Protection device for sealing working face of petroleum downhole tool

A technology for protection devices and working surfaces, which is applied in the directions of packaging, transportation, packaging, closing, etc., can solve the problems of high mold maintenance costs, waste of resources, unfavorable environmental protection, etc., to solve the problem of environmental pollution, simple replacement of corrosion-resistant surfaces, and reduce The effect of wasting resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

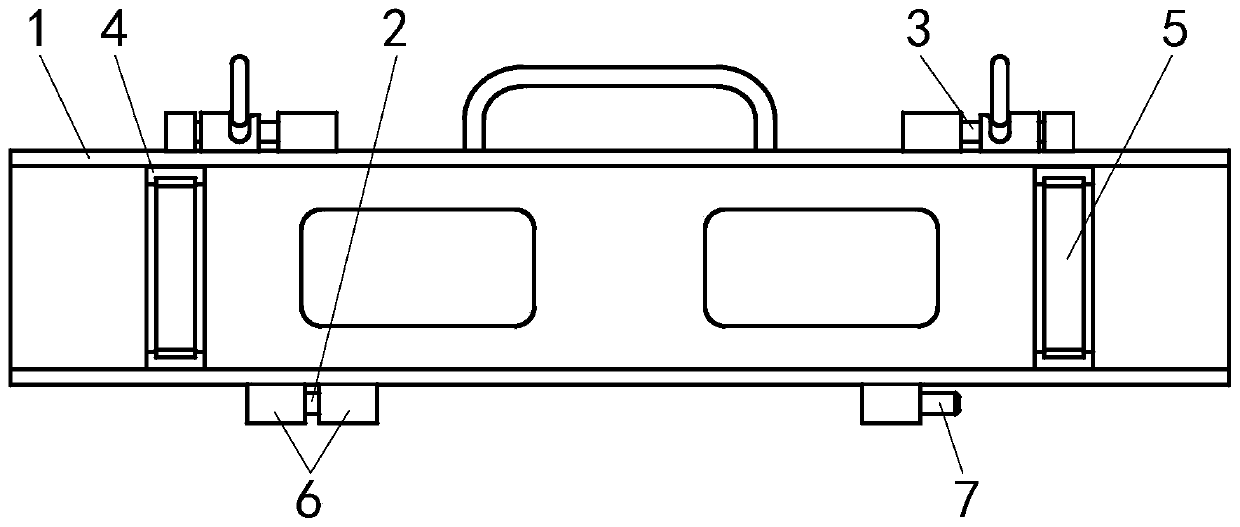

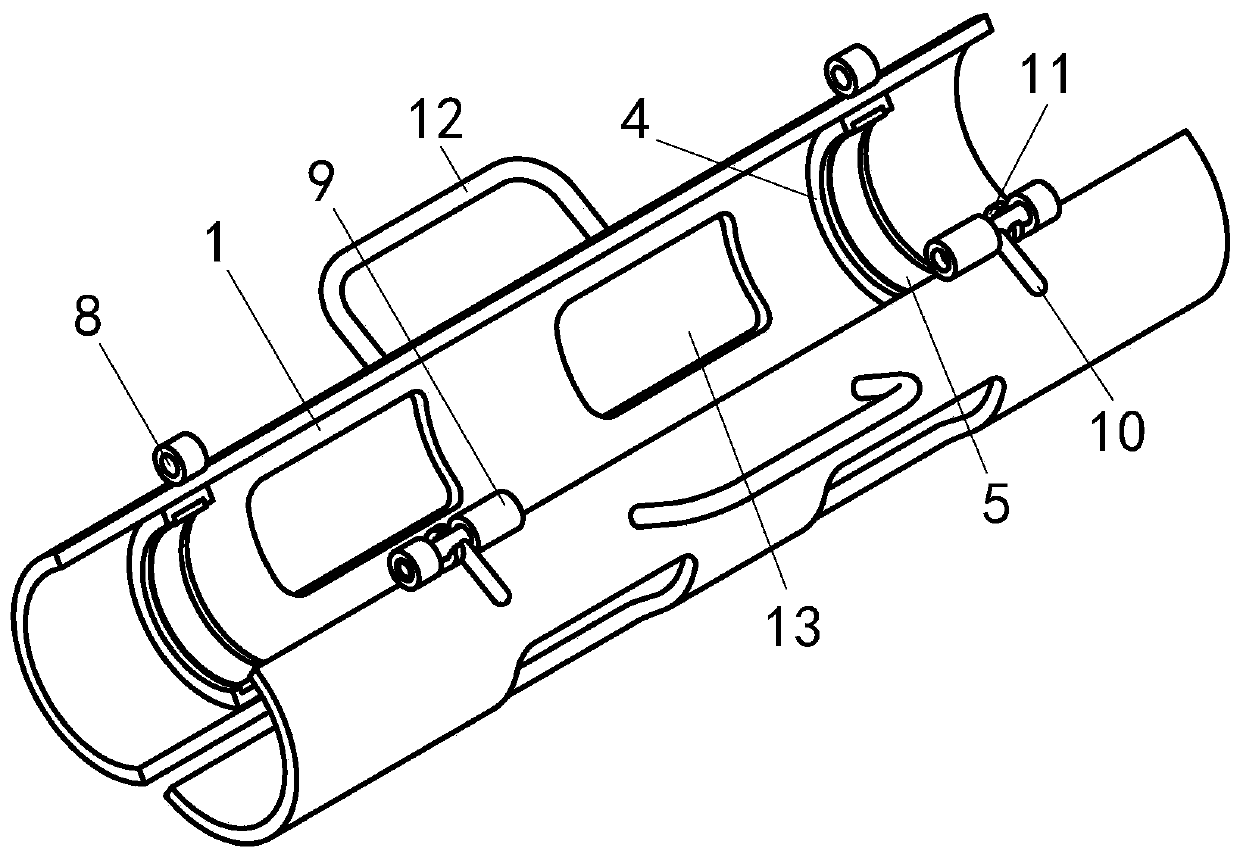

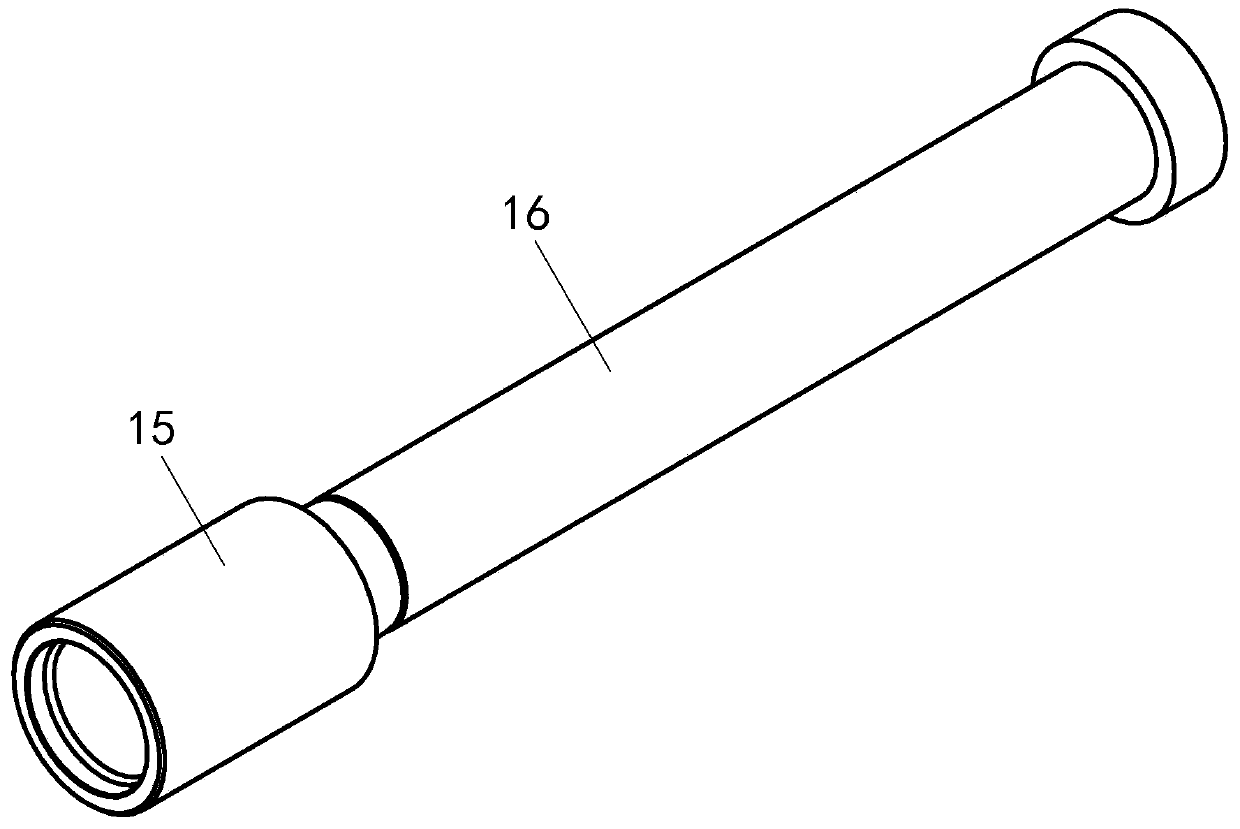

[0021] A protection device for the sealing face of an oil well tool of the present invention, such as figure 1 and figure 2 As shown, it includes a pair of clamp body 1; the shape of the clamp body 1 is tile-like; a pair of clamp body 1 synthesizes a cylindrical clamp; 2 Hinged, the other side of a pair of clamp bodies 1 is quickly connected by a pair of latch devices 3; the inner arc surface of the clamp body 1 is provided with a support half ring 4; the inner ring surface of the support half ring 4 is provided with a rubber Pad 5. A pair of hinge devices 2 are symmetrically welded on one side of a pair of clamp bodies 1; the hinge device 2 includes a pair of respin sleeves 6, which are round tubular; one of the resell sleeves 6 is connected to the left clamp body 1 side welding; another repin sleeve 6 is welded to the side of the clamp b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com