Balance beam impact combine harvester grain flow measuring device and grain flow measuring method

A combine harvester and grain flow technology, which is applied to the harvester, detects fluid flow by measuring pressure difference, and volume/mass flow generated by mechanical effects, etc. It can solve the problem of large error in impact grain flow measurement and eliminate vibration Interference, the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

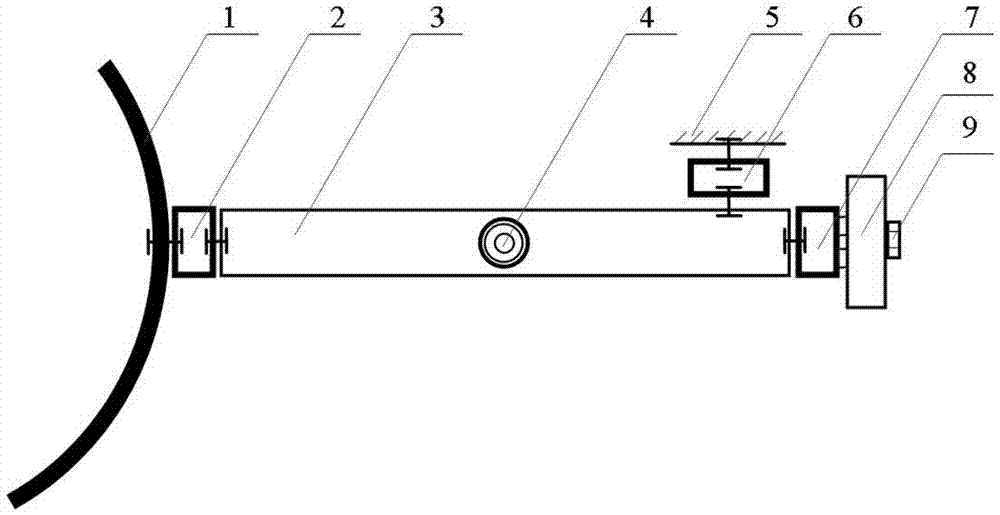

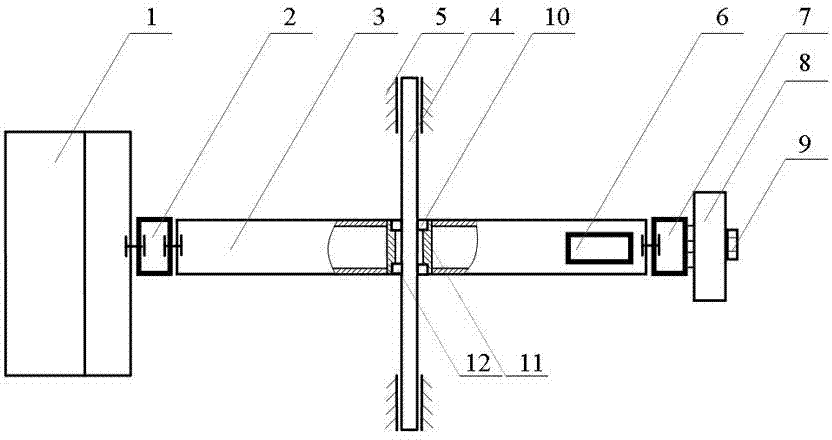

[0028] Please refer to the structure of the balance beam impact combine harvester grain flow measuring device figure 1 , 2 , consisting of an arc-shaped impact plate 1, a first horizontal tension-compression sensor 2, a bracket 3, a support shaft 4, a vertical tension-compression sensor 6, a second horizontal tension-compression sensor 7, a balance weight 8, and an adjustment bolt 9, and the horizontally arranged bracket 3. It can rotate around the support shaft 4. One end of the bracket 3 is connected to the arc-shaped impact plate 1 through the first horizontal tension-compression sensor 2, and the other end is sequentially provided with a second horizontal tension-compression sensor 7, a balance weight 8, and an adjustment bolt 9; The upper or lower surface of the bracket 3 near the end of the second horizontal tension-compression sensor 7 is connected to the vertical tension-compression sensor 6 . A through hole is arranged in the middle part of the support 3, and an axl...

Embodiment 2

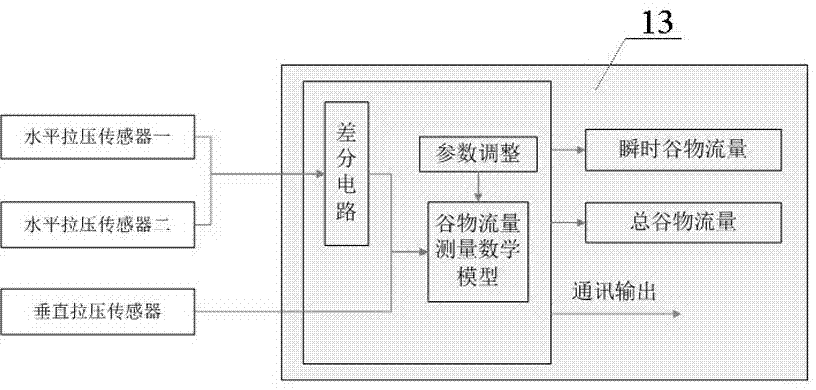

[0031] The measuring principle of the grain flow measuring device can be found in image 3 .

[0032] The grain flow measurement method using the above-mentioned balance beam impact combine harvester grain flow measurement device includes the following steps:

[0033] Step 1. Establish a grain flow measurement model

[0034] Step 1.1. Lead the grain with a known flow rate to the direction of the arc-shaped impact plate 1, record the vertical component force of the grain impact measured by the vertical tension and pressure sensor 6, and the first horizontal component force measured by the first horizontal tension and pressure sensor 2 , the second horizontal force component measured by the second horizontal tension-compression sensor 7;

[0035] Step 1.2, performing a differential operation on the first horizontal component force and the second horizontal component force to obtain the horizontal component force of the grain impacting the arc-shaped impact plate 1;

[0036] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com