Composition modeling method for combustion system based on numerical simulation and test operation data

A numerical simulation and test operation technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of single data source, affecting the accuracy of machine learning models, and the test data cannot involve all working conditions, etc., to improve The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] specific implementation plan

[0019] The invention provides a composite modeling method based on numerical simulation and test operation data. Be described below in conjunction with accompanying drawing.

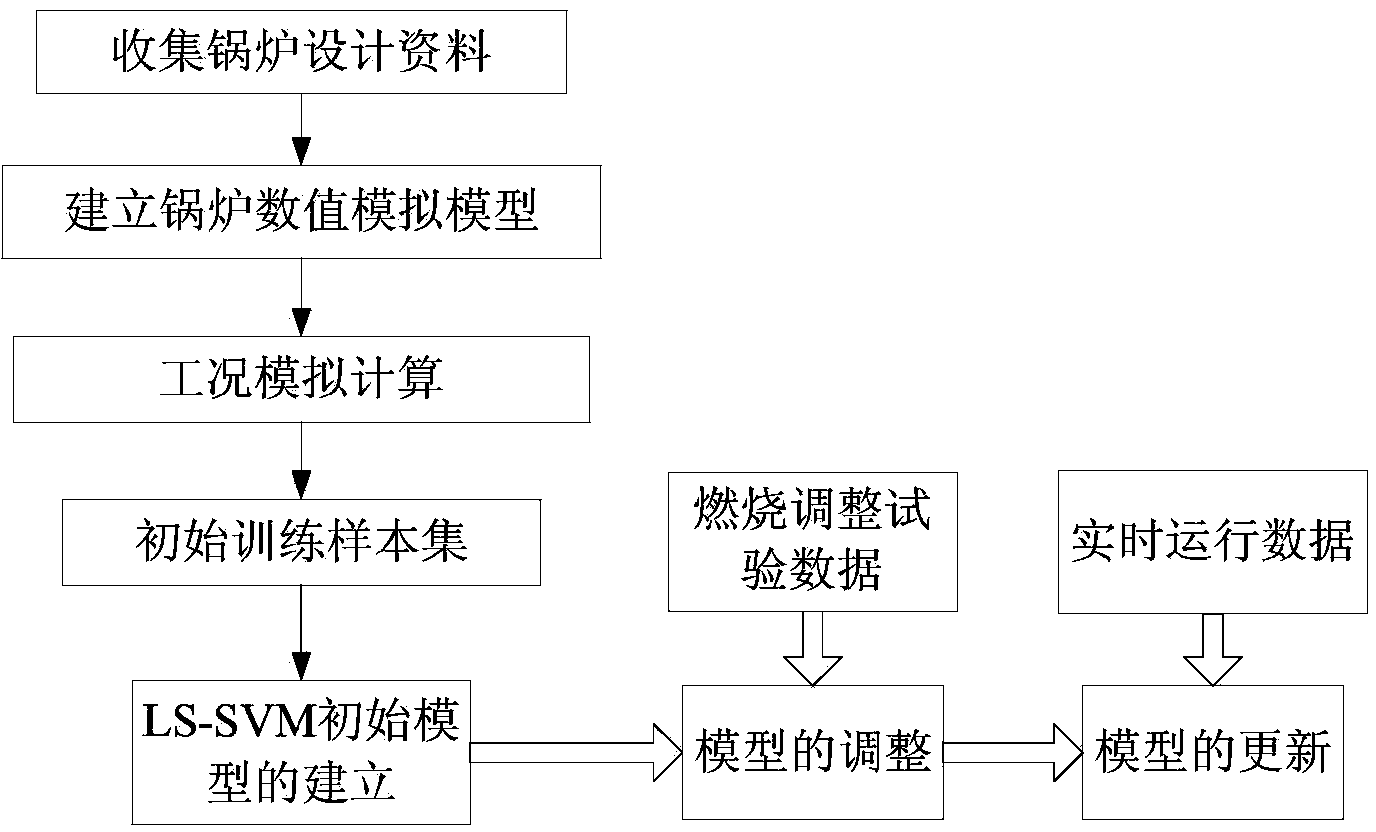

[0020] figure 1 Overall flow chart of the composite modeling method for the combustion system. Including the following main steps:

[0021] (1) The numerical simulation software fluent, which can be used for fluid heat transfer and combustion process, is selected to carry out numerical simulation modeling of the pulverized coal combustion process of the target boiler.

[0022] (2) Determine the input variables, and use the orthogonal method to give the number of training sample data groups and the values of each input variable. Use the numerical simulation model in step 1 to calculate the output corresponding to each set of inputs to obtain a list of variables.

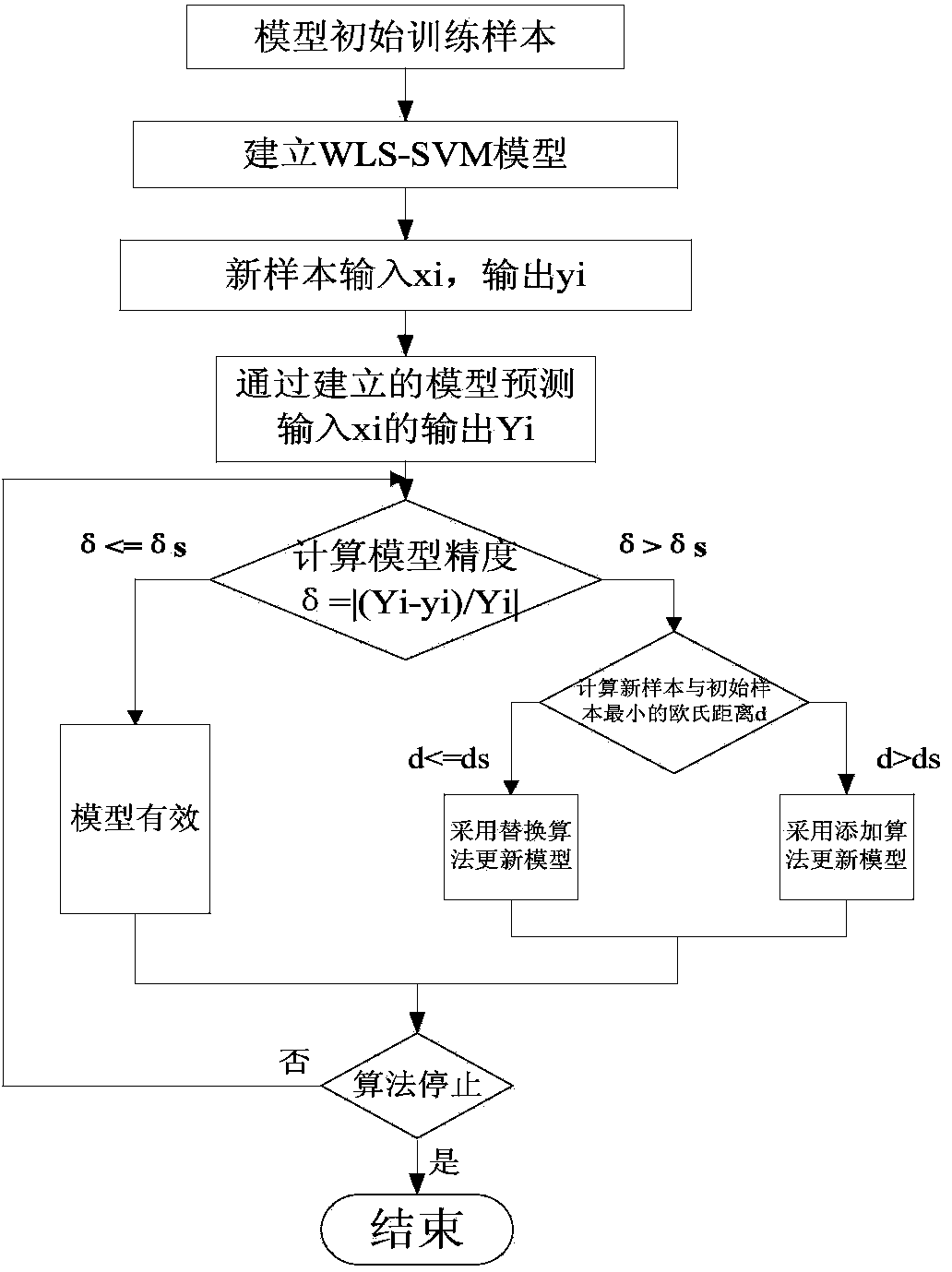

[0023] (3) Use the variable list in (2) as the training sample set to establish the initial mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com