Rotating drum-type particle counting machine

A granulator and drum type technology, applied in the field of rotary drum granulator, can solve the problems that affect the production volume and qualified bottling rate of the enterprise, the counting speed of the granulator is slow, and the material particles are rubbed and dusted. The effect of uniform filling count beat, fast sieving speed and fast filling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

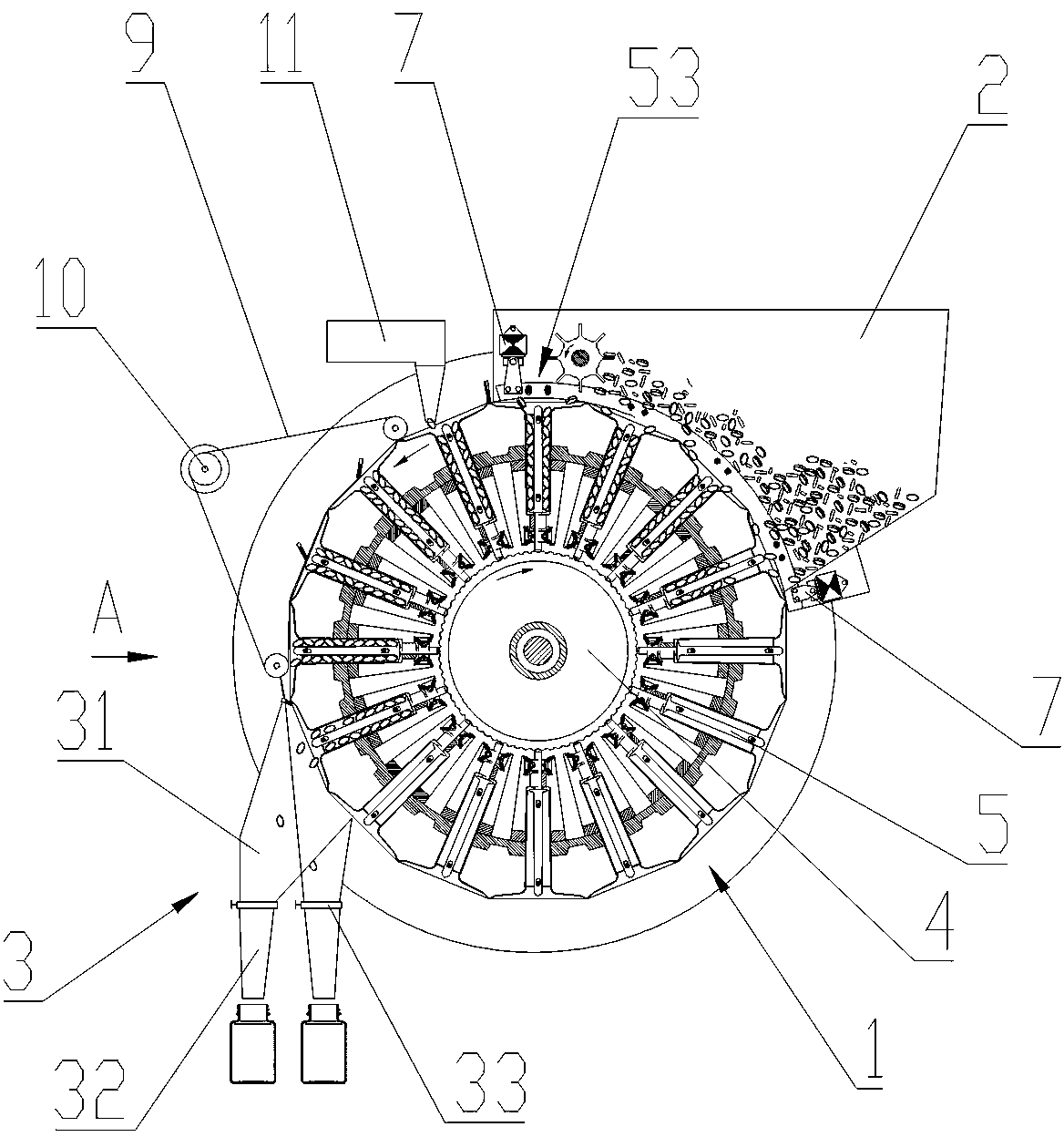

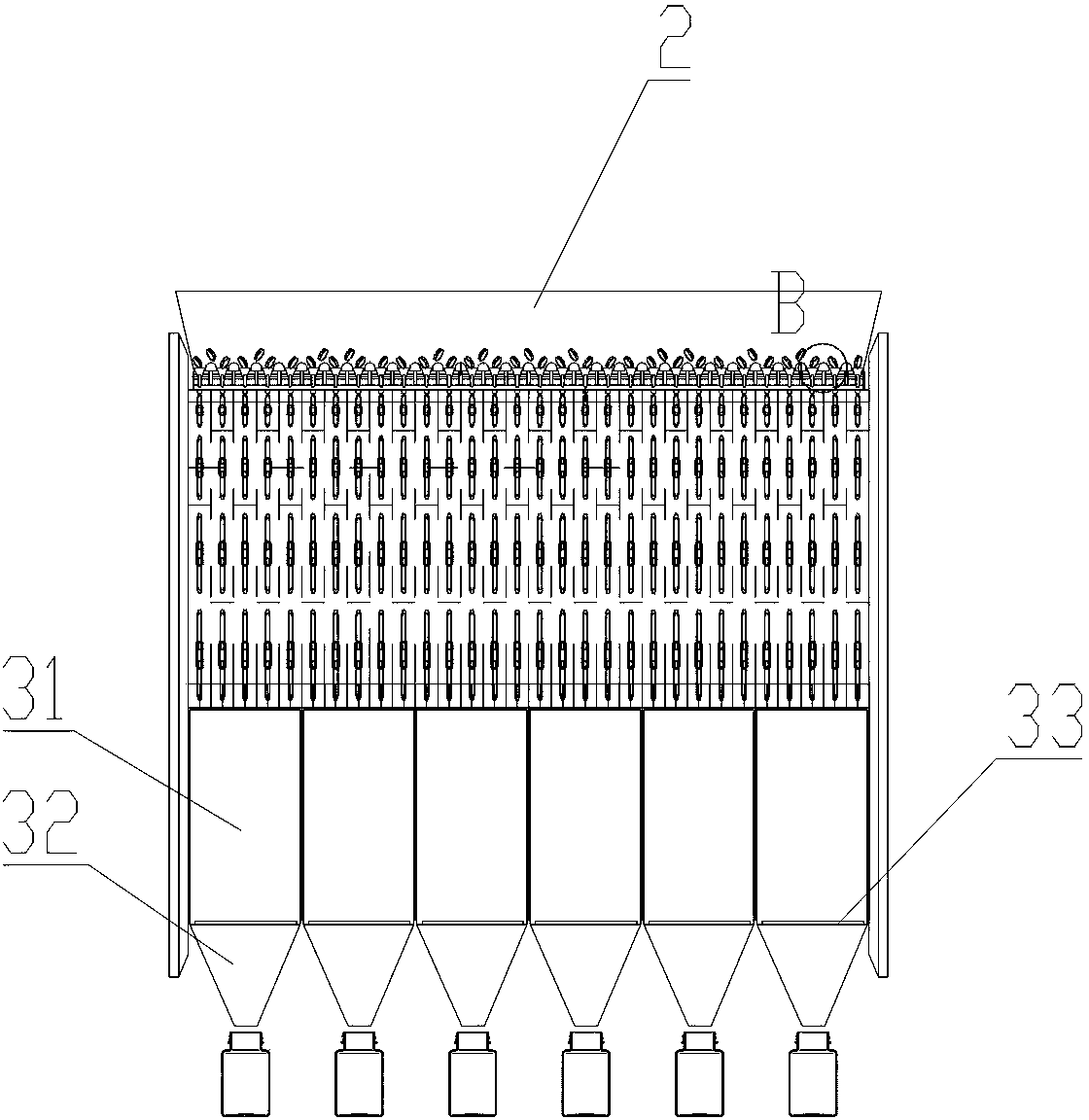

[0025] Drum counting machines, such as figure 1 , 2 As shown, it includes a counting wheel 1, a storage bin 2, and a collector 3, wherein the counting wheel 1 is a polygonal wheel with a central axis placed horizontally, and a corrugated roller 4 is coaxially arranged inside the counting wheel 1. The corrugated roller 4 rotates in the opposite direction relative to the counting wheel 1 , and through additional speed regulation, the rotational speed of the corrugated roller 4 relative to the counting wheel 1 can be controlled, thereby changing the vibration frequency of the counting bin 5 .

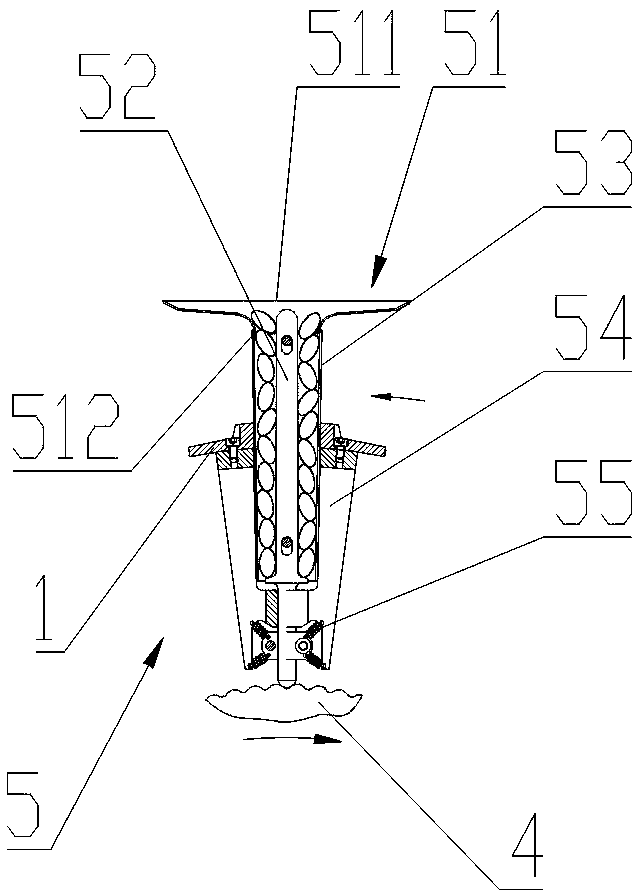

[0026] The counting bins 5 are evenly distributed on the circumference of the counting wheel 1, the counting bins 5 are arranged along the radial direction of the counting wheel 1, and the corrugated rollers 4 are evenly distributed with protrusions. The detailed structure of the counting bin 5 is as follows: image 3 As shown, it includes an inlet mouthpiece 51, a vibrating rod 52, a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com