GFRP light prefabricated assembly type cable duct bank and construction method thereof

A technology for cable ducting and prefabrication, which is used in cable installation, cable laying equipment, cable installation in underground pipes, etc., can solve the problems of reducing on-site construction efficiency, low degree of automation, and heavy component weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

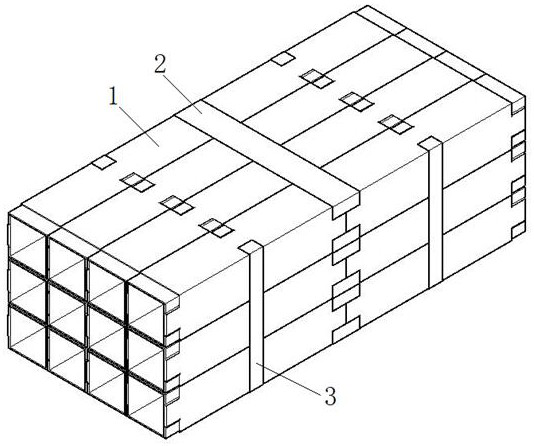

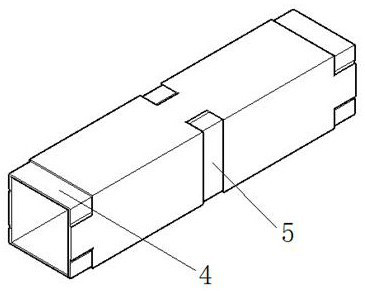

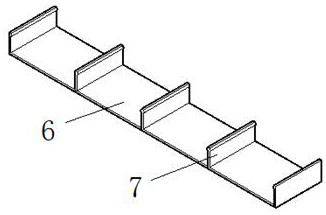

[0027] Such as figure 1 As shown, a GFRP lightweight prefabricated cable conduit includes several cable conduit modules, the several cable conduit modules are connected in series, and two adjacent cable conduit modules are fixed by two horizontal fasteners connection; the cable pipe arrangement module includes several cable pipes 1, several horizontal fasteners 2 and several vertical fasteners 3; the several cable pipes 1 are arranged in a matrix and combined to form multiple layers and multiple rows The cable tubes; the two ends of each layer of cable tubes 1 are fixedly connected by horizontal fasteners 2, and the horizontal fasteners 2 make the cable tubes 1 of each layer fixedly connected;

[0028] The two sides of each row of cable tubes 1 are fixedly connected by vertical fasteners 3, and the vertical fasteners 3 make each row of cable tubes 1 fixedly connected; the cable tubes 1, horizontal fasteners 2 and vertical fasteners Firmware 3 is made of lightweight, high-stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com