Heat exchange device of hydrogen catalytic combustor

A technology of catalytic burner and heat exchange device, which is applied to burners, gas fuel burners, combustion methods, etc., can solve the problems of ineffective use of heat, improve the efficiency of hydrogen catalytic burners, low hydrogen fuel air, etc. Modular assembly, good heat output stability, high heat utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

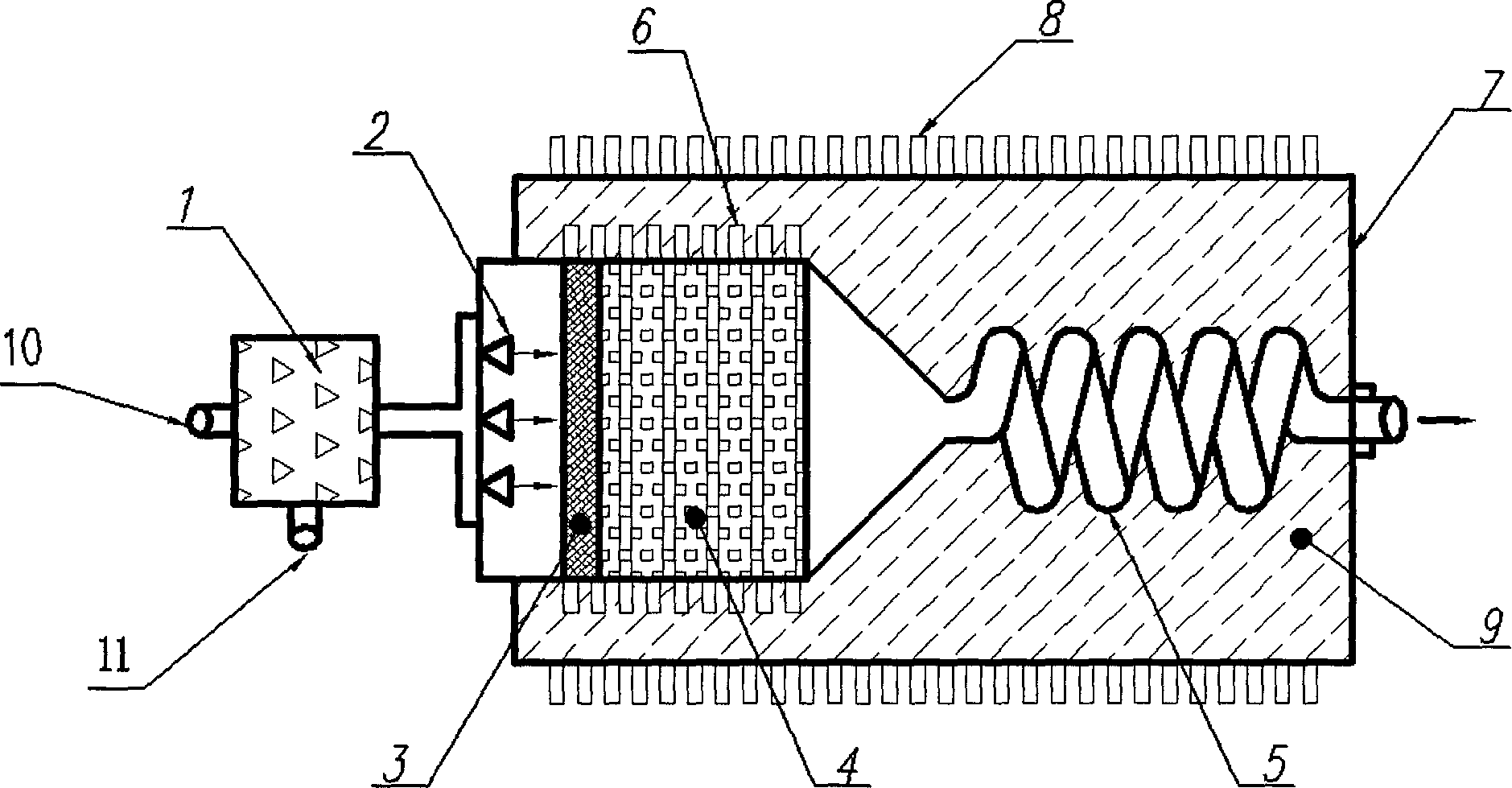

[0021] A heat exchange device for a hydrogen catalytic burner, comprising a heat exchange tank and a heat exchange tube. A hydrogen catalytic burner is built in the heat exchange tank, and burner fins are arranged outside the hydrogen catalytic burner. A heat exchange tube is installed at the outlet of the hydrogen catalytic burner. The heat exchange tube is a round copper or aluminum tube. The heat exchange tank is filled with a heat exchange medium. The heat exchange tube is located in the heat exchange medium. piece. The heat exchange medium is alkylnaphthalene type or alkyl biphenyl type or biphenyl and biphenyl ether low-soluble mixture type heat transfer oil. The heat utilization efficiency of the hydrogen catalytic combustion in this embodiment is 90%.

Embodiment 2

[0023] A heat exchange device for a hydrogen catalytic combustor, comprising a heat exchange tank 7 and a heat exchange tube 5 . A hydrogen catalytic burner is built in the heat exchange tank 7, and burner fins 6 are arranged outside the hydrogen catalytic burner. The hydrogen catalytic combustor is connected with a hydrogen and air premixer, and a low-temperature catalytic combustion layer 3 and a high-temperature catalytic combustion layer 4 are layered in the hydrogen catalytic combustor. A heat exchange tube 5 is installed at the outlet of the hydrogen catalytic burner, the heat exchange tube 5 is a circular copper or aluminum tube, and the heat exchange tube 5 is in a spiral shape. The heat exchange tank 7 is equipped with a heat exchange medium, the heat exchange tube 5 is located in the heat exchange medium, and the heat exchange tank 7 is equipped with heat exchange tank fins 8 . Heat exchange medium 9 is alkylnaphthalene type or alkylbiphenyl type or biphenyl and bip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com