Micro-strip line filter sharing substrate with YIG (Yttrium Iron Garnet) thin film material, and regulation method thereof

A technology of microstrip line filter and ferrite film, which is applied in the direction of waveguide devices, antennas, electrical components, etc., can solve the problems of increasing the difficulty and complexity of filters, increasing the size of filters, and unfavorable miniaturization development. , to achieve the effect of optimizing performance, optimizing structure and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

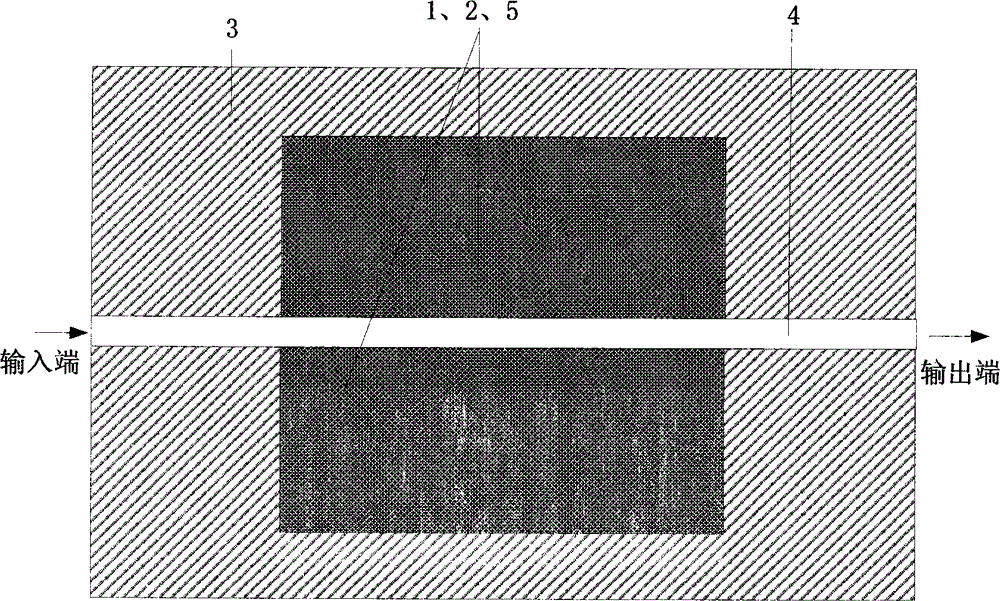

[0029] The magnetoelectric tunable microstrip line filter studied in the past such as Figure 5 As shown, the selected ferrite layer 2 (YIG thin film) and the GGG base material 3 for its growth must have the same size, and secondly, the common filter dielectric substrate must have a suitable dielectric constant and be able to combine with the ferrite layer. 2 (YIG film) for bonding, again to minimize the effect of the adhesive on the performance of the filter. This increases the difficulty and complexity in the design and manufacture of the filter, and the use of a ferrite material substrate requires a filter substrate, which relatively increases the size of the filter.

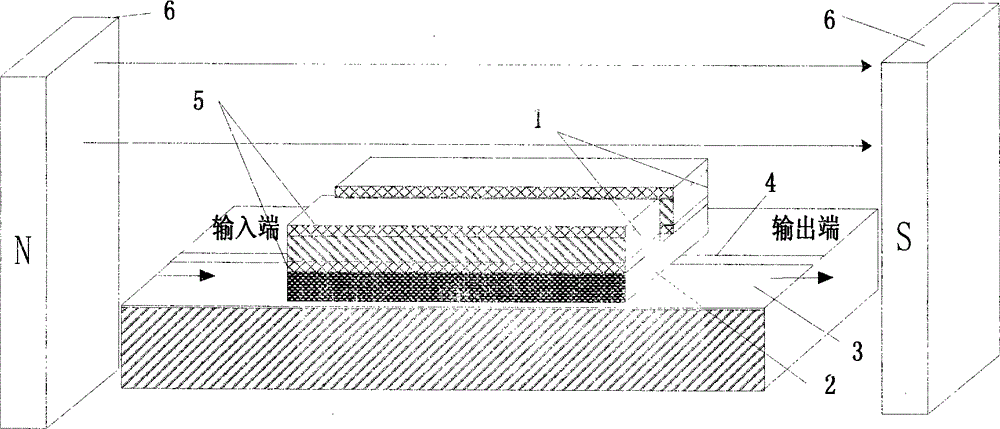

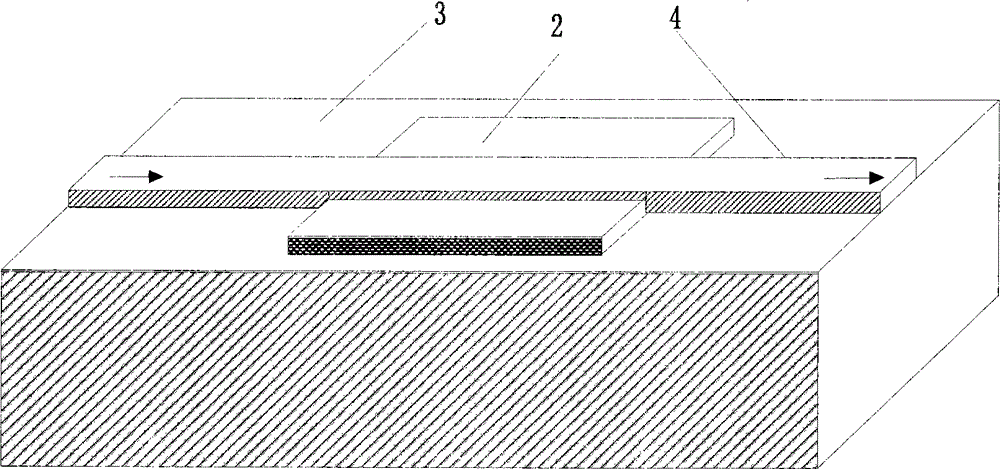

[0030]The magnetoelectric tunable microstrip line filter co-substrated with the ferrite thin film material in the present invention is as figure 1 , 2 , 4, the size of the GGG base material 3 used is 5.0mm×7.0mm×1.0mm. Two materials, YIG and PZT, are selected for the ferrite layer 2 and the piezoelectric l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com