Liquefied gas regasification device and regasification gas manufacturing method

A technology of liquefied gas and regasification, which is applied to container discharge methods, gas/liquid distribution and storage, gas treatment/storage effects, etc., can solve problems such as difficult miniaturization, achieve simple structure, and reduce the possibility of freezing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach )

[0044] The first embodiment of the present invention will be described below.

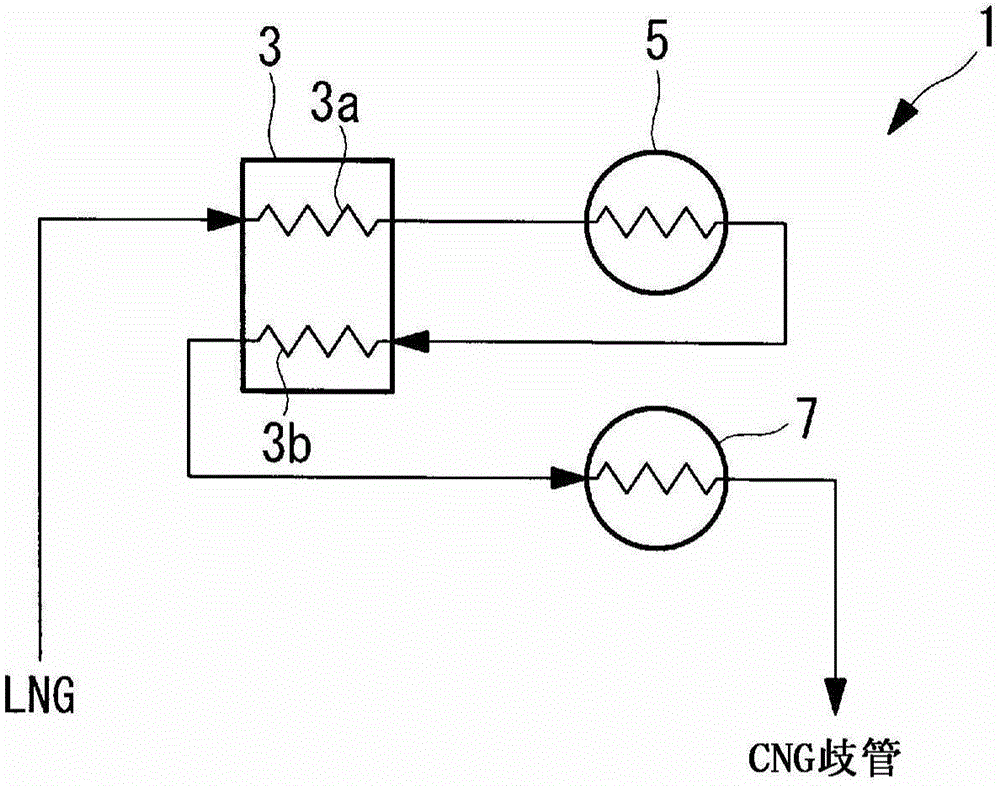

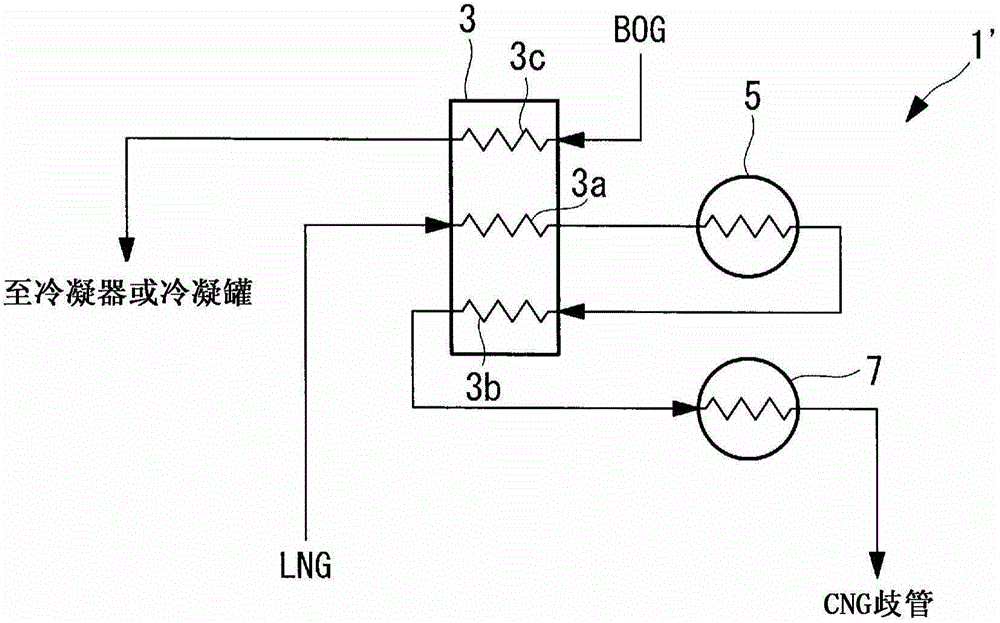

[0045] Install LNG storage equipment (liquefied gas storage equipment) on ships such as FSRU (Floating Storage and Regasification Unit) and FPSO (Floating Production Storage and Offloading), floating bodies at sea, and LNG ships. figure 1 A regasification apparatus 1 is shown for performing regasification when supplying LNG (liquefied gas) derived from an LNG storage tank (liquefied gas storage tank) of the LNG storage facility to a desired place.

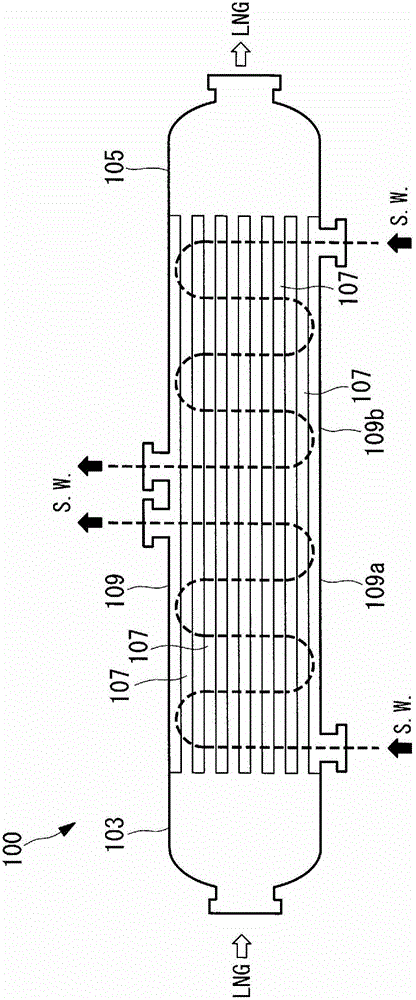

[0046] Such as figure 1 As shown, the regasification device 1 has: a preheating heat exchanger 3 for preheating LNG; a first shell-and-tube heat exchanger (first heat exchanger) 5 for preheating The liquefied gas is regasified using seawater or clean water; the second shell-and-tube heat exchanger (second heat exchanger) 7 regasifies the liquefied gas introduced from the preheating heat exchanger 3 using seawater or clean water.

[0047] The heat ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com