Method for warm isostatic pressing control and system thereof

A temperature isostatic pressure, internal pressure technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as high difficulty and complex man-machine dialogue system, achieve convenient operation and realize equipment safety control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for warm isostatic pressing comprising:

[0040] Monitoring information parameters of warm isostatic pressing equipment;

[0041] Display the status of the warm isostatic pressing equipment;

[0042] Display the current alarm information of the warm isostatic pressing equipment;

[0043] Virtual operation of warm isostatic pressing equipment;

[0044] It is used to set the process parameters for automatic curve pressing and automatic cycle heating; and store the set process parameters;

[0045] Record the curve and operation process of process parameters, and provide historical data query.

[0046] The information parameters of the monitoring warm isostatic pressing equipment include: process parameters, motors, valves, upper end caps and frames of main engine cylinders, explosion-proof doors, and vacuum degree.

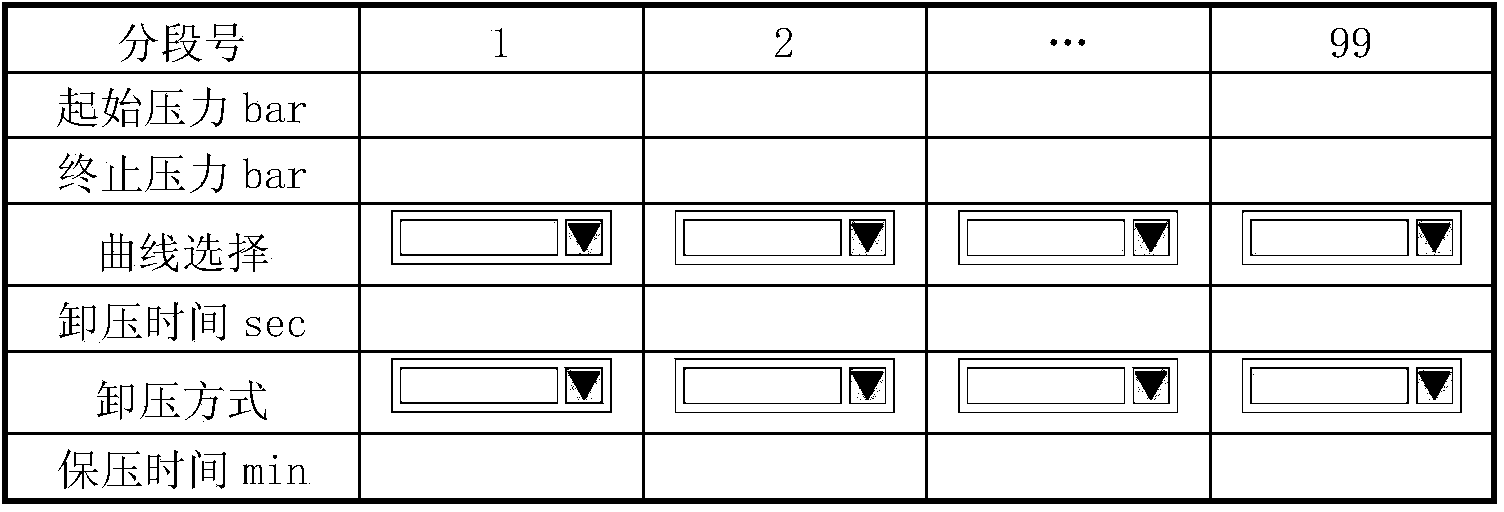

[0047] Specifically, the process parameters—mainly include the curve parameters required by the pressure control curve, such as initial pressure,...

Embodiment 2

[0052] A system for warm isostatic pressing comprising:

[0053] The monitoring module is used to monitor the information parameters of the warm isostatic pressing equipment;

[0054] The display module is used to display the state of the warm isostatic pressing equipment and display the current alarm information of the warm isostatic pressing equipment;

[0055] Virtual operation module for virtual operation of warm isostatic pressing equipment;

[0056] The parameter setting module is used to realize the setting of process parameters of automatic curve pressing and automatic circulation heating;

[0057] The storage module is used to store the set process parameters;

[0058] The record query module is used to record the curves and operation process of important process parameters, and provide historical data query.

[0059] The monitoring module includes: a unit for monitoring process parameters, a unit for monitoring motors, a unit for monitoring valves, a unit for moni...

Embodiment 3

[0064] In this embodiment, a man-machine dialogue device capable of realizing the near-net shape process of warm isostatic pressing is designed.

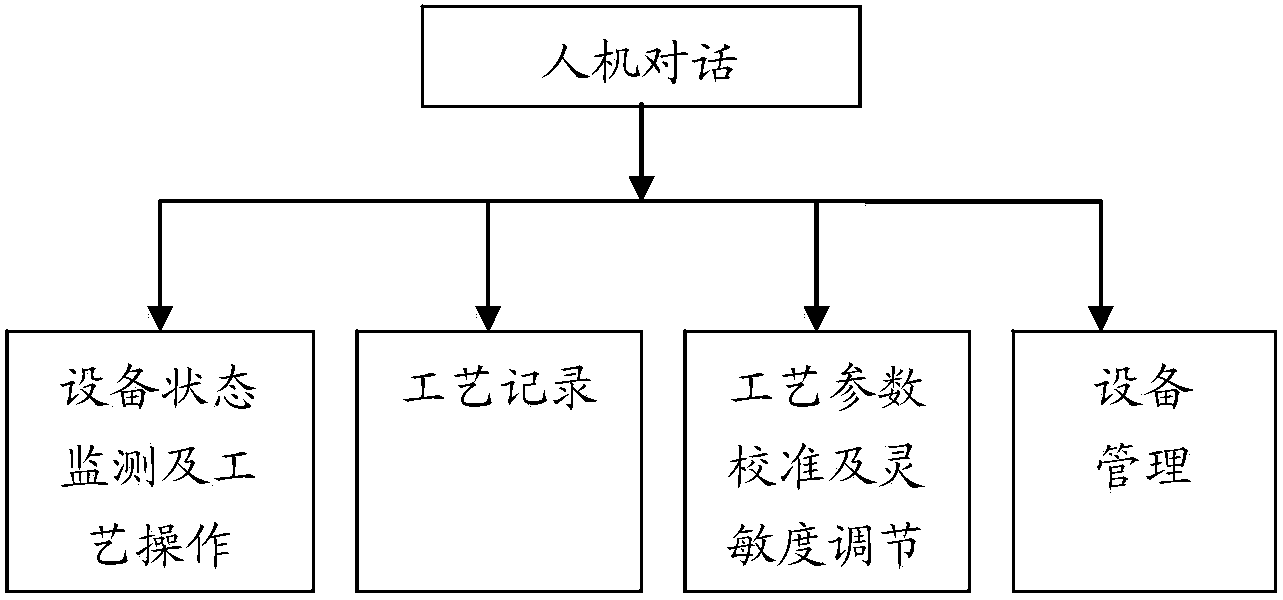

[0065] The device is mainly composed of four parts: equipment status monitoring and process operation, process record, process parameter calibration and sensitivity adjustment, and equipment management. figure 2 shown.

[0066] 1. Equipment status monitoring and process operation

[0067] Equipment status monitoring and process operation mainly realize the following functions:

[0068] a) Real-time display of equipment status, including process parameters, motors, valves, upper end cover and frame of main engine cylinder, explosion-proof door, vacuum degree and other information;

[0069] b) Display the status of the equipment, such as: manual / automatic, working / debugging and other status information;

[0070] c) Display the current alarm information of the device;

[0071] d) Virtual operation buttons, including "automatic pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com