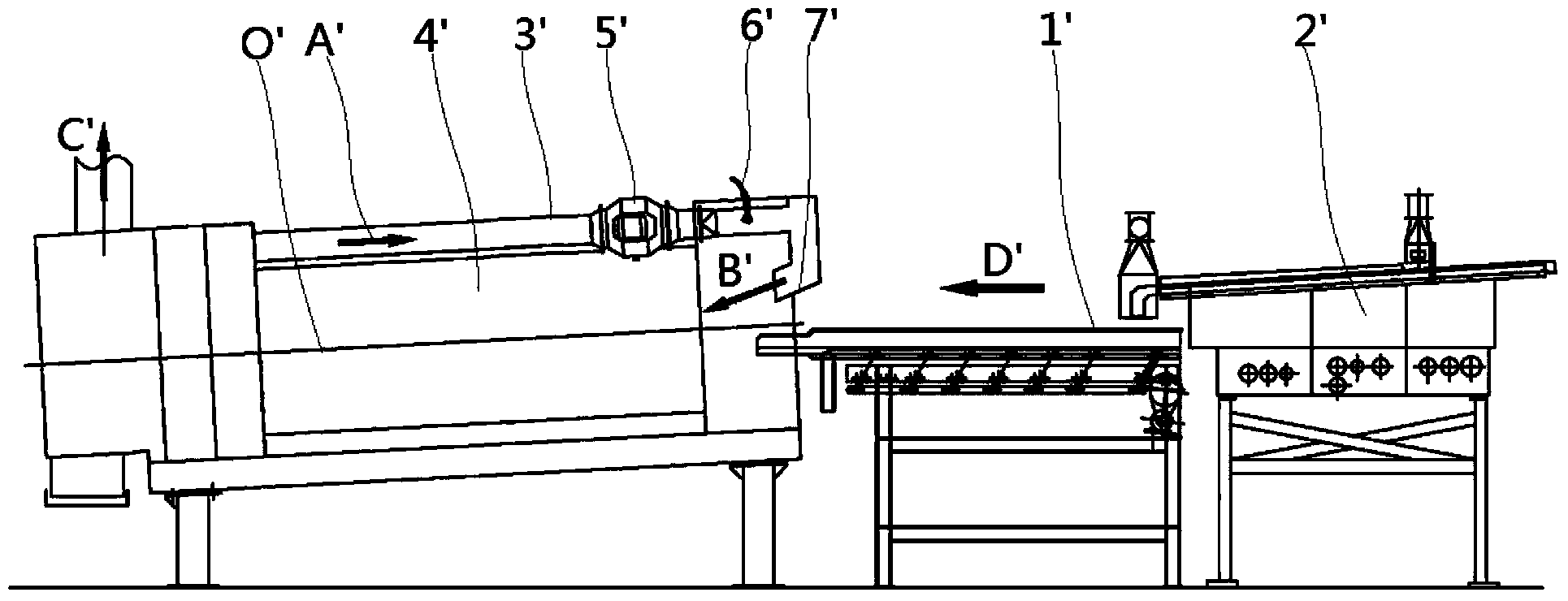

[0028] Such as figure 2 Shown, the shredded tobacco feeding treatment device that the present invention provides to improve shredded tobacco absorption heat energy and feed liquid efficiency comprises shredded tobacco feeder and vibrating tank, the feeding end of shredded tobacco feeder ( figure 2 The right end of the shown shredded tobacco feeder) does not need to be equipped with warming and humidifying equipment, because the warming and humidifying equipment is a kind of shredded equipment with high energy consumption and serious environmental pollution, and its daily cleaning and maintenance workload is large, so The invention not only reduces energy consumption and environmental pollution, but also reduces equipment investment and daily operation and maintenance costs.

[0029] The same as the prior art is: the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com