Waste rubber desulfurization plasticizing device

A technology of waste rubber and heating device, which is applied in the direction of plastic recycling and recycling technology, can solve the problems of uneven quality fluctuation of desulfurization rubber, uneven mixing of tank walls, and easy blocking of materials and sticking spiral. The effect of equipment use safety, solving environmental pollution problems, and high quality of recycled rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

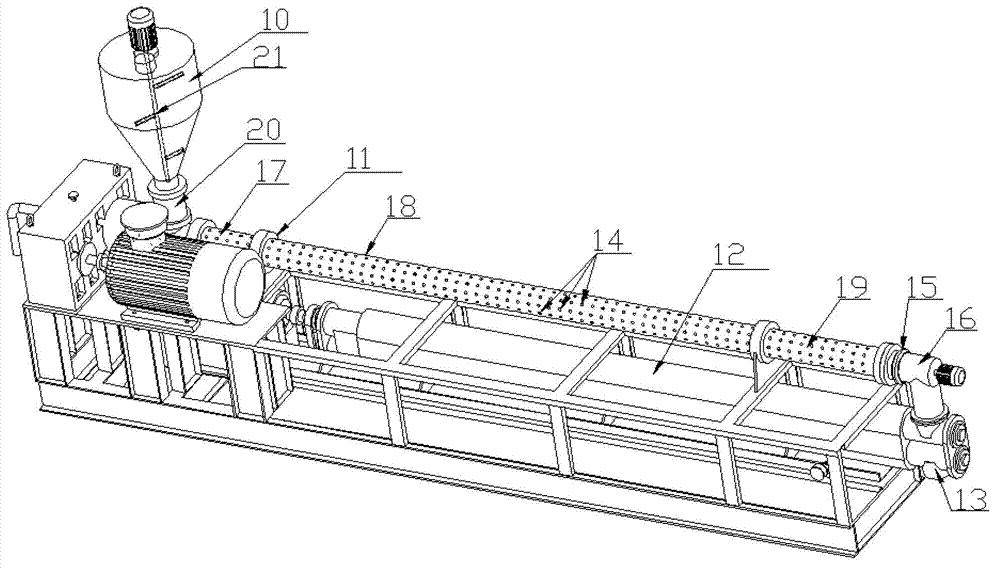

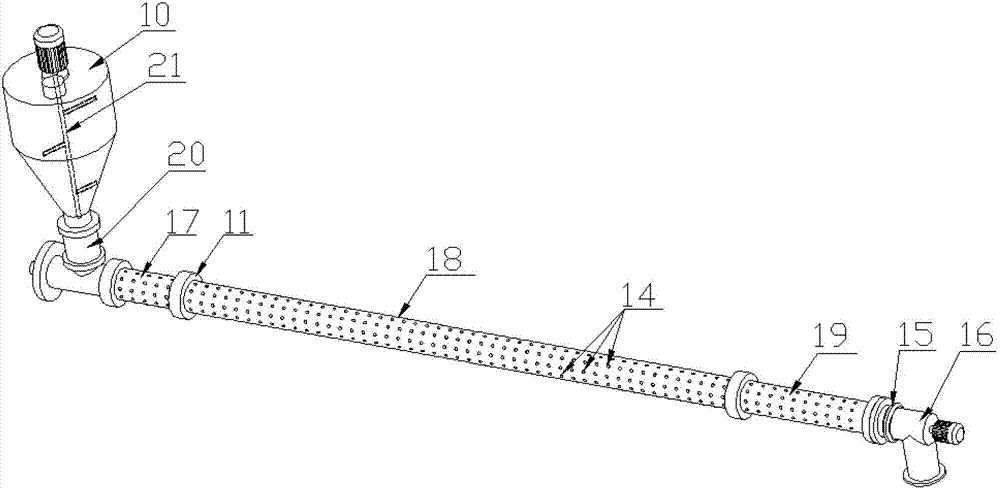

[0016] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —2: waste rubber desulfurization and plasticization device, including a storage bin 10, the storage bin 10 is connected to the plasticizing pipeline 11, the end of the plasticizing pipeline 11 is connected to the cooling pipeline 12, the discharge port 13 is arranged at the end of the cooling pipeline 12, and the plasticizing pipeline 11 and the cooling pipe 12 are fed in a spiral manner, and the surface of the plasticizing pipe 11 is provided with a heating device, wherein, the inner wall of the plasticizing pipe 11 is uniformly provided with pins 14, so that the rubber powder is effectively pounded evenly during the conveying process. , the desulfurization and plasticization are more sufficient, and it can prevent the rubber powder from being charred or adhered due to uneven heating. The end of the plasticizing pipeline 11 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com