Step type aluminum alloy node device and assembling method thereof

An aluminum alloy, stepped technology, applied in construction, building structure, construction material processing and other directions, can solve the problems of high maintenance cost, bulky structure, poor permeability, etc., achieve simple construction process, good corrosion resistance, good permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

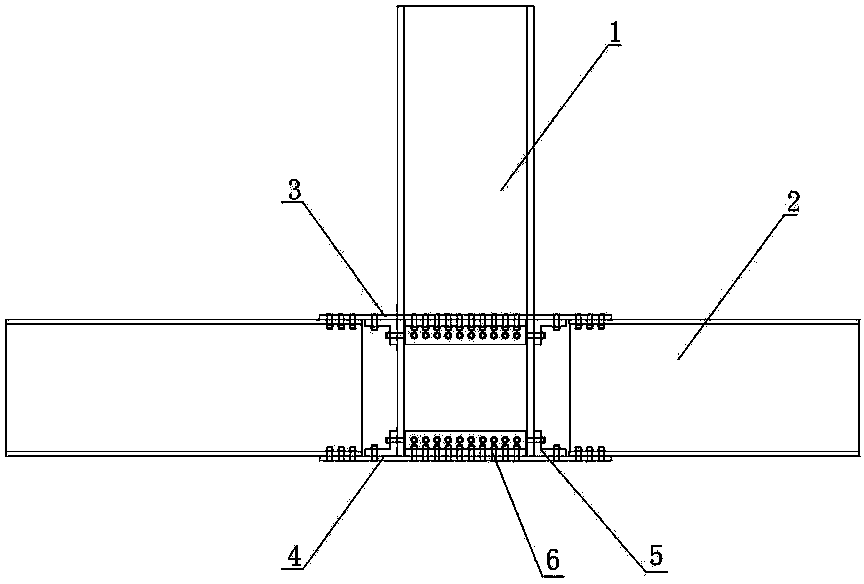

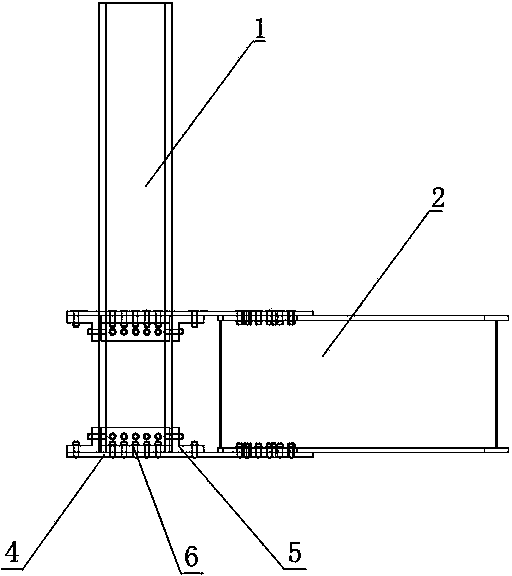

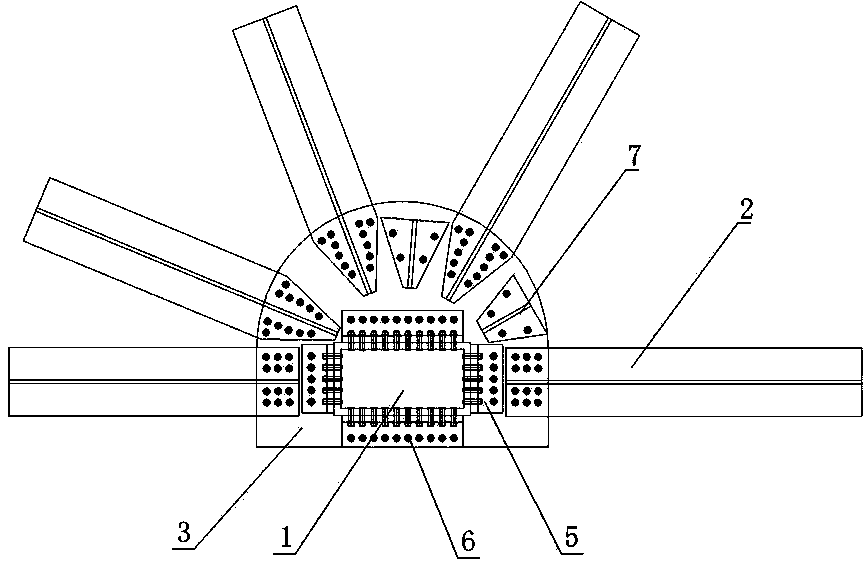

[0023] Embodiment: The stepped aluminum alloy node device of this embodiment is as follows figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes fixedly connected vertical rods 1 and a group of horizontal rods 2. A group of horizontal rods 2 is distributed in the center of the vertical rod 1. Between the vertical rods 2 and the horizontal rods 1 The opposite first disc body 3 and the second disc body 4 are connected, the first disc body 3 is provided with a via hole for passing through the vertical rod 1, the side wall at the end of the vertical rod 1 is connected with the first disc L-shaped connectors 5 are connected between the opposite side surfaces of the body 3 and the second disc body 4, and the top and bottom surfaces of the ends of the horizontal bars 2 are respectively connected to the opposite sides of the first disc body 3 and the second disc body 4. The sides are fixedly connected, and an I-shaped support plate 7 is fixedly connected between the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com