An attached truss-type concrete wall formwork support

A concrete wall and truss-type technology, which is applied to the joints of formwork/formwork/work frame, the preparation of building components on site, construction, etc., can solve problems such as high cost, and achieve saving components, saving man-hours, and load-carrying efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

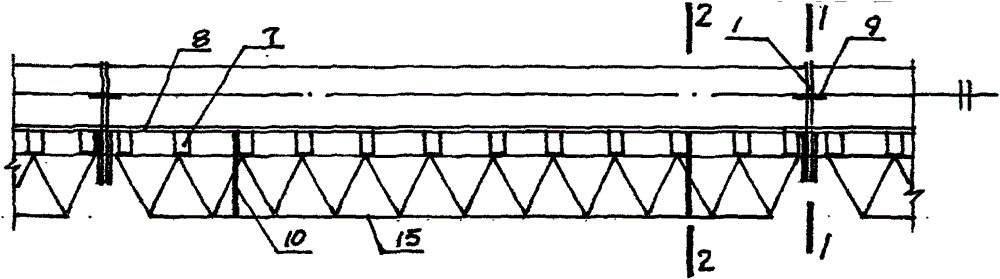

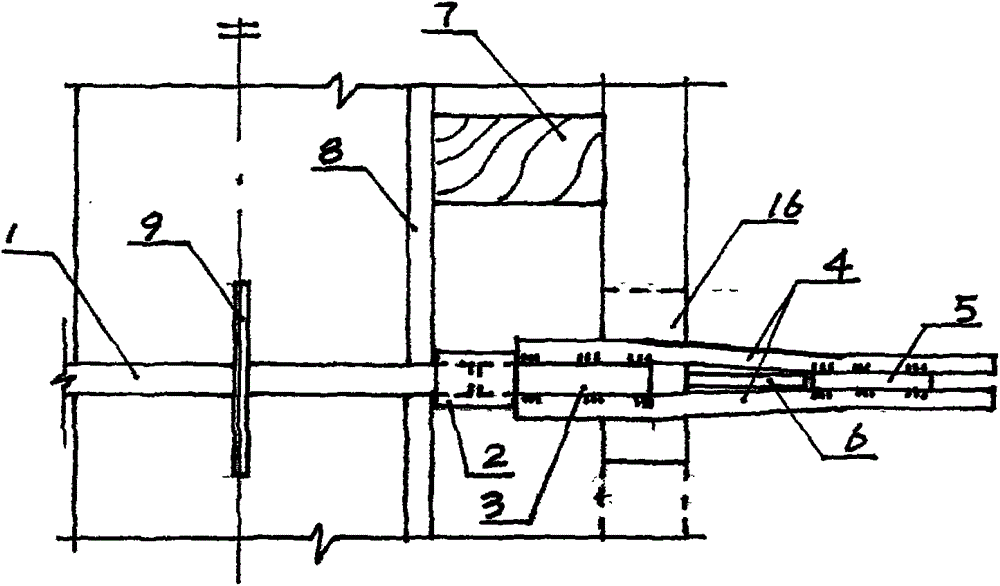

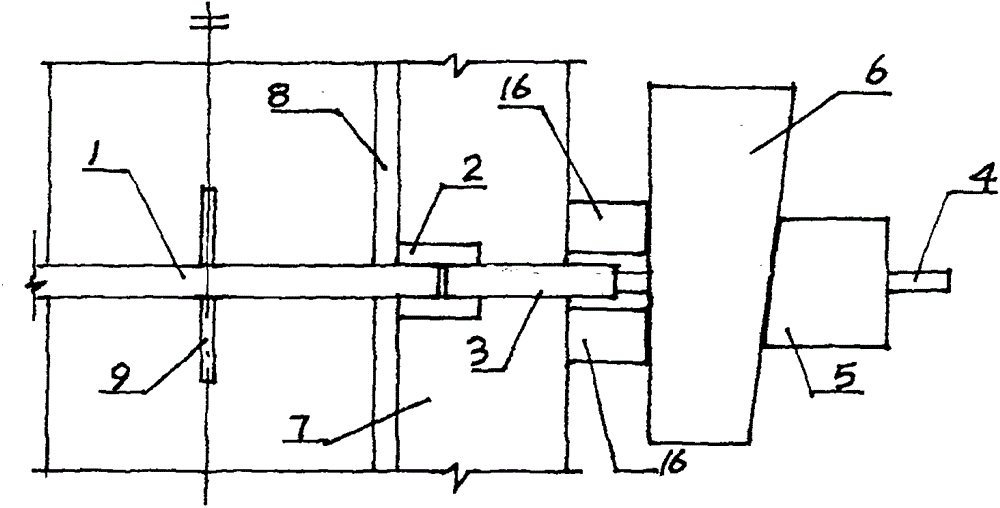

[0018] When setting up the formwork, the wall-through rod 1 passes through the wall formwork 8 on both sides, and the connecting sleeves 2 of the two external joints are respectively connected with the two ends of the wall-through rod 1; use nails to connect and fix the truss at the connection hole 13 on the upper chord of the truss Upper chord and back flute 7, the lower square pin 11 of the truss stabilizing bar 10 is inserted into the square hole of the truss lower chord connecting plate 14, rotated to the formwork direction to the dead point, connect and fix the truss stabilizing bar at the connecting hole 12 at the upper end of the truss stabilizing bar 10 10 and the back corrugated 7, the top chord ends 16 of two adjacent trusses 15 are overlapped up and down on the outer tie rods 4, and the wedge plate 6 is inserted between the wedge pads 5 of the outer joint and the ends 16 of the two adjacent trusses, and wedged tightly ; When removing the formwork, knock back the wedg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com