Direct current motor without reversing device

A DC motor, non-commutation technology, applied in electromechanical devices, electrical components, usage of superconductor elements, etc., can solve the problems that the armature cannot generate DC power, the armature energization method is complicated, the use of DC generators, etc., to eliminate the magnetic field. The effect of hysteresis loss, easy control of speed regulation accuracy, and improved efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0035] In conjunction with Figures 1-15, the specific implementation of the design scheme mentioned in the present invention is as follows:

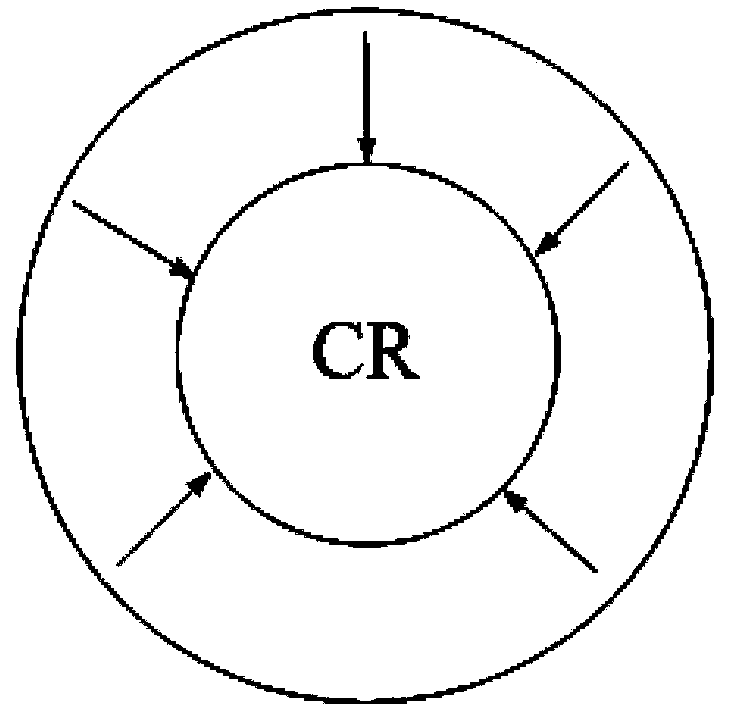

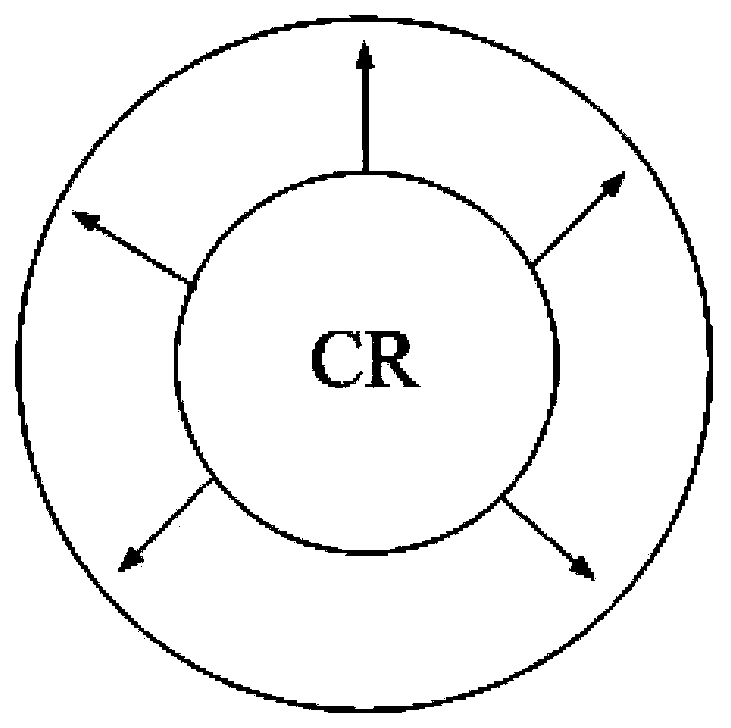

[0036] It can be seen from Figure 1 that a hollow cylindrical magnet (permanent magnet or superconducting block) is obtained by radial magnetization, and Figure 2 shows the distribution of magnetic force lines of the magnet, and the direction of the magnetic force lines is from the inside to the outside (ie The inner surface is N pole and the outer surface is S pole), or from the outside to the inside (that is, the outer surface is N pole and the inner surface is S pole), the magnetic field inside and outside the magnet is unidirectional and uniform. For ease of illustration and representativeness, the hollow cylindrical magnets mentioned below are permanent magnets or superconducting bulk materials.

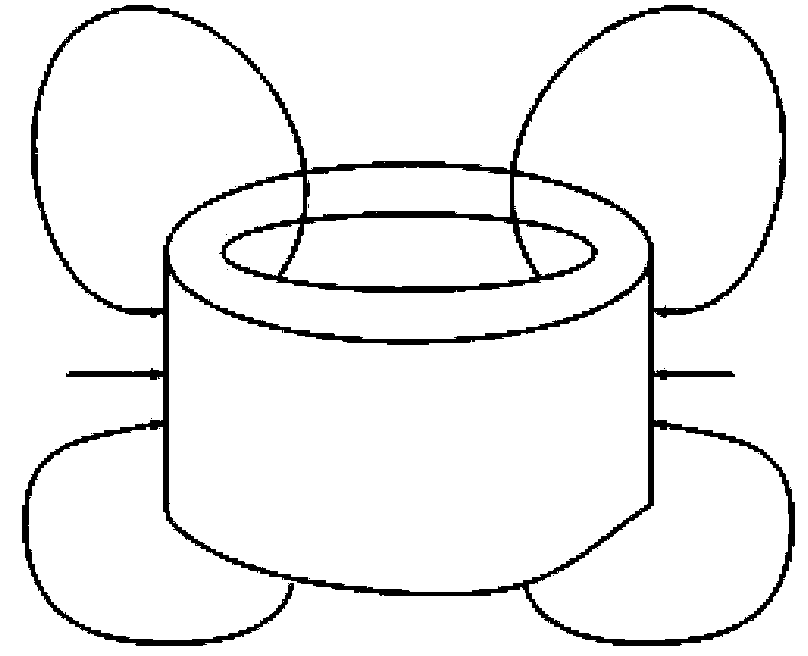

[0037] attached Figure 14 with attached Figure 15 The internal magnetic circuit of the motor is analyzed with the example that the ou...

Embodiment approach 1

[0038] Implementation Mode 1: Refer to the attached Figure 4 The overall axial sectional view of the middle motor, the specific implementation method of scheme one is: as shown in Figure 3, the squirrel-cage structure of the armature part is shown in the figure, including the squirrel-cage conductor 1 and the collector end ring 2, the squirrel-cage structure Both the cage conductor and the collector end ring are made of conventional materials (such as copper or cast aluminum), and the squirrel cage conductor 1 is inserted into the collector end ring 2 to form the armature part. The collector end rings 2 at both ends of the armature part lead out the current inflow path 601 and the current outflow path 602 respectively, and lead out the induced current to the terminal 603 outside the motor casing. The excitation part adopts the hollow cylindrical permanent magnet 3, which is closely connected with the rotating shaft 5 through the laminated silicon steel sheet 4 to form the exc...

Embodiment approach 2

[0039] Embodiment 2: The materials and components used in Embodiment 2 are exactly the same as those in Embodiment 1, and the structure has been adjusted. The difference from Embodiment 1 is that the excitation part is fixed, and the armature part rotates with the shaft. The excitation part adopts a hollow cylindrical permanent magnet 3, which is fixed inside the motor casing 6 to generate a static magnetic field in space. The inner magnetic field of the hollow cylindrical permanent magnet is a unidirectional, uniform and constant magnetic field. The armature part is located on the rotating shaft, and the squirrel-cage structure of the armature part is shown in Figure 3, in which the squirrel-cage conductor 1 and the collector end ring 2 are closely connected to the rotating shaft 5 through the laminated silicon steel sheet 4. In particular, the collector The brush device 9 is specially designed and manufactured on both sides of the end ring 2. One end of the brush device 9 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com